Anthraquinone hydrogenation non-uniform pore channel partition nickel-based monolithic catalyst

An integrated catalyst and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of side reactions, large amount of precious metals, low catalyst selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a) Take 700 grams of active nickel oxide, 50 grams of molybdenum oxide, 250 grams of aluminum oxide and an appropriate amount of nitric acid solution and knead them into a plastic paste, extrude it into a channel with a mesh number of 200, and the area of the channel opening II and opening I A honeycomb block with a ratio of 3:1 and a height of 10 cm was dried at 100°C for 24 hours and calcined at 800°C for 4 hours to obtain a nickel-based monolithic catalyst carrier with heterogeneous channels, numbered A;

[0033] b) Immerse 4 cm from one end of the opening I of the nickel-based monolithic catalyst precursor A (area A) in a 0.5Mol / L palladium chloride solution for 5 minutes at room temperature, take it out and blow out the remaining solution in the channel, and dry it at 120°C 6 hours, calcination at 450° C. for 2 hours, repeated twice to obtain a monolithic catalyst, numbered E-1.

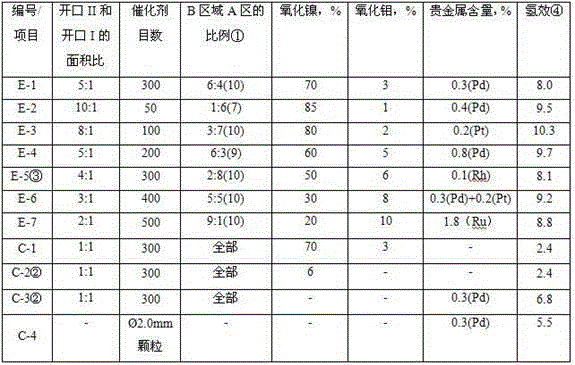

[0034] c) Carry out catalyst composition analysis and reaction performance evaluati...

Embodiment 2~7

[0036] The catalyst preparation method of each embodiment is the same as that of Example 1, except that the content of active metal components, the height of impregnated metal, the mesh number of the carrier and the cross-sectional shape of the channel are different, and the numbers of the obtained catalysts are respectively E-2~E- 7. See Table 1 for specific conditions and reaction results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com