Metallurgical enterprise converter gas scheduling method based on knowledge

A converter gas and scheduling method technology, applied in the field of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

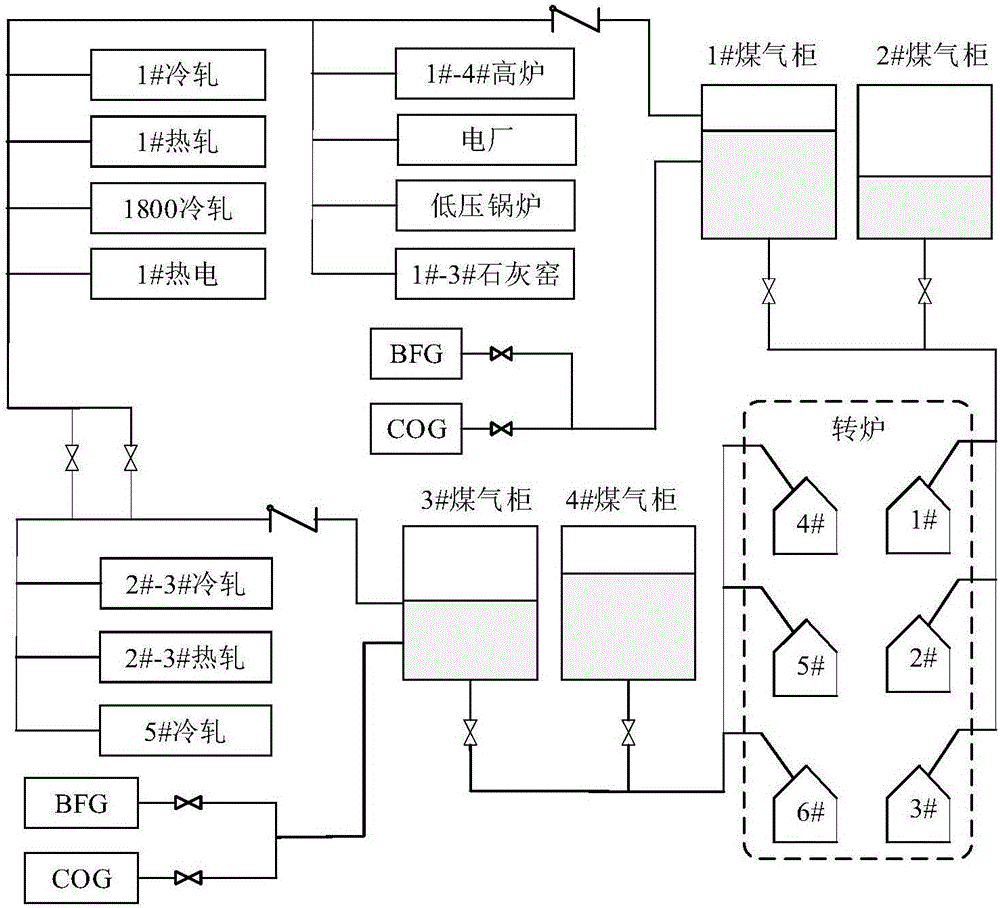

[0022] In order to better understand the technical solution of the present invention, the embodiment of the present invention will be further described by taking the converter gas system of Baosteel Iron and Steel Enterprise, which has a relatively high level of automation in China, as an example. The company's converter gas system currently has 6 converters as converter gas generating units, which generate about 200km per hour 3 There are about 30 main consumers of converter gas, mainly including blast furnaces, hot and cold rolling, lime kilns, etc.; in addition, there are generator sets, three 70-ton low-pressure boilers and one thermoelectric unit as gas regulating users ; The pipe network is equipped with four 80,000 m 3 gas cabinet. Although the on-site gas dispatchers use the real-time monitoring and counter alarm mechanism to judge the current production and consumption of the gas pipeline network through manual decision-making, and formulate the current adjustment pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com