Establishment method for ultrasonic power supply power adjustment model of ultrasonic-assisted processing acoustic system

A technology of power supply and acoustic system, applied in electrical digital data processing, instruments, geometric CAD, etc., can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific embodiments. Those skilled in the art should realize that the present invention covers all alternatives, improvements and equivalents that may be included within the scope of the claims.

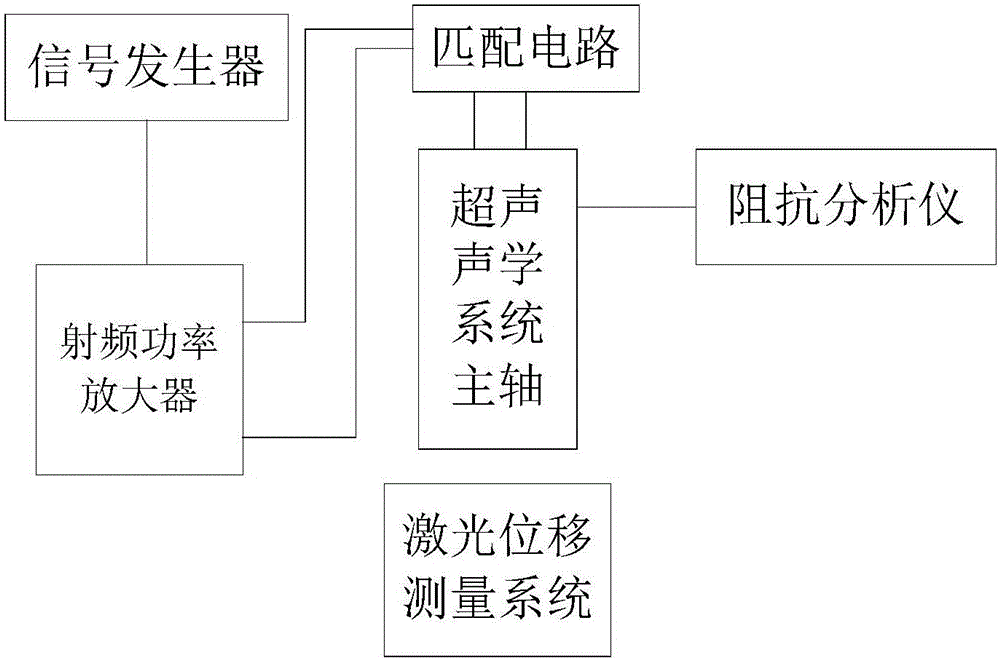

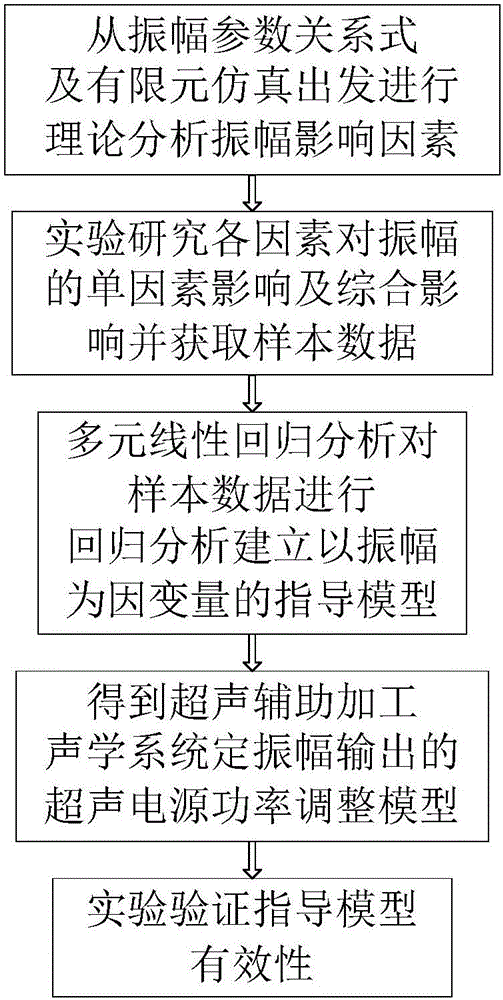

[0023] See Figure 1-2 , The method for modeling the ultrasonic power supply power adjustment model of the ultrasonic auxiliary processing acoustic system of the present invention, the specific steps are as follows:

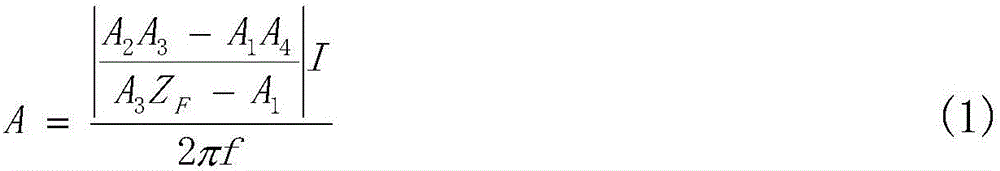

[0024] Step one, the relationship formula of the amplitude parameter is:

[0025]

[0026] Where A 1 , A 2 , A 3 , A 4 Is a constant parameter, Z F Is the load, I is the current, f is the resonance frequency, and A is the amplitude. Through the theoretical analysis of formula (1), it is found that the load and current of the acoustic system have an effect on the amplitude. Among them, the load of the acoustic system has a reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com