Method for manufacturing multilayer electronic component

A technology for electronic components and manufacturing methods, which is applied in the direction of multilayer capacitors, coil manufacturing, and components of fixed capacitors, etc., can solve problems such as difficulty in suppressing step differences, and achieve the effect of realizing cost reduction and shortening printing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

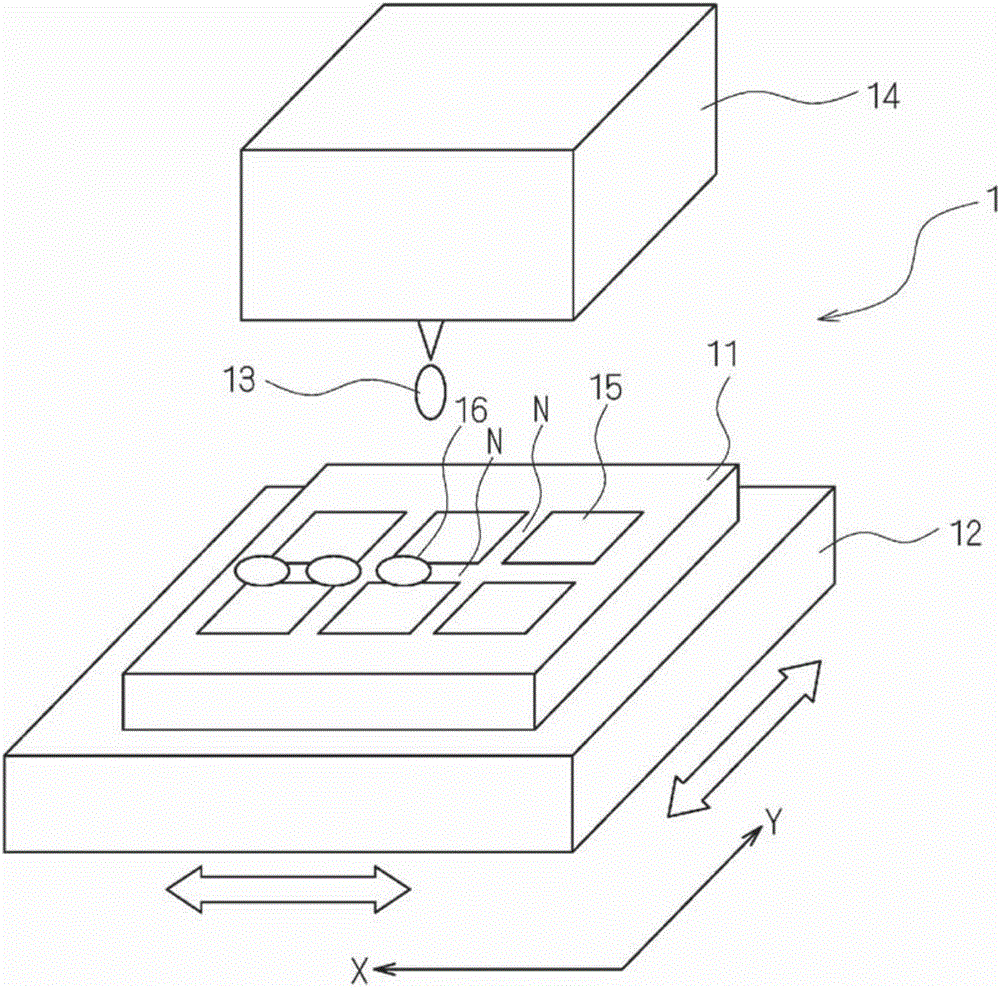

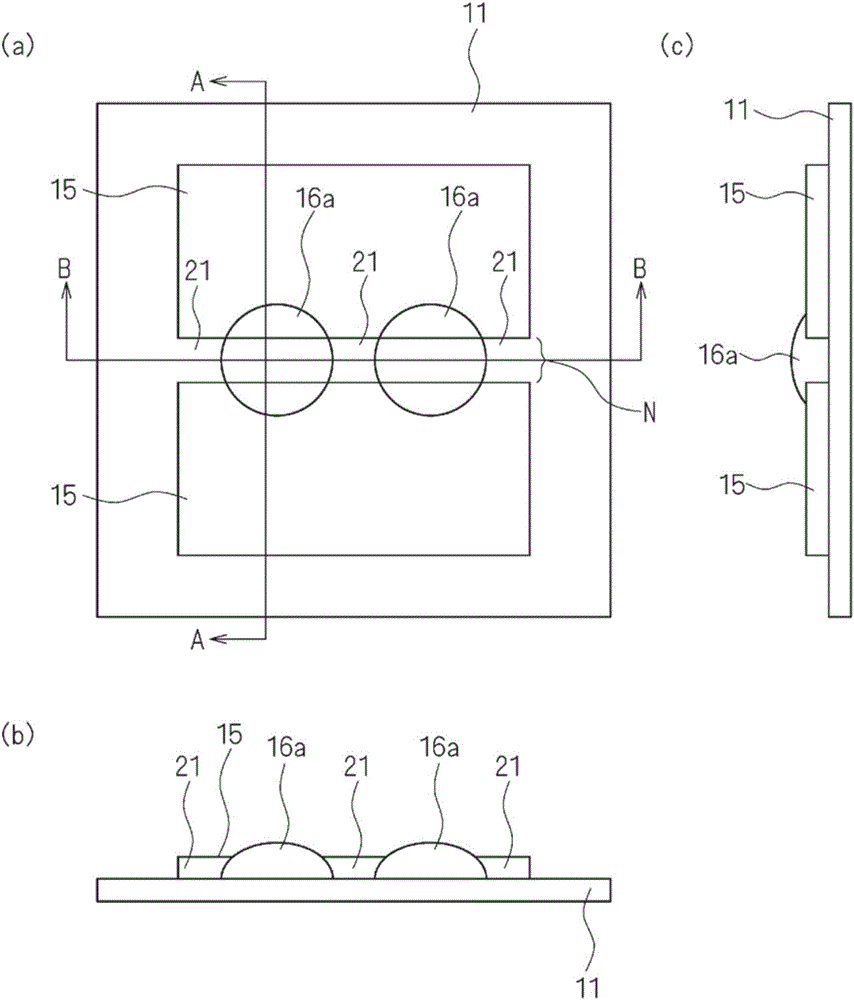

[0033] figure 1 It is a schematic diagram which shows the structure of the printing apparatus used for the manufacturing method of the laminated electronic component which concerns on Embodiment 1 of this invention. figure 1 In the example of , the insulating paste 16 is supplied to the region N between the adjacent internal electrodes 15 of the workpiece using the inkjet method as the printing method.

[0034] Such as figure 1 As shown, the printing apparatus 1 includes a stage 12 on which a workpiece 11 as an object to be printed can be mounted. The stage 12 has a mechanism capable of moving in the left-right direction (X-axis direction) and front-rear direction (Y-axis direction), and can change its positional relationship with the inkjet head 14 provided on the upper part of the workpiece 11 to drop ink droplets 13 . Therefore, ink droplets 13 can be dropped on desired positions of the workpiece 11 mounted on the stage 12 .

[0035] Of course, it is not limited to th...

Embodiment approach 2

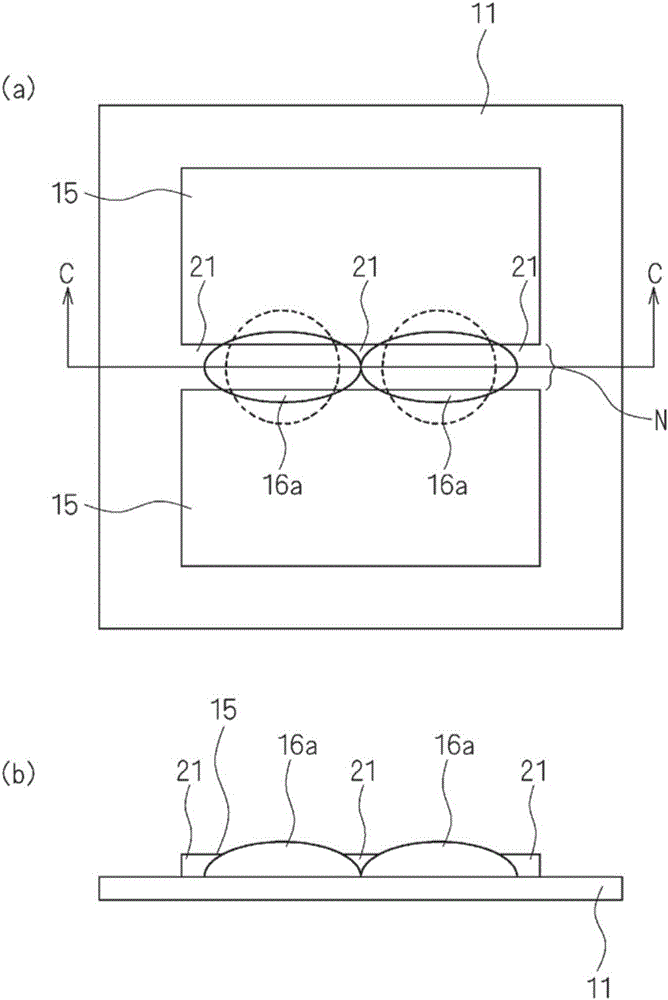

[0053] In the method of manufacturing a laminated electronic component according to Embodiment 2 of the present invention, the steps of producing one ceramic green sheet 11 are the same as those in Embodiment 1, and thus detailed description will be omitted by denoting the same reference numerals. The second embodiment differs from the first embodiment in that the position where the insulating film is formed is changed, and the ceramic green sheets 11 are laminated.

[0054] Figure 5 It is a schematic diagram showing a state where a plurality of ceramic green sheets 11 having insulating films 16a formed at the same positions are stacked in the method of manufacturing a multilayer electronic component according to Embodiment 2 of the present invention. Figure 5 (a) is a plan view showing the state where the insulating film 16a is formed on the ceramic green sheet 11, Figure 5 (b) is Figure 5 E-E sectional view of (a), Figure 5 (c) shows the state after stacking a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com