A Method for Overweight Vehicles Crossing Simply Supported Girder Bridges

A simply supported girder bridge and bridge crossing technology, applied in bridges, bridge construction, bridge maintenance, etc., can solve the problems of high construction technology requirements, cumbersome construction procedures, and long construction period, and achieve high construction technology requirements and cumbersome construction procedures , the effect of long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below.

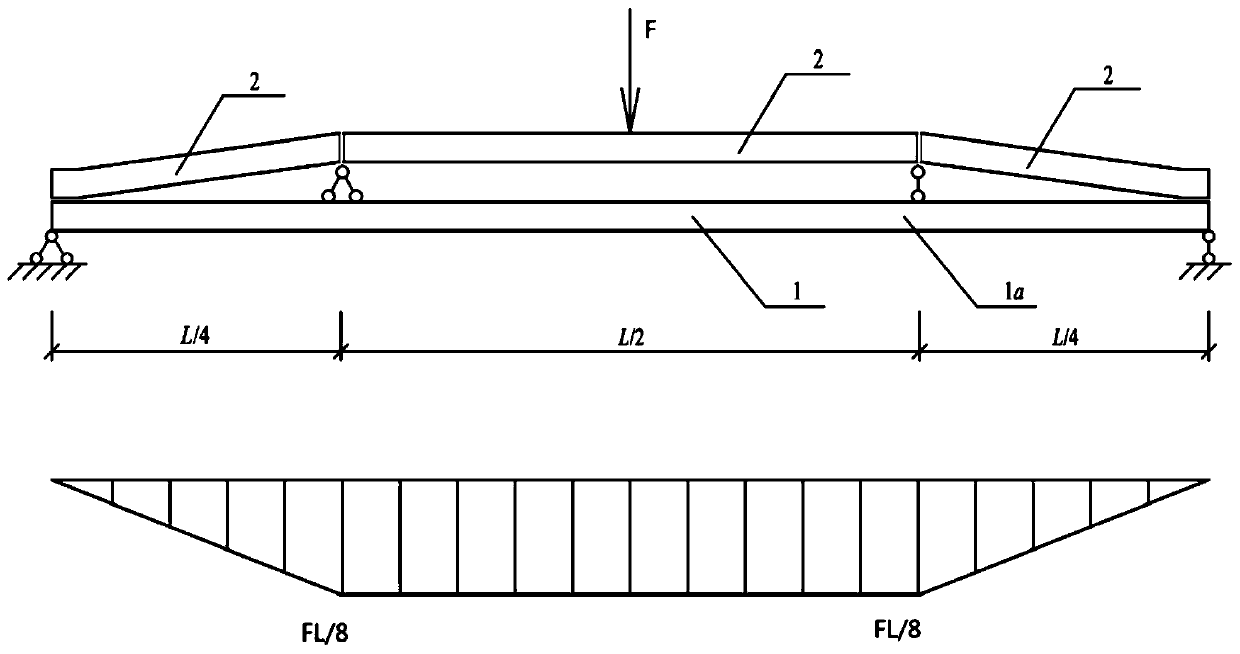

[0045] Calculate the ultimate flexural bearing capacity M of the main girder of a simply supported beam bridge with a span L=20000mm and a bridge deck width of 8m u =6000kNm, the maximum bending moment M produced by the dead load in the main span of the simply supported girder bridge h= 3250kNm.

[0046] An overweight vehicle needs to pass through the simply supported beam bridge, the weight of the overweight vehicle is F=700kN, and the left and right wheelbase of the overweight vehicle is 2.0m.

[0047] If the present invention is not adopted, and the overweight vehicle is directly allowed to pass the simply supported girder bridge, then the maximum bending moment produced by the overweight vehicle in the main girder span of the simply supported girder bridge is M c =FL / 4=700×20 / 4=3500kNm, then M u =6000kNmh +M c )=6750]kNm, the sum of the maximum bending moment generated by the dead load and overwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com