Automatic electrostatic cloth processing equipment

A kind of processing equipment and fully automatic technology, which is applied in the direction of non-woven fabrics, textiles, papermaking, acupuncture machines, etc., can solve the problems of polluted fiber products, etc., and achieve the effect of good vertical needling degree, convenient operation and use, and fast operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

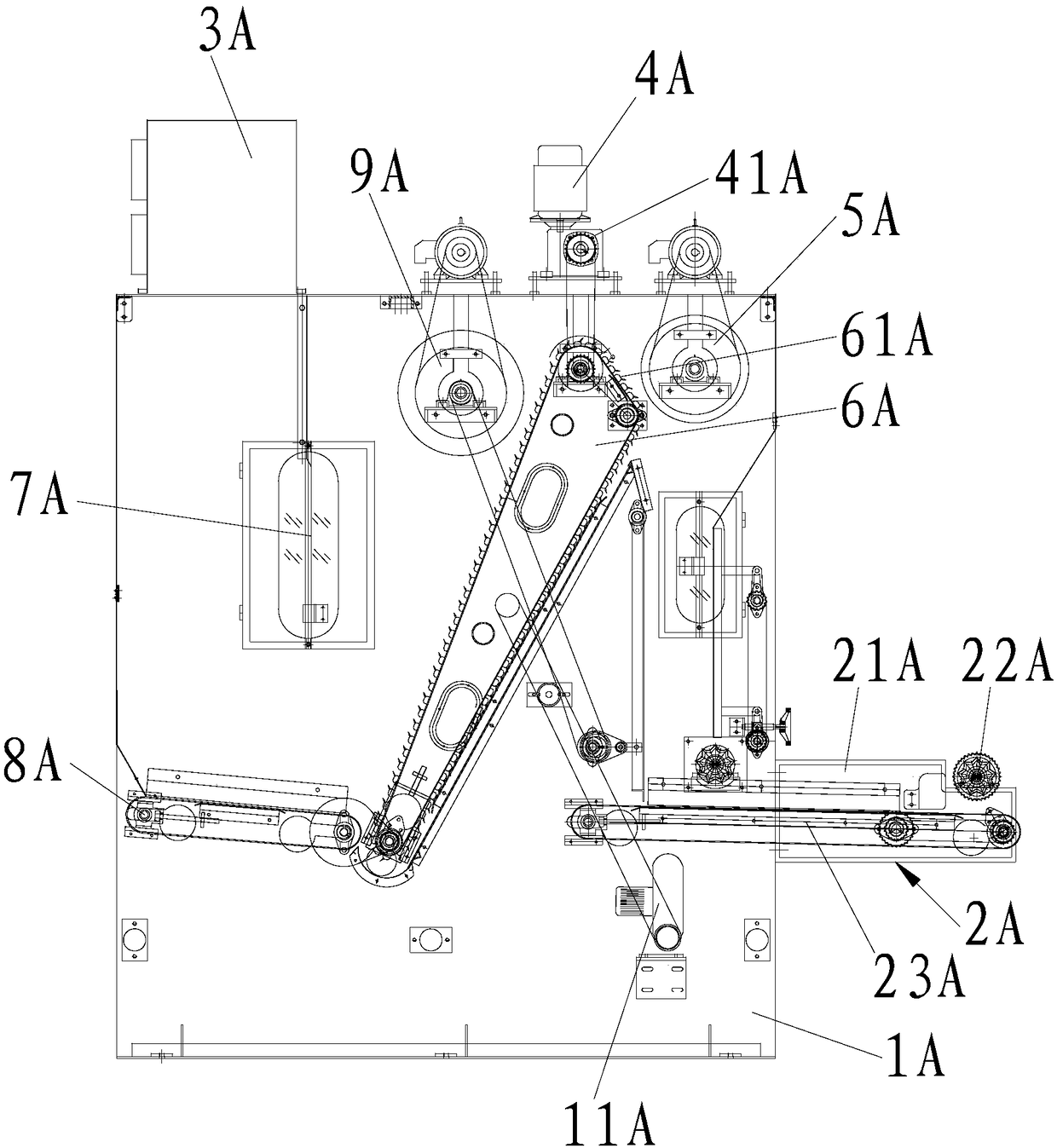

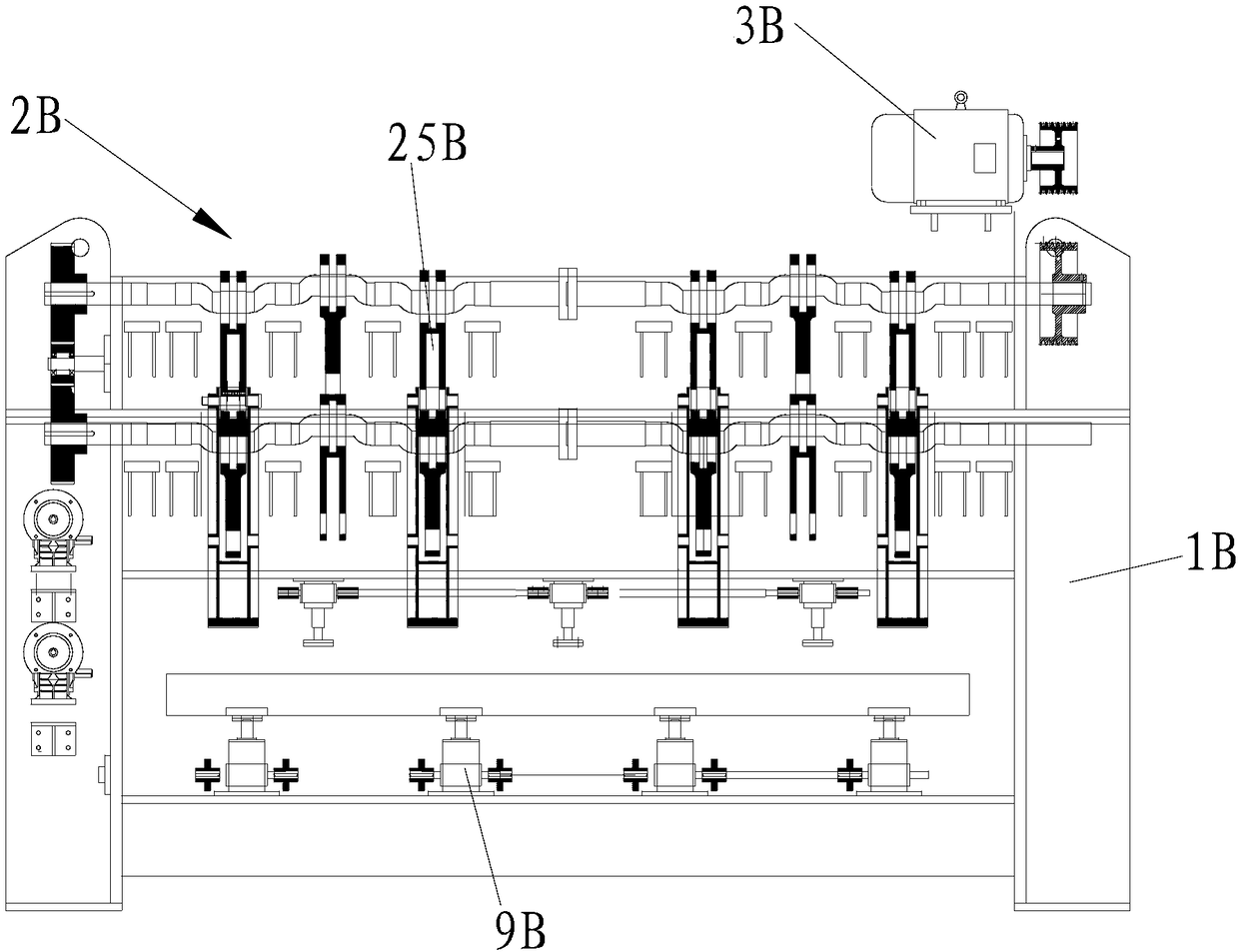

[0018] See Figure 1 to Figure 3 Shown: the present invention comprises carding frame body 1A, acupuncture device 1B, and the upper end of carding frame body 1A is provided with input box 3A, carding machine motor 4A, and carding machine motor 4A is provided with transmission 41A, and carding frame body 1A A transition shaft 2A is provided on one side of the transmission 41A, and a sprocket 61A is connected to the output end of the speed changer 41A. The sprocket 61A is provided with a needle curtain 6A, and the two sides of the needle curtain 6A are respectively provided with a beating roller 5A and an evening roller 9A. The input end of the curtain 6A is provided with a cotton-feeding leather plate 8A, a vibrating plate is provided at the cotton-feeding leather plate 8A, a blower 11A is provided at the lower end of the vibrating plate, and an exhaust pipe is arranged on the blower 11A, and one end of the exhaust pipe is arranged on the needle curtain. at 6A.

[0019] The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com