Row pile anchoring cement soil pile continuous wall supporting structure and construction process thereof

A technology of cement-soil piles and support structures, which is applied in the direction of foundation structure engineering, excavation, construction, etc., and can solve the problems of small contribution of anchor bolt earth pressure, high difficulty of support and support construction, and large anchor bolt axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

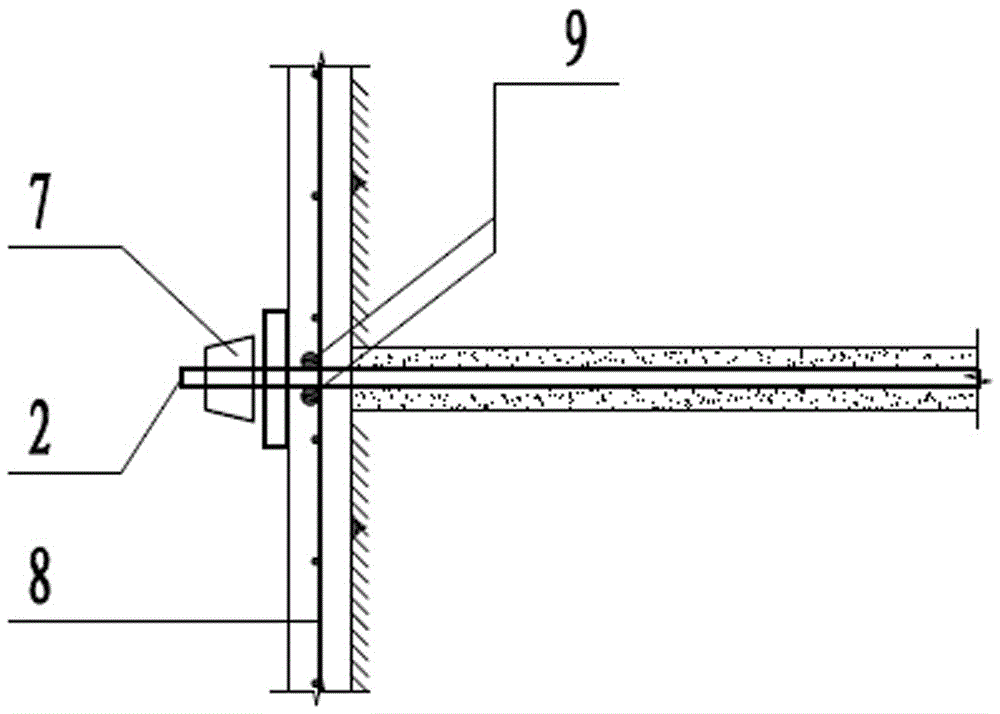

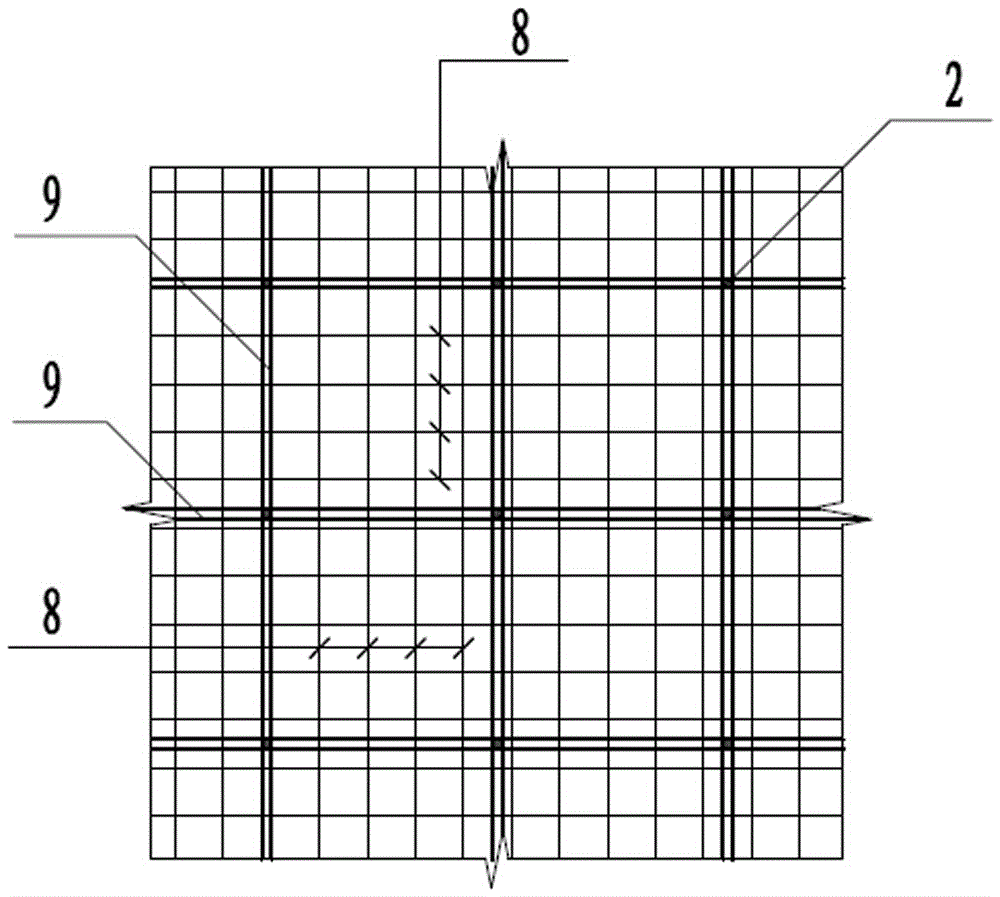

[0028] The depth of the foundation pit is 15m, and there are two layers of basement 6 outside the foundation pit. The design adopts row pile anchor pull cement-soil pile continuous wall support structure, such as figure 1 , 2 , 3, including concrete surface 3, row of piles 1, full-length bonded anchor rod 2 and single row or multiple rows of cement-soil pile continuous wall 5, the concrete surface 3 is arranged along the side wall of the foundation pit, and the concrete surface 3 The thickness is 100mm, with two-way A8 steel bars 8 inside, and the spacing is 200mm. The row of piles 1 is a concrete row of piles 1. m; the distance between the rows of piles and the 5th axis of the cement-soil pile continuous wall is 7.5m.

[0029] The full-length bonded anchor rods 2 are vertically arranged in 4 rows, each with a length of 8m, a diameter of 150mm, and an inclination angle of 15°. Each row of full-length bonded anchor rods is arranged at intervals of 1.5m; the full-length bonded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com