Integrated semi-supervised Fisher's discrimination-based industrial process fault classifying method

A Fisher discrimination and fault classification technology, applied in special data processing applications, instruments, electrical and digital data processing, etc. Facilitates automated implementation and improves the effect of limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

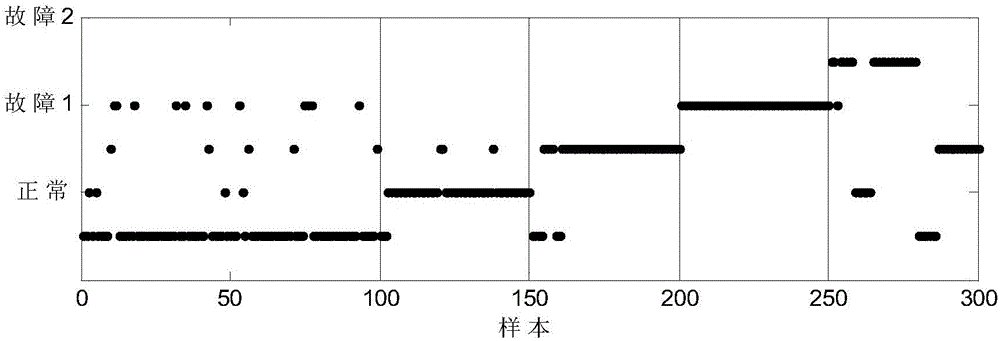

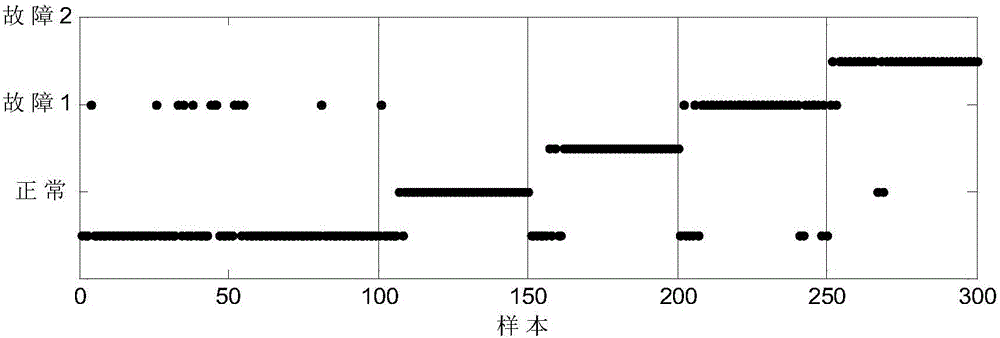

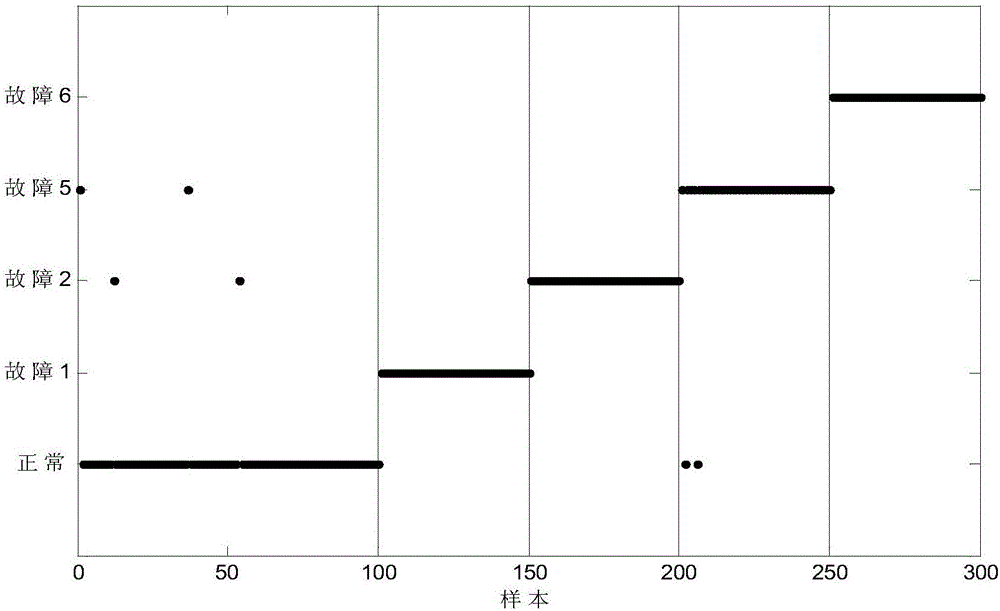

[0018] The present invention is aimed at the problem of fault classification in industrial processes. In this method, firstly, the distributed control system is used to collect data under normal working conditions and several kinds of fault data as training data sets. First, offline modeling is performed, and a large amount of unlabeled data is randomly sampled. , and form several random training subsets with all the labeled data, and then perform semi-supervised Fisher dimensionality reduction to obtain multiple Fisher discriminant matrices (composed of r Fisher discriminant vectors, r is dimensionality reduction dimension). Bayesian classification is performed on the sample data after dimensionality reduction to obtain a series of posterior probability matrices, and the posterior probability matrices of labeled data and the corresponding labels are used as training samples for the K-nearest neighbors of the metric layer fusion algorithm. Finally, during online classification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com