Deep repairing method for air circulation machine bearing shell

A technology for air cycle machines and bearing shells, which is applied in the field of air cycle machines, can solve problems such as the high price of new parts of shells and bearing support components, failure to install bearings or seals normally, damage to aluminum compressor shells, etc., to achieve The mechanical structure is safe and reliable, meets the requirements of use, and improves the effect of usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

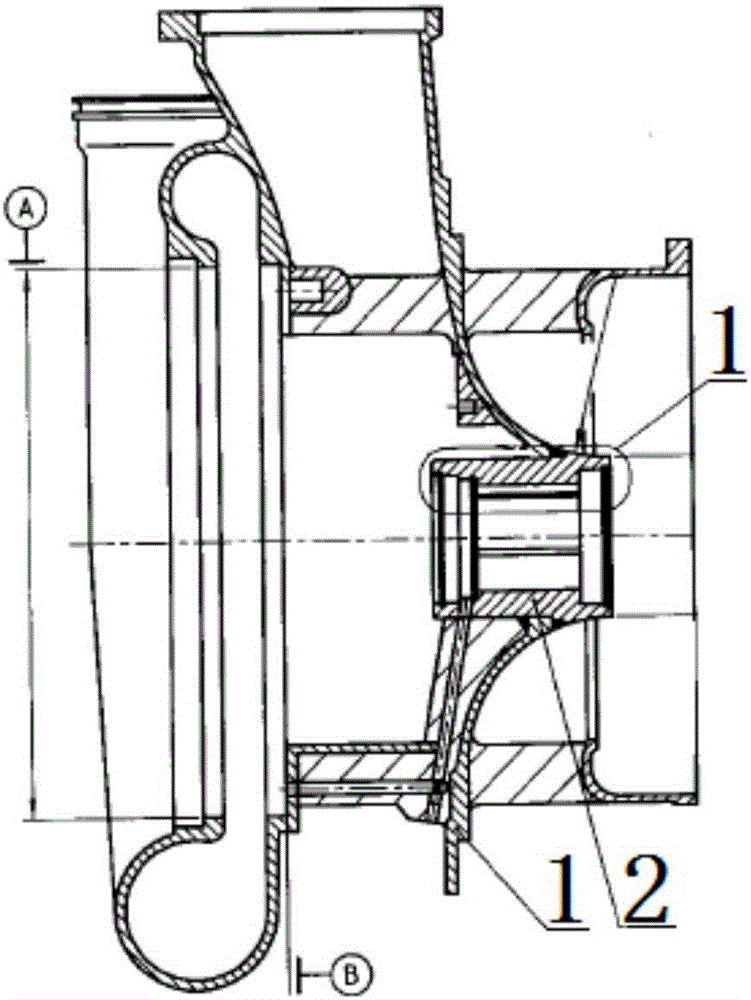

[0044] Referring to the accompanying drawings, it can be seen that the method for deep repair of the bearing housing of the air cycle machine is characterized in that it includes the following steps:

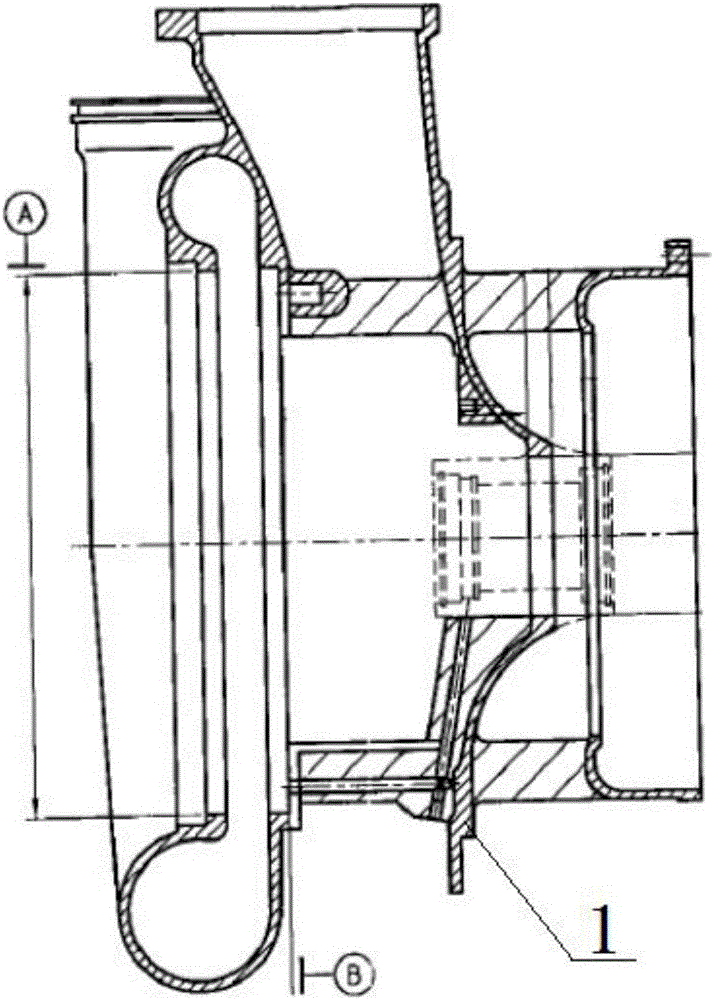

[0045] Step 1: Remove the damaged part of the compressor casing 1 (such as figure 1 As shown in the figure, the dotted line part is the part that should be removed in the original shell);

[0046] Step 2: Carry out flaw detection inspection on the compressor shell 1 (technical standard implements ASTME-1417);

[0047] Step 3: Select the 6A02 forged aluminum alloy material (material technical standard: GB / T 3191-1998) which is similar to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com