Forming method and array substrate of test pads

A technology for testing pads and array substrates, used in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

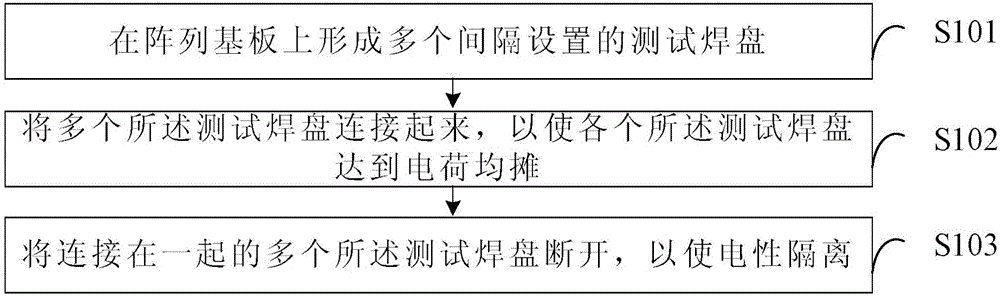

[0050] see figure 1 , is a schematic flowchart of the implementation of the method for forming the test pad provided by the embodiment of the present invention.

[0051] The method for forming the test pad includes:

[0052] In step S101, a plurality of test pads arranged at intervals are formed on the array substrate;

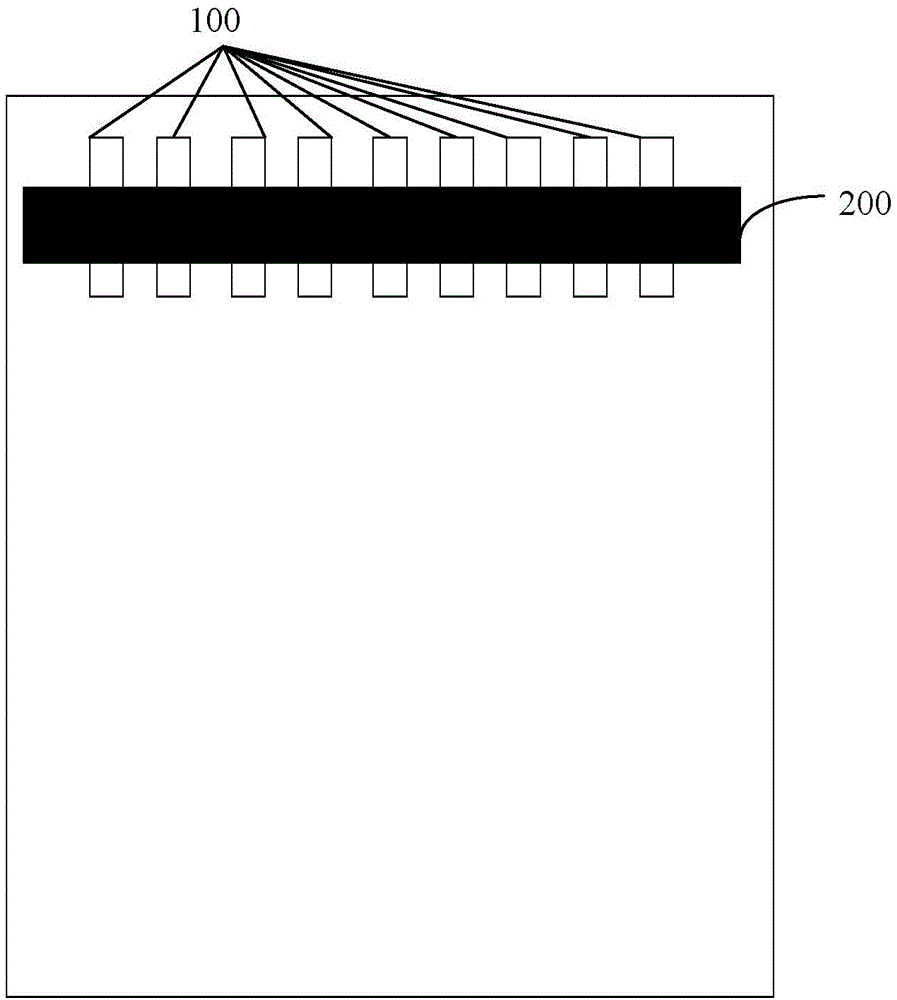

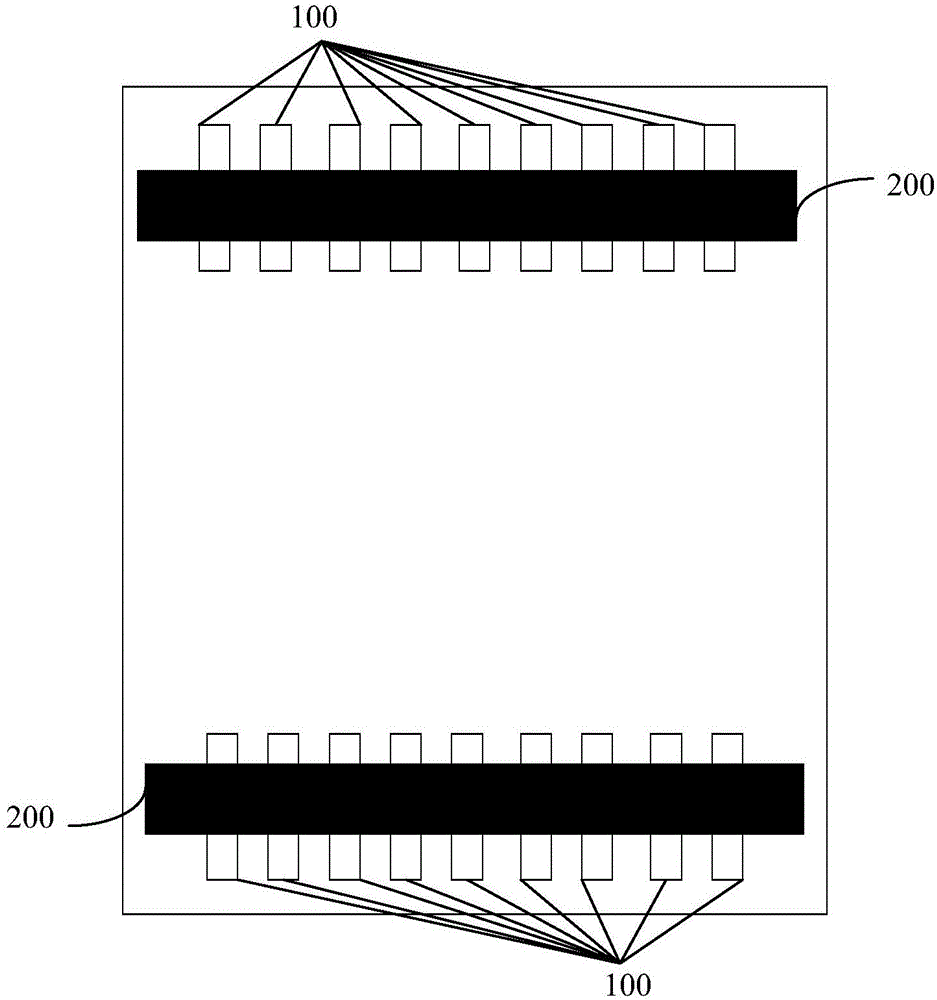

[0053] In some embodiments, for the display panel of the mobile phone, a plurality of test pads arranged at intervals are formed on the side of the array substrate. For example, a plurality of test pads arranged at intervals are formed on the upper and lower sides of the array substrate, such as image 3 shown.

[0054] In some embodiments, for a liquid crystal display panel, a plurality of test pads arranged at intervals are formed around the array substrate, such as Figure 4 shown.

[0055] In step S102, connecting a plurality of the test pads, so that each of the test pads can achieve charge sharing;

[0056] In the embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com