Limiting mechanism for part production

A technology of limit mechanism and parts, which is applied in the field of equipment manufacturing, can solve the problems of inconvenient disassembly of fixing devices, reduce service life, reduce work efficiency, etc., and achieve the effect of stable and safe equipment placement, consolidating the fixing effect and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

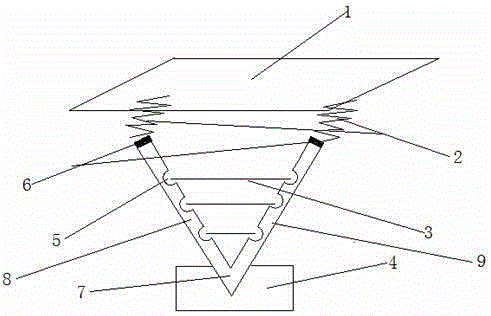

[0015] A limit mechanism for part production, comprising a limit block 1 and a limit support 7, the limit support 7 is a V-shaped limit support, and the bottom of the limit support 7 is provided with a protective baffle 4; Seat 7 comprises limit support leg a8 and limit support leg b9, the distance between limit support foot a8 and limit support leg b9 is 60 °, limit support leg a8 and limit support leg The upper end of b9 is cushioned with a buffer gasket 6; the two ends of the limit block 1 are provided with an elastic device 2, and the limit block 1 is connected with the buffer gasket 6 through the elastic device 2, and the limit support leg a8 and the limit support leg b9 There are three symmetrical transverse U-shaped grooves 5 on the top, and the U-shaped grooves 5 are placed with tough plates 3 .

[0016] The above descriptions are preferred embodiments of the present invention, and should not be used to limit the scope of rights of the present invention. It should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com