Valve for hydraulic damper

A hydraulic shock absorber and pressure technology, applied in the field of hydraulic shock absorbers, can solve the problems of displacement of structural elements, no vibration reduction effect, and inability to realize relative displacement of structural elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

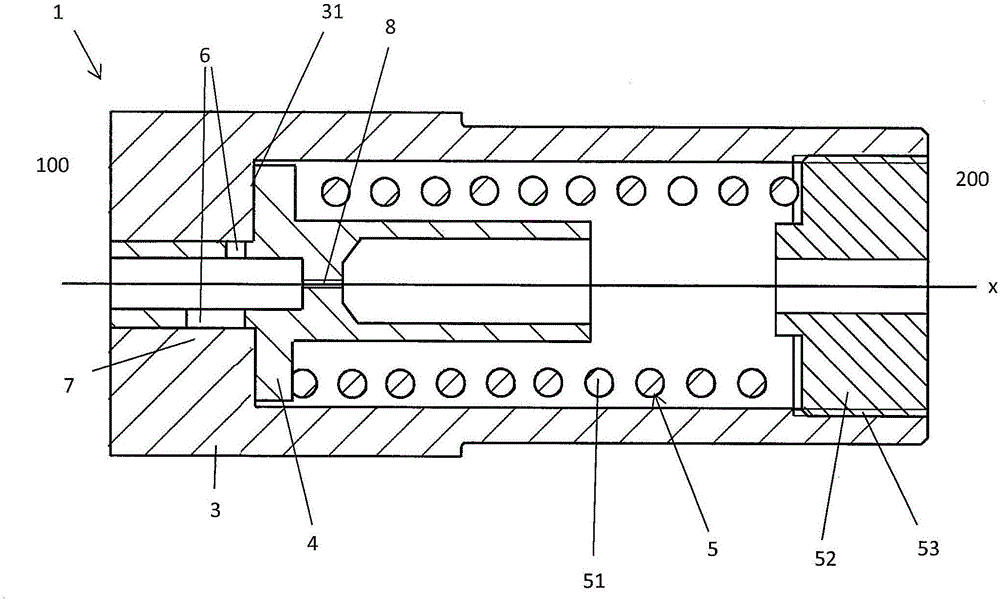

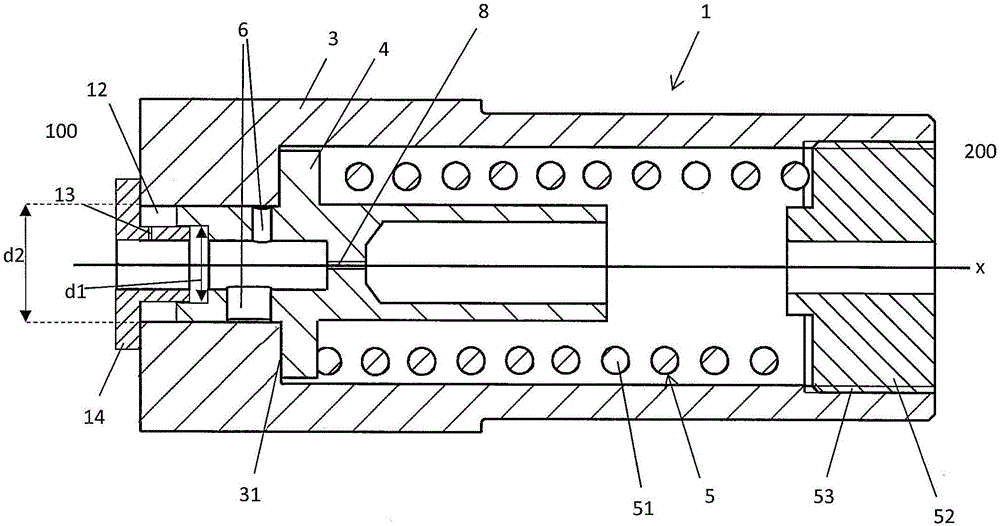

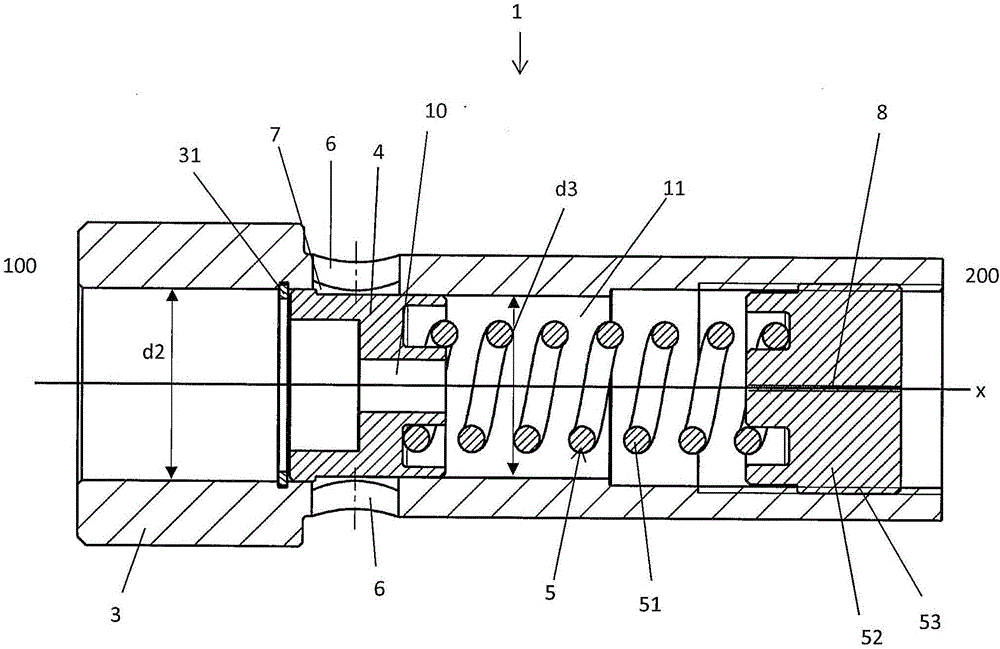

[0077] Figure 1a An exemplary embodiment of a valve 1 according to the invention is shown in a schematic sectional view. Figure 1a Valve 1 is shown in an inoperative position. The valve 1 comprises a seat element 3 and a moving element 4 . The seat element 3 has a cylinder section in the form of a hollow cylinder with a closed cylinder housing section 7 . This cylinder section of the seat element 3 holds a section of the displacement element 4 which is also configured as a hollow cylinder which has a channel 6 in its cylinder housing. The hollow cylinder section of the moving element 4 is loosely fitted into the above-mentioned hollow cylinder section of the seat element 3 . The moving element 4 and the seat element 3 guide each other on two sections, whereby the play between the moving element 4 and the seat element 3 is sufficient to allow a small amount of hydraulic fluid to penetrate between the moving element 4 and the seat element 3, thereby allowing the Lubrication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com