Energy-saving diversion type cyclone separator

A technology of cyclone separator and spiral diversion, which is applied in the direction of separating sediments by centrifugal force, can solve the problems such as the influence of descending swirl flow and poor separation effect of swirl flow, and achieve the effect of reducing pressure drop, low kinetic energy requirements, Good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

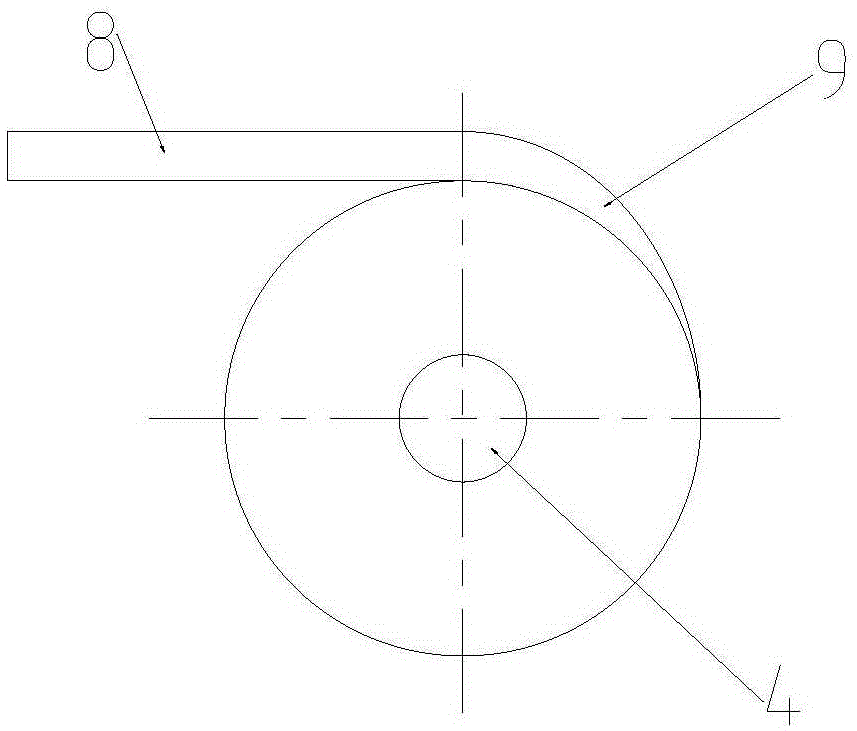

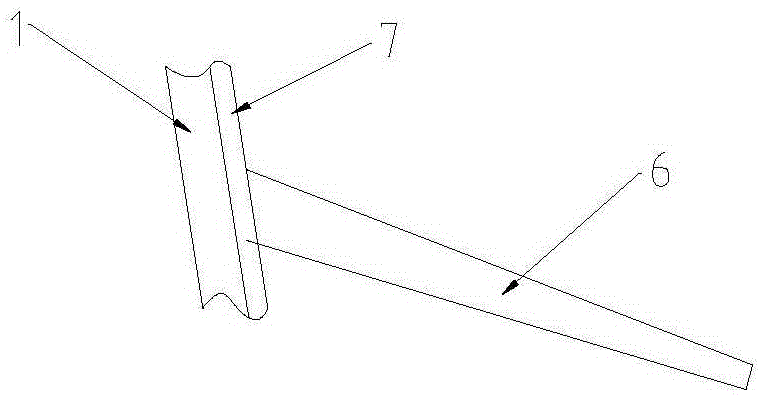

[0019] Such as figure 1 Shown is a schematic structural view of an embodiment of the energy-saving cyclone separator of the present invention. The energy-saving cyclone separator of this embodiment includes a cyclone separator body, the cyclone separator body includes a cylindrical section 1 at the upper part and a conical section 2 at the lower part, the bottom of the conical section 2 is provided with a sewage outlet 3, The top of the cylinder section 1 is provided with an overflow port 4, and the side wall of the cylinder section 1 is provided with a liquid inlet 5, and the liquid inlet 5 is provided with a liquid inlet pipe 8, and the liquid inlet pipe 8 is close to the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com