Multi-cutter-head household garbage crushing structure

A domestic waste, multi-cutter technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

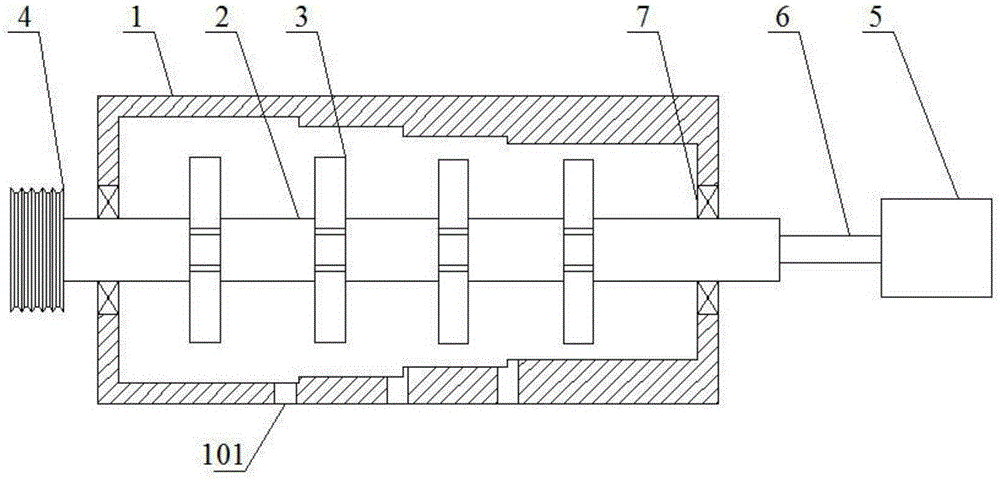

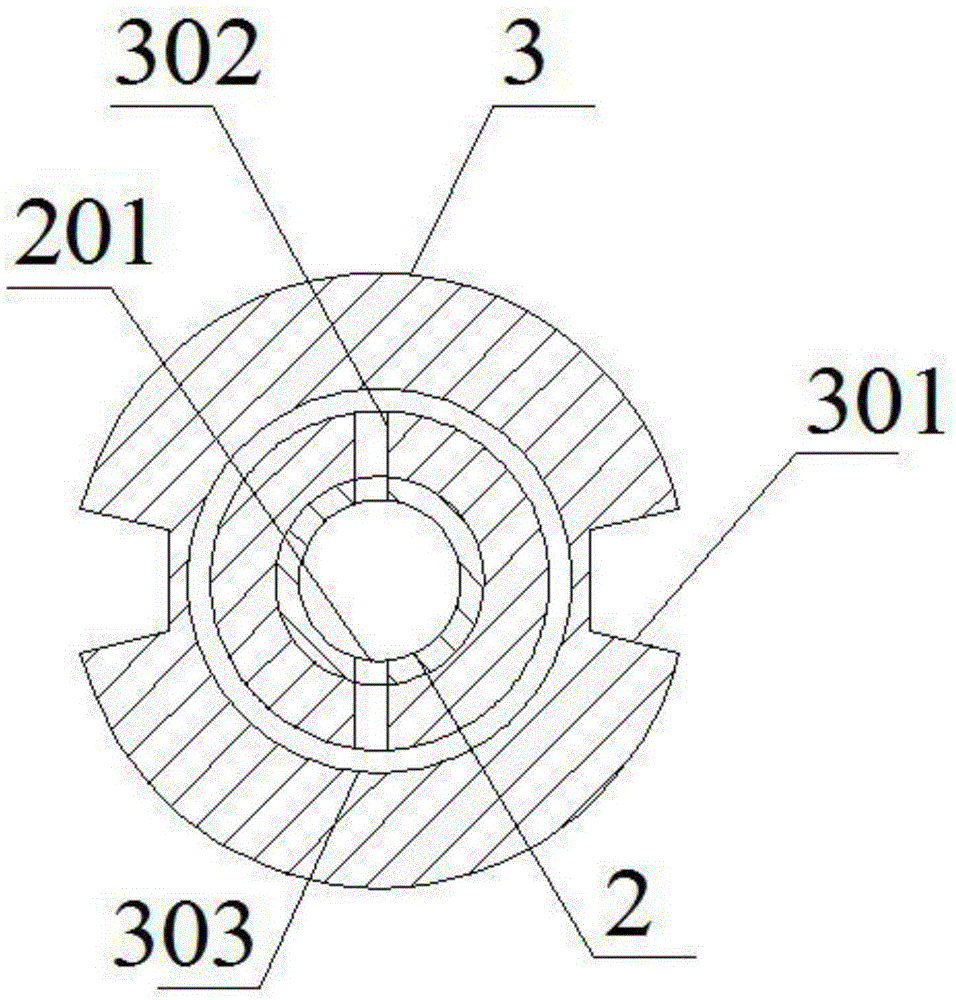

[0030] like figure 1 and figure 2 As shown, the multi-cutter domestic waste crushing structure includes a crushing chamber 1, a rotating shaft 2, a cutter head 3, a pulley 4, a water pump 5 and a connecting pipe 6; the rotating shaft 2 is arranged in the crushing chamber 1, and the rotating shaft 2 includes a first end and a second end. Two ends, the interior of the rotating shaft 2 is a hollow structure, the first end of the rotating shaft 2 is closed, and the second end of the rotating shaft 2 is open; The end runs through the wall of the crushing chamber 1, the inlet end of the connecting pipe 6 is connected to the outlet of the water pump 5, the outlet end of the connecting pipe 6 is inserted into the second end of the rotating shaft 2, the outlet end of the connecting pipe 6 is coaxial with the rotating shaft 2, and connected There is a gap between the outer surface of the tube 6 and the inner surface of the rotating shaft 2; a plurality of cutter heads 3 are located in...

Embodiment 2

[0035] like figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes two support bearings 7, and the two support bearings 7 are respectively arranged at the first end and the second end of the rotating shaft 2 and pass through the cavity of the crushing chamber 1 wall.

Embodiment 3

[0037] like figure 1 As shown, this embodiment is based on Embodiment 1, and the bottom of the crushing chamber 1 is provided with a plurality of water seepage holes 101 .

[0038] Water seepage holes 101 are provided to facilitate the discharge of liquid in the garbage and reduce the load on the cutter head 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com