Intelligent manufacturing industry parameter optimization method based on machine learning and industrial Internet of Things

An industrial Internet of Things and machine learning technology, applied in the field of parameter optimization in the intelligent manufacturing industry, can solve the problems of inability to adjust production methods in time, data sharing, and low efficiency of manual debugging, so as to increase flexibility, ensure quality, and reduce work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

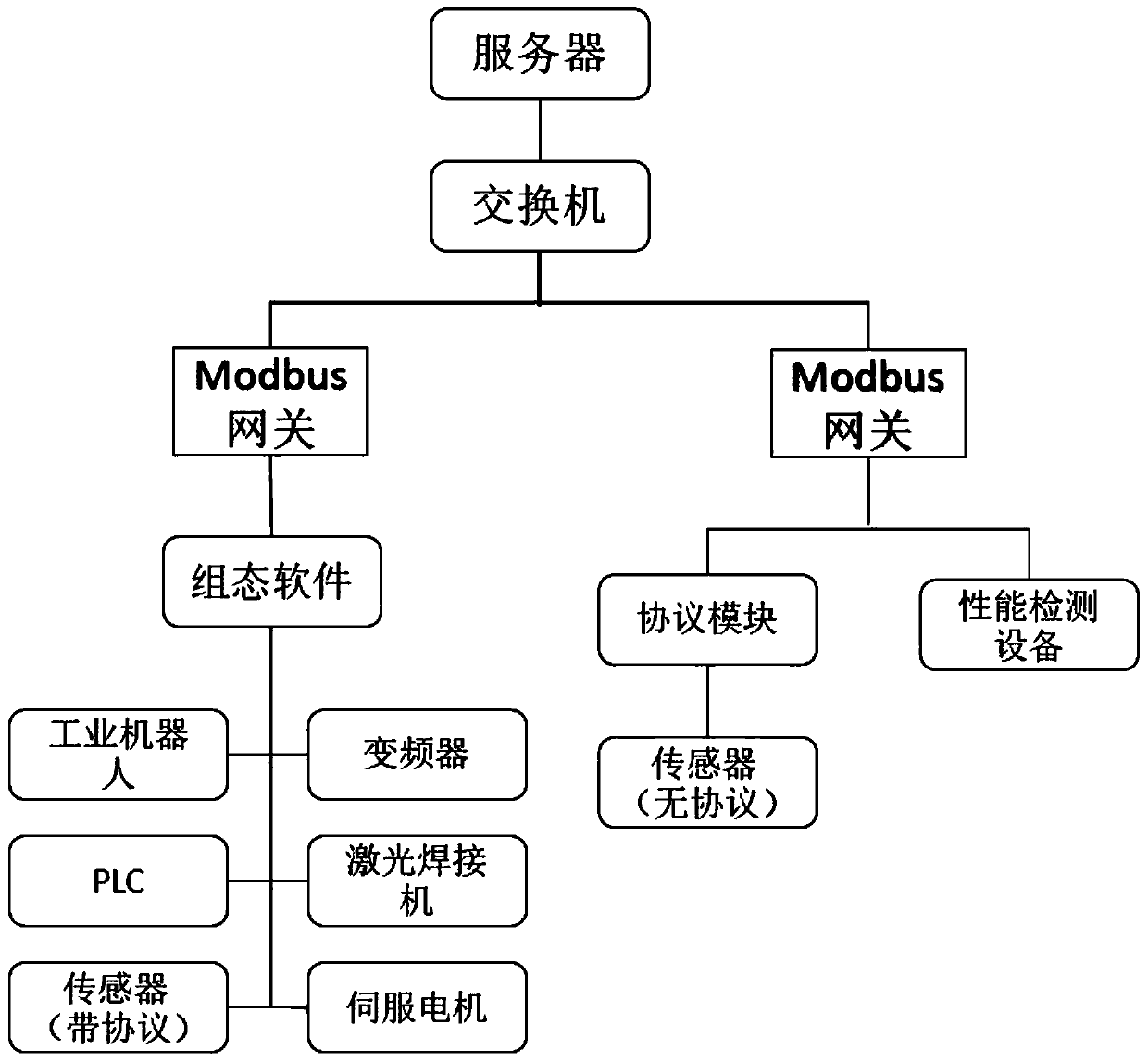

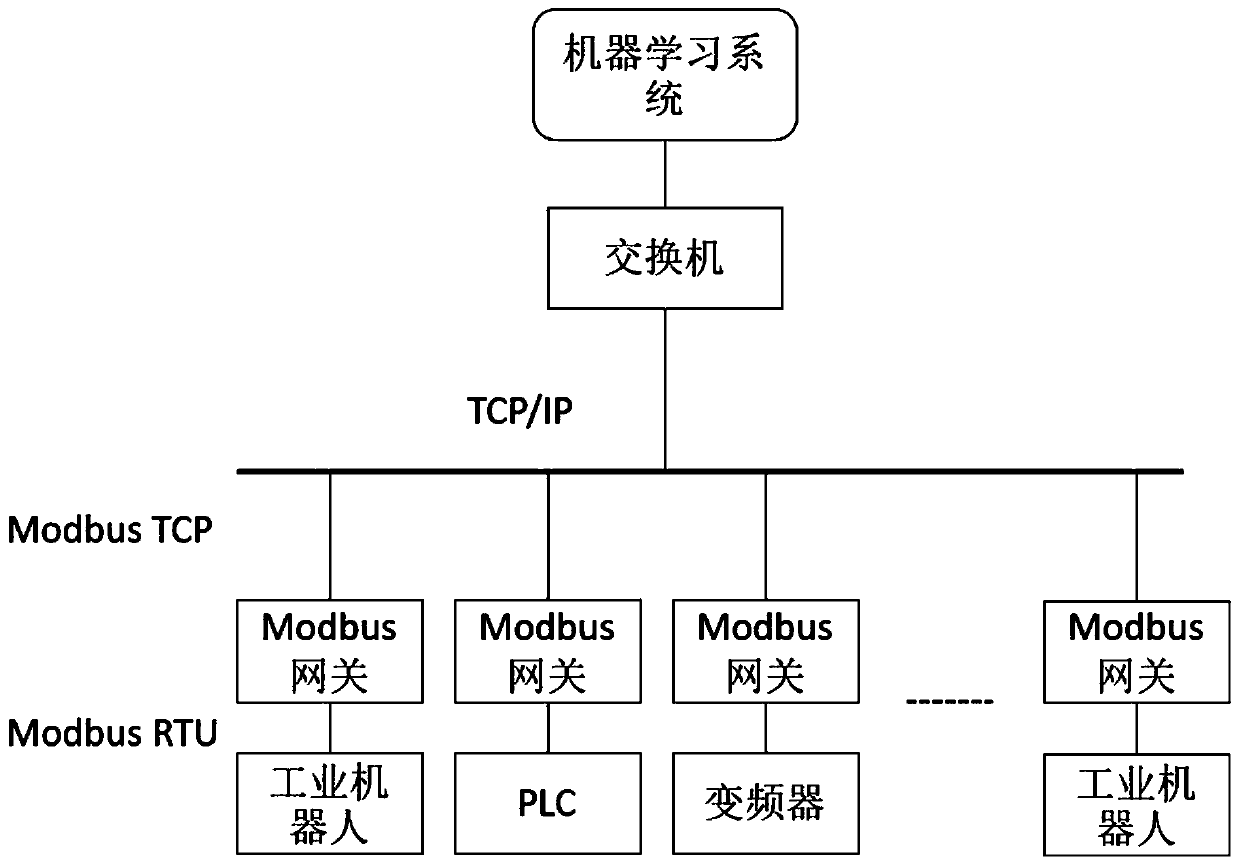

[0055] A method for optimizing parameters in the intelligent manufacturing industry based on machine learning and industrial Internet of Things, targeting the new energy battery PACK production line as a prototype, combining Figure 1 to Figure 7 As shown, including the following steps:

[0056] S1. Build an industrial Internet of Things system, connect the underlying equipment to it, import production data into the data pool, and provide data support and operating environment for the algorithm model.

[0057] S2. Analyze the process steps of the intelligent production line, build its digital production model, and correlate the collected data with the variables in the model and store them in different locations in the database.

[0058] S3. Build an association analysis model based on the process logic, import the data in the database into the model, build ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com