Twistless feeding system for weaving flattened weft yarns

A weft and weaving technology, applied in the field of twistless feeding systems, can solve problems such as yarn defects, save raw material consumption, improve product quality, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

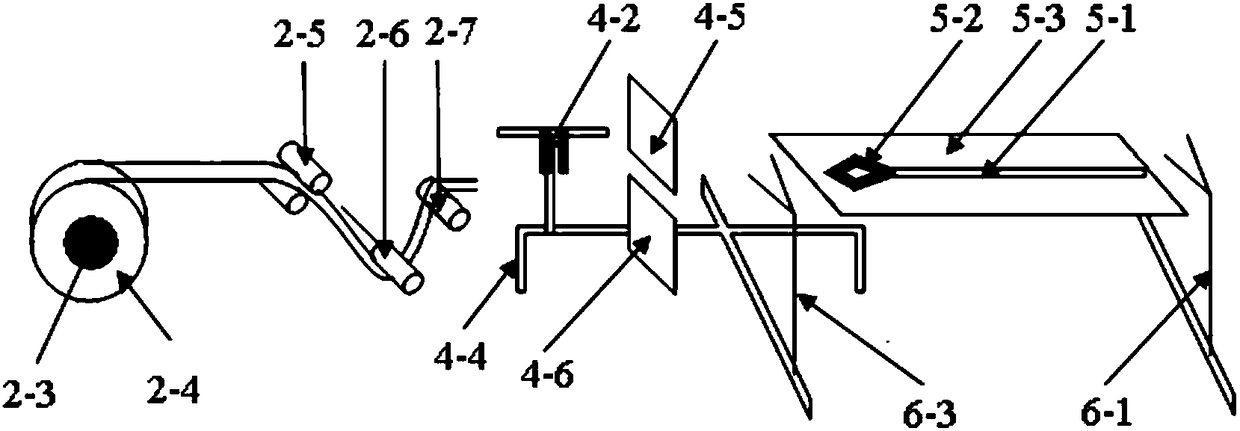

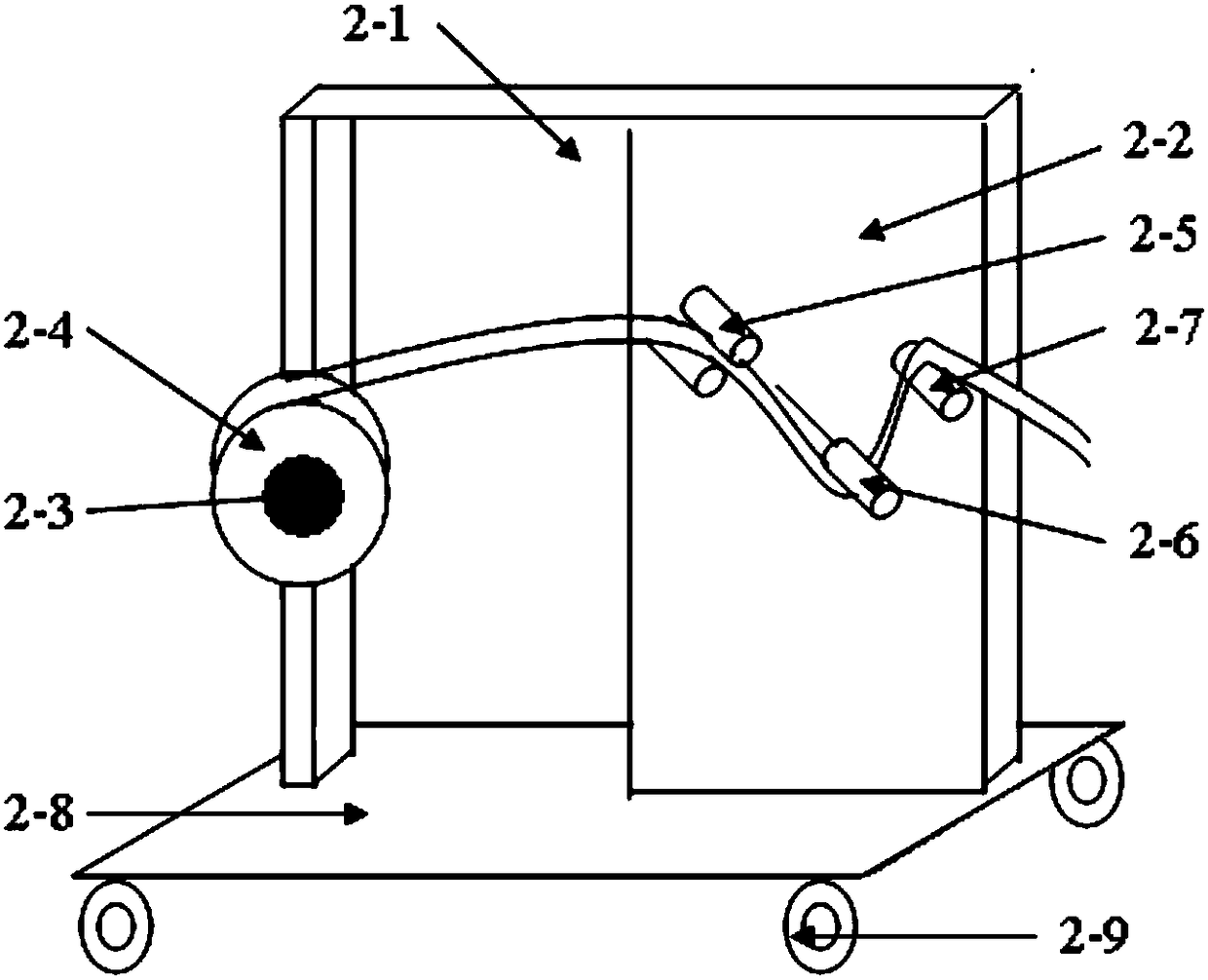

[0045] This embodiment provides a twist-free feeding system for weaving flattened weft yarns, including a weft withdrawing device, a weft feeding device, a weft receiving device, and a weft beating device; the weft returning device is arranged at the front end of the weft feeding device , the weft receiving device is arranged at the rear end of the weft feeding device, and the weft beating device is arranged at the inlet end and the outlet end of the weft receiving device.

[0046] Further, among them:

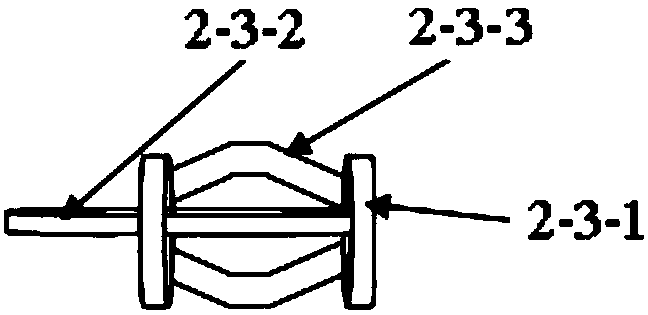

[0047] The weft unwinding device is used to maintain the width of the weft yarn, keep the surface of the weft yarn flat and adjust and control the tension of the weft yarn during the unwinding process of the flattened weft yarn;

[0048] The weft feeding device pulls the weft yarn from the weft withdrawing device to the weft receiving device in a translational manner, and cuts the weft yarn horizontally and vertically along the length direction of the weft yarn after the weft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com