Double-plug series connection application method of reciprocating pump and high-efficiency liquid pump applying method

An application method and technology of reciprocating pump, applied in the direction of pump, pump element, pressure pump, etc., can solve the problems of complex structure, affecting energy utilization efficiency, increasing energy consumption structure cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

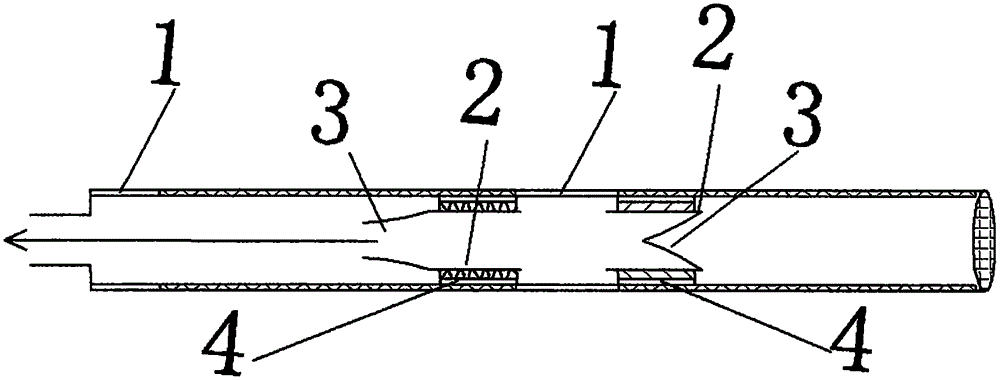

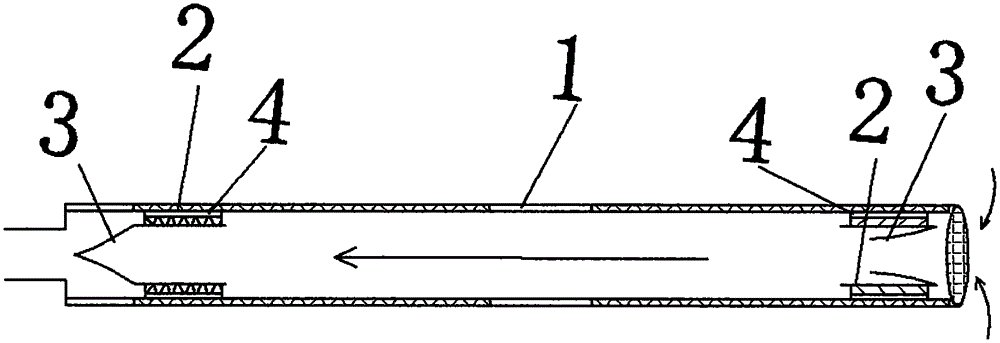

[0008] Such as figure 1 , in the cylinder liner of a pump body 1, two sets of hollow plungers or pistons 2 with one-way valves 3 in the same direction are used in series one after the other, and two sets of linear motors 4 act on the power of the two sets with one-way valves 3 respectively. On the hollow plunger or piston 2 of valve 3, make them reciprocate in opposite directions, cooperate with each other, and push the liquid flow in turn to do work. When two sets of hollow plungers or piston 2 with one-way valve 3 are pushed relative , the one-way valve 3 on the front hollow plunger or piston 2 near the water outlet is opened, the one-way valve 3 on the rear hollow plunger or piston 2 is closed, and the fluid is pushed out of the water outlet by the rear hollow plunger or piston 2, such as figure 1 As indicated by the arrow in the figure 2 In the second middle, when the two sets of front hollow plungers or piston 2 are pushed in the opposite direction, the one-way valve 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com