Detection table for detecting hub runout

A testing table and wheel hub technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of runout error, waste of resources, inconvenient to take due to large gravity, and achieve the effect of preventing errors and facilitating detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

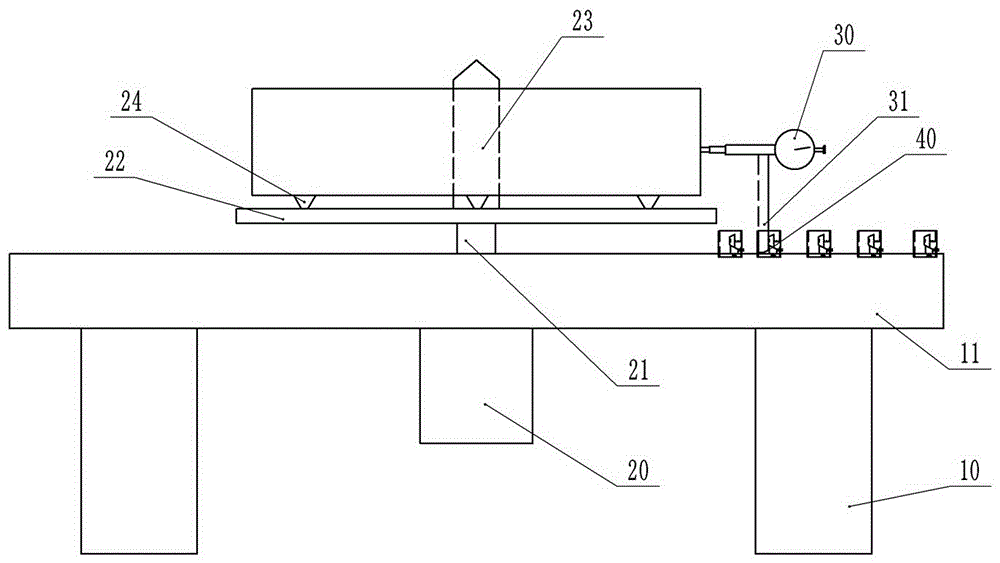

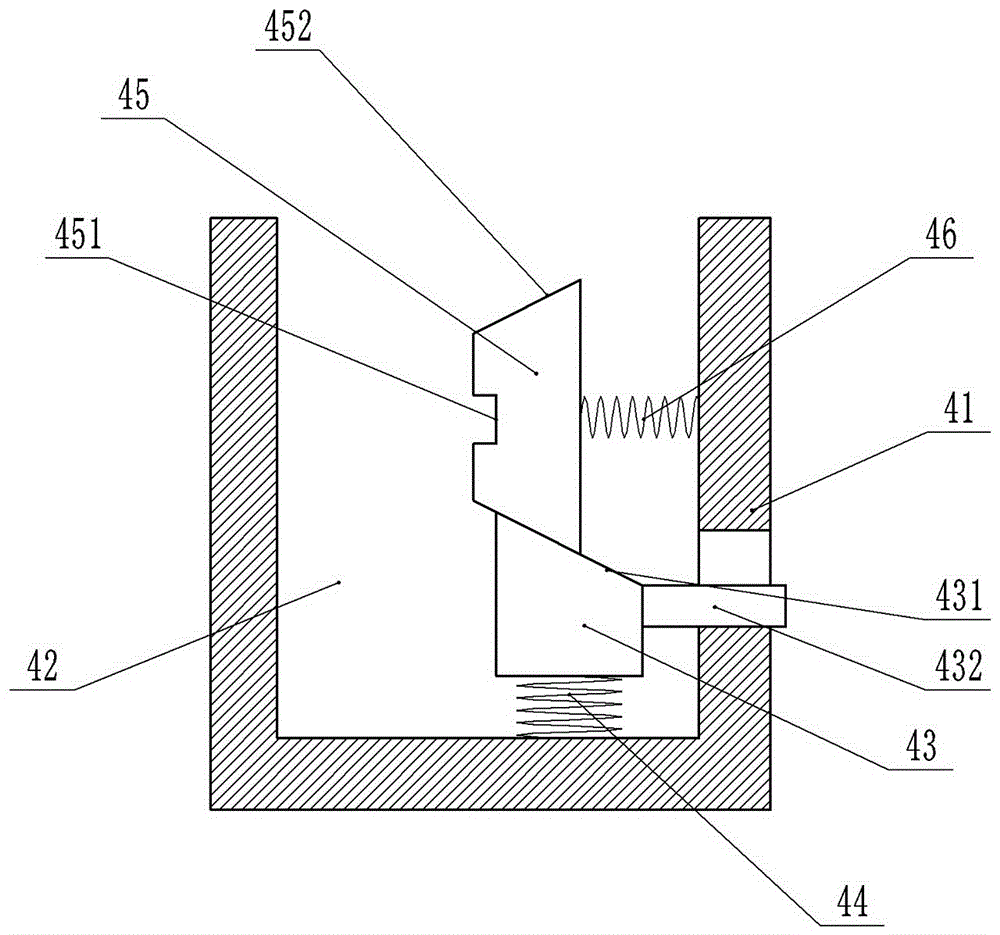

[0017] The reference signs in the drawings of the description include: bracket 10, workbench 11, motor 20, rotating shaft 21, turntable 22, positioning shaft 23, suction cup 24, dial gauge 30, fixed rod 31, third inclined plane 32, bayonet pin 33 , dial gauge fixing unit 40, housing 41, cavity 42, moving rod 43, second slope 431, support block 432, first elastic member 44, slope block 45, card slot 451, first slope 452, second Elastic member 46.

[0018] Such as figure 1 , figure 2 As shown, a detection platform for detecting hub runout includes a bracket 10, a workbench 11, a rotating shaft 21, a motor 20, a dial gauge 30 and a plurality of dial gauge fixing units 40, and the workbench 11 is fixed on the upper end of the bracket 10 , the motor 20 is fixed on the lower end of the workbench 11, the workbench 11 is provided with a rotating shaft 21 vertically upwards, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com