Precision vegetable sower and rail thereof

A seeder and precision technology, applied in the directions of seeder parts, sowing, application, etc., can solve the problems of poor planting height adaptation, poor stability of track structure layout, etc., achieving good effect, convenient installation and sowing operations , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with accompanying drawing, the present invention will be further described.

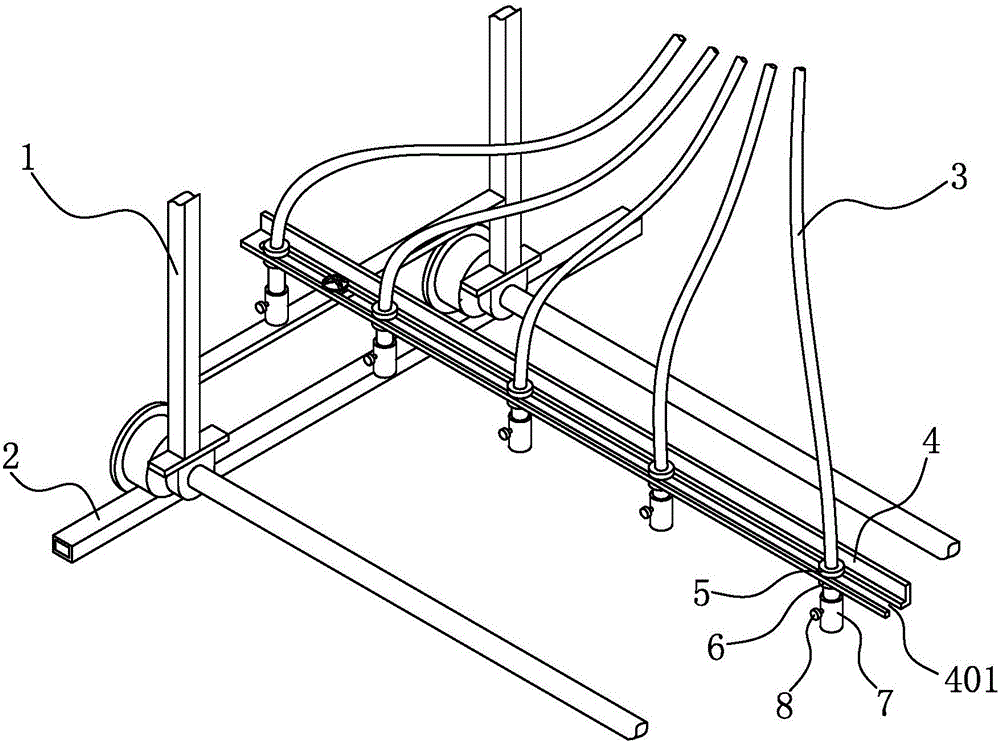

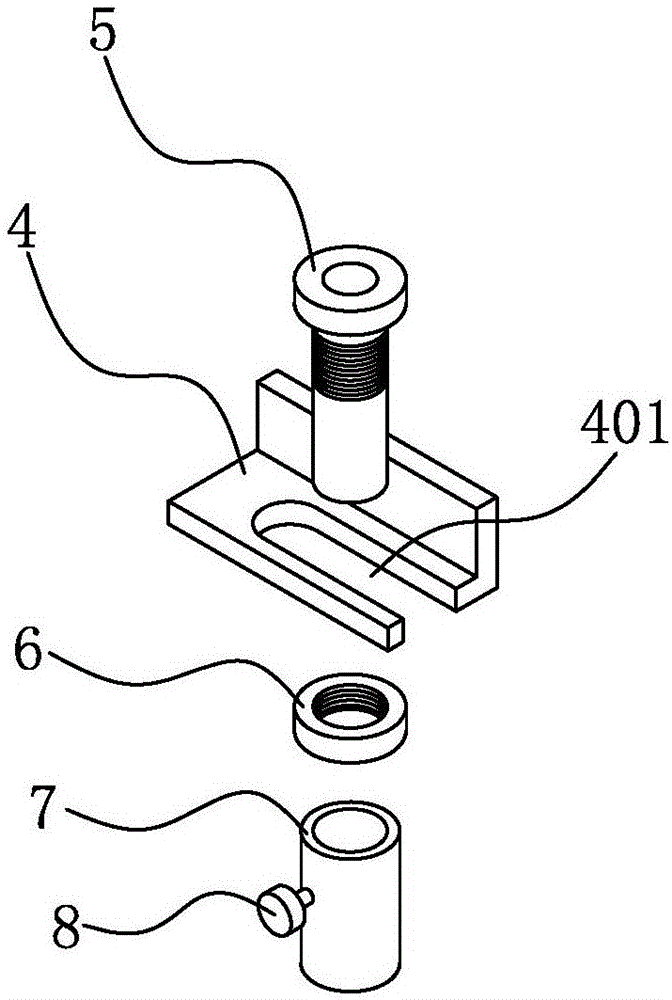

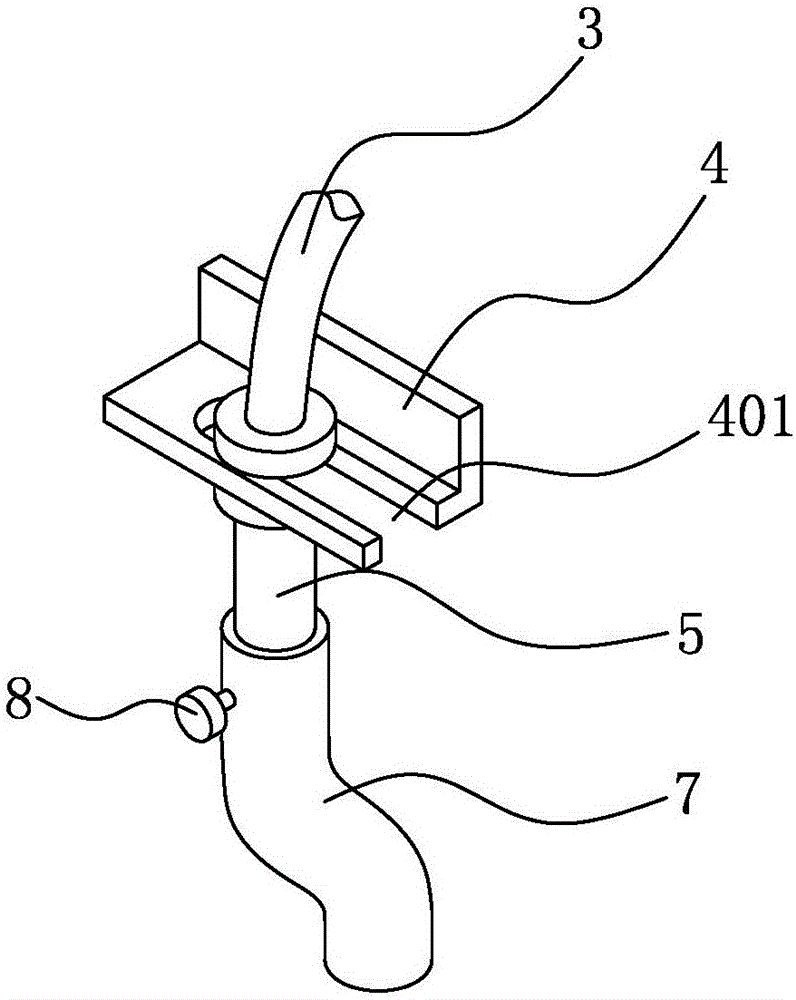

[0019] The vegetable precision seeder includes a frame 1, a seed drop assembly, a walking assembly, and a power assembly, wherein the seed drop assembly, the walking assembly, and the power assembly are all known technologies, and will not be described in detail. The above-mentioned seed-dropping assembly includes a seed-dropping box and a seed-dropping pipe 3. The walking assembly includes a driving wheel and a driven wheel. The power assembly includes a motor, a battery, and a controller. Connect the output of the motor. Such as figure 1 , figure 2 As shown, the main design of the present invention is that the bottom of the frame 1 is provided with a positioning bracket 4 that fixes the seeding position of the drop tube 3, and the positioning bracket is provided with a bar-shaped chute 401 for connecting the straight pipe cover 5, and the straight pipe The sleeve is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com