Optimized arrangement method of annealing production for bell-type furnace

A bell furnace and annealing technology, applied in the field of information, can solve the problems of difficulty in ensuring optimal results, low efficiency, time-consuming and labor-intensive manual production scheduling, etc., to save the time required for production scheduling, increase accuracy, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

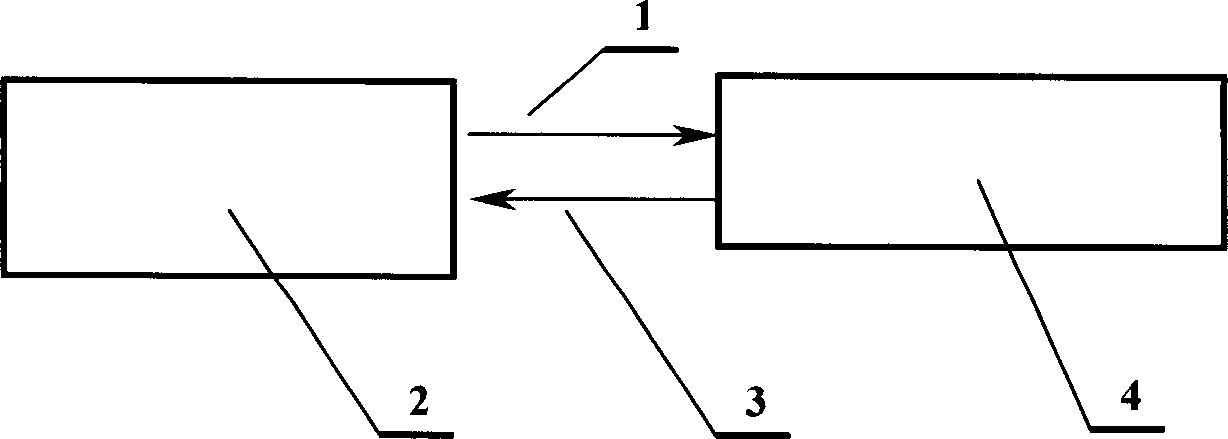

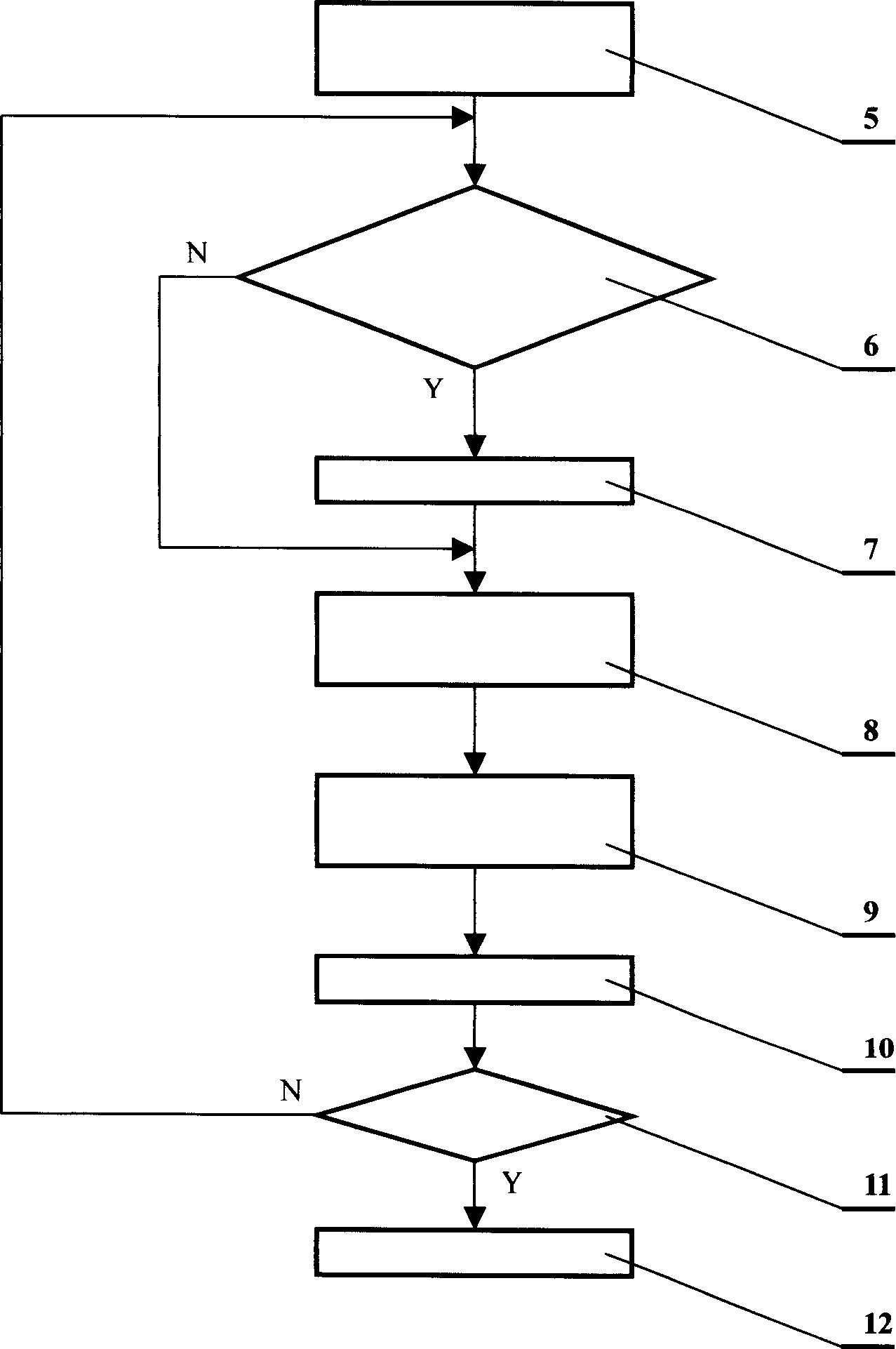

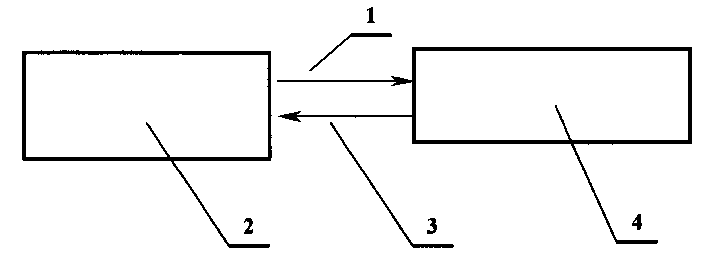

[0020] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0021] If there are 46 hearths, 23 heating mantles, 23 cooling mantles, 2 cranes, and 10 production plans to be scheduled, each different production sequence is a scheduling plan, and different scheduling plans are used for production Different production indicators will be obtained, and the purpose of production scheduling is to choose an optimal scheduling plan.

[0022] Step 1: Start the Genetic Algorithm Module

[0023] Module (2) numbers the 10 production plans to be scheduled from 1 to 10. Generate an initial population, each individual of the initial population represents a scheduling scheme, encoded with natural numbers, for example (1, 2, 3, 4, 5, 6, 7, 8, 9, 10) is an individual, representing a scheduling scheme ; and (10, 9, 8, 7, 6, 5, 4, 3, 2, 1) is another individual, representing another scheduling scheme, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com