Luminous display with front double flat backward recessed gate controlled convex surface upper-lower ripple edge cathode structure

A technology of light-emitting display and cathode structure, which is applied in the direction of image/graphic display tube, cathode ray tube/electron beam tube, electrode device and related components, etc., and can solve the problems of high power loss of light-emitting display, gate structure burnt damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

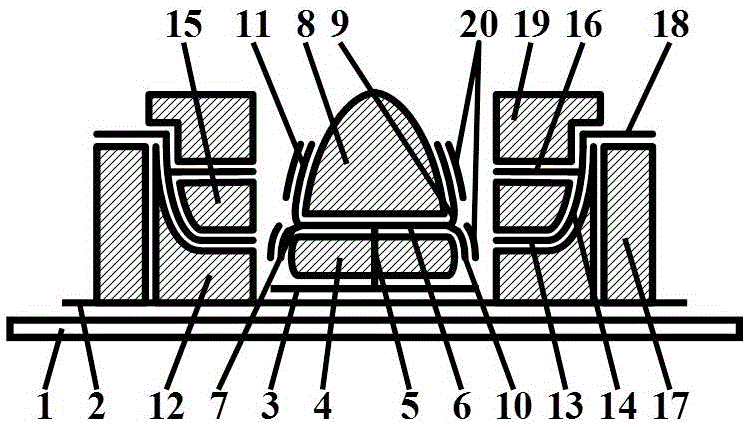

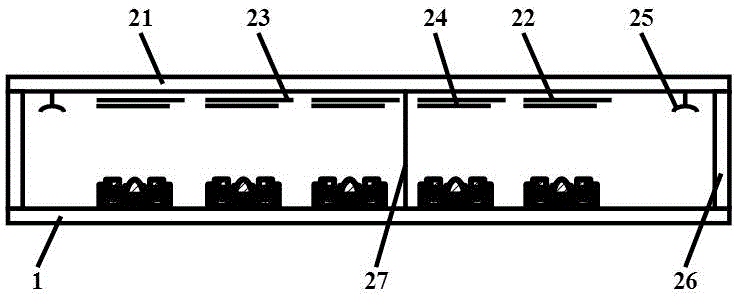

[0051] The light-emitting display with front double flat rear concave gated convex upper and lower corrugated edge cathode structure of this embodiment is shown in Fig. 1, Fig. 2 and Fig. 3. A vacuum chamber formed by a glass frame 26; an anode square film layer 22, an anode silver wiring layer 23 connected to the anode square film layer 22 and a phosphor layer prepared on the anode square film layer 22 are arranged on the upper pressure-resistant sealing flat plate 24. On the lower pressure-resistant sealing plate 1, there are front double straight and rear concave gate-controlled convex surface and upper and lower corrugated cathode structures; getter 25 and support column 27 are located in the vacuum chamber as an accessory component.

[0052] The front double straight back concave gated co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com