Manual grinding machine

A grinding machine and grinding roller technology, applied in the field of food processing, can solve the problems of easy accidental injury of the blade to the user, poor food taste, fear of water, etc., and achieve the effects of convenient and quick operation, not easy to accidentally hurt, and easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

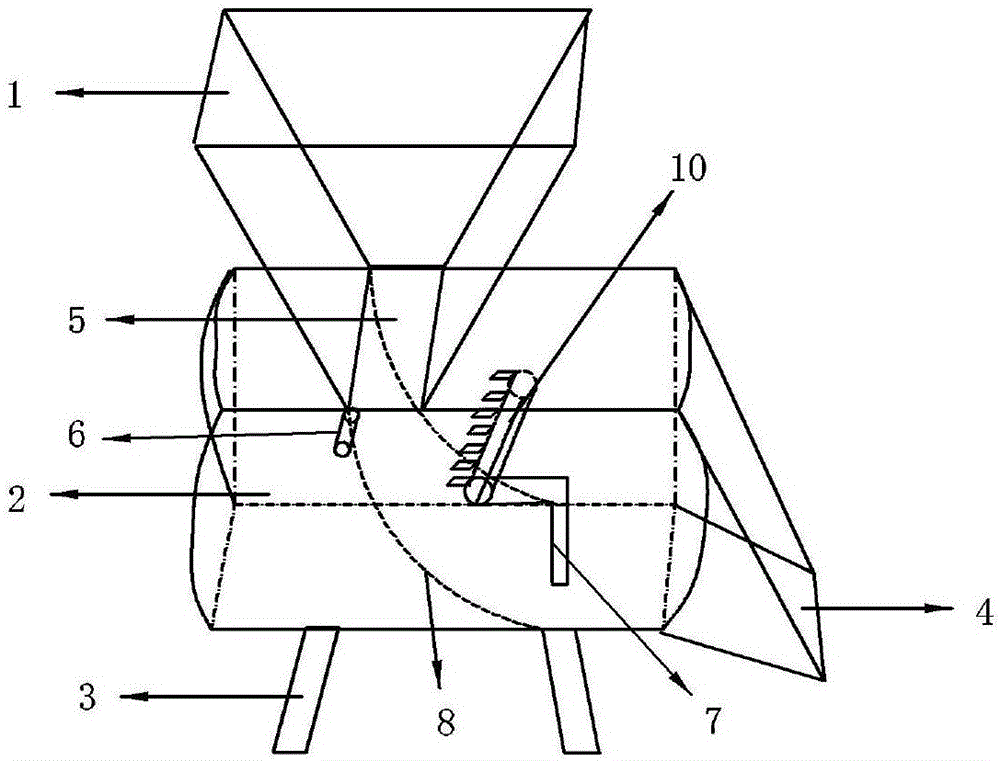

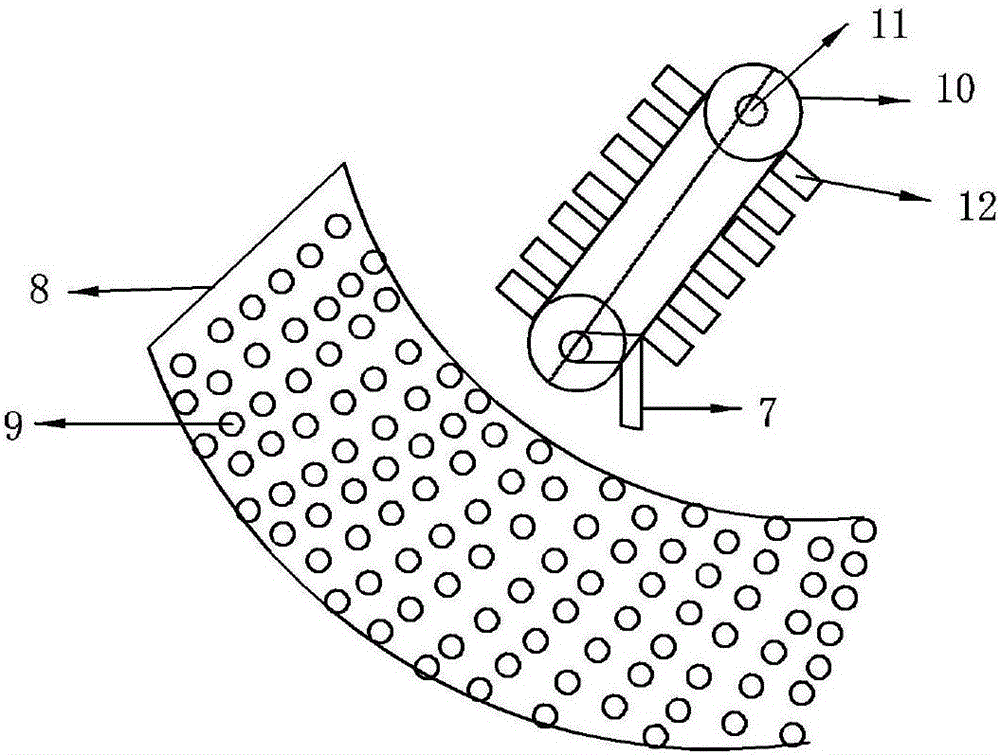

[0016] As shown in the figure, a manual grinder includes a funnel 1 and a grinding chamber 2, the funnel 1 is in an inverted trapezoidal shape, and a baffle 5 is provided at the bottom end, and a grinding disc 8 and a grinding roller 10 are arranged in the grinding chamber 2 , the grinding roller 10 is connected with a handle 7, and the handle 7 is turned to make the grinding roller 10 and the grinding disc 8 run-in. .

[0017] The grinding disc 8 is inclined downward from left to right, that is, it is a concave slope, and several grinding cutter heads 9 are arranged on its surface, so that the processed food is ground back and forth with the rotation of the grinding roller in the inclined grinding disc, and the material is discharged. It is easy for the food to slide out.

[0018] The center of the grinding roller 10 is provided with a main shaft 11, and its surface is provided with a plurality of grinding teeth 12, so that the food is grinded back and forth between the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com