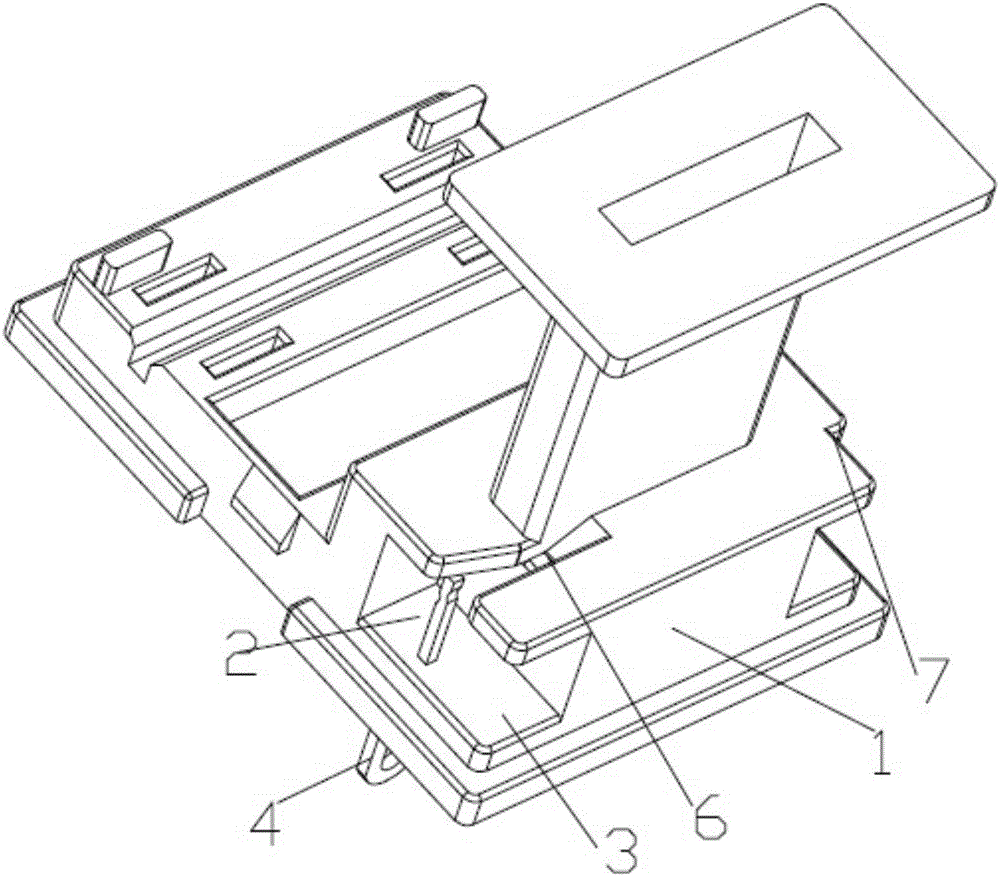

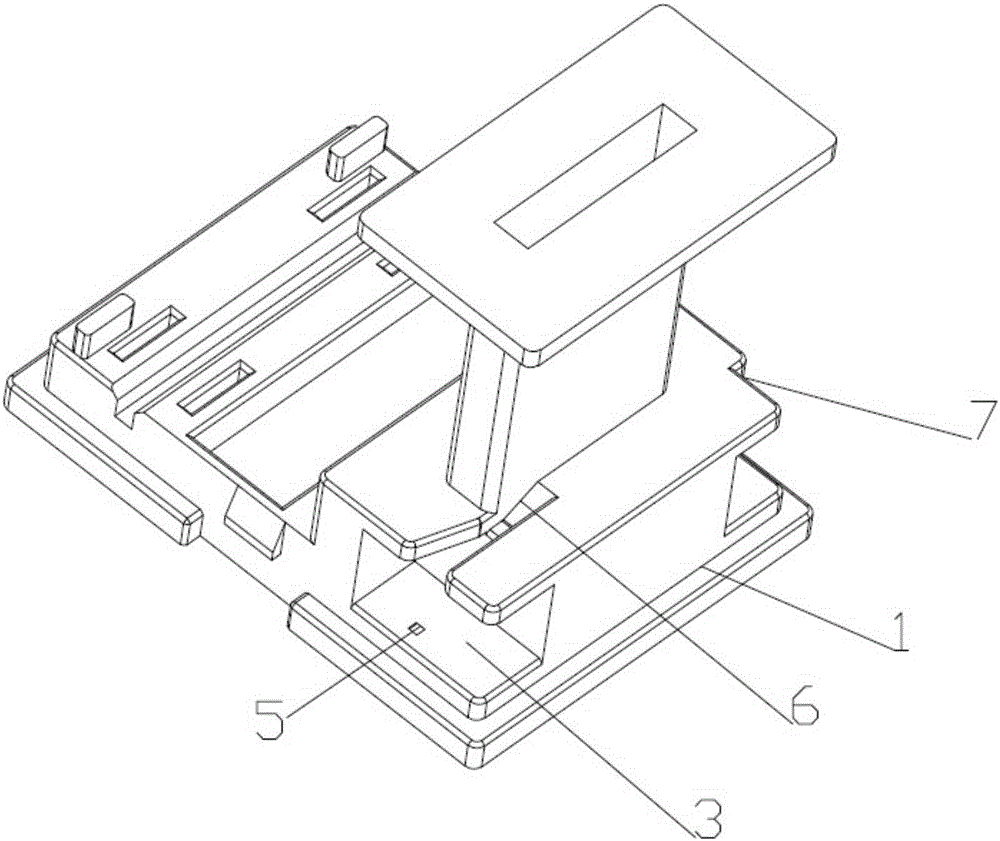

Wire winding device of relay, relay comprising same, and mounting method of wire winding device of relay

A technology of winding device and installation method, which is applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of bruising the paint layer and reducing the surface smoothness of winding coils, etc., and achieves convenient installation, simple structure, and avoids naked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] A relay with a winding device, the relay also includes a housing 14, a contact system 15, a push card 16 and a magnetic circuit assembly 17, the contact system 15 is arranged on the push card 16, the push card 16 and the magnetic circuit The assembly 17 is arranged on the installation base 1, the magnetic circuit assembly 17 drives the contact system 15 to operate as a moving contact by pushing the card 16, the cover of the housing 14 is connected to the installation base 1, and the magnetic circuit assembly 17 It includes a U-shaped iron core 18, an armature 19 and a yoke 20. The yoke 20 and the U-shaped iron core 18 are die-cast integrally. One end of the U-shaped iron core is inserted from the bottom surface of the installation base 1. One end of the armature 19 is connected to the U-shaped The U-shaped iron core 18 is connected, and the other end of the armature 19 and the end of the yoke 20 on the U-shaped iron core 18 form a magnetic pole surface.

[0039]In Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com