Head-up display laminated glass capable of realizing thermal insulation function

A technology of laminated glass and head-up display, applied in the field of head-up display, can solve the problems of affecting sight, poor heat insulation effect, high cost, and achieve the effect of clear image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

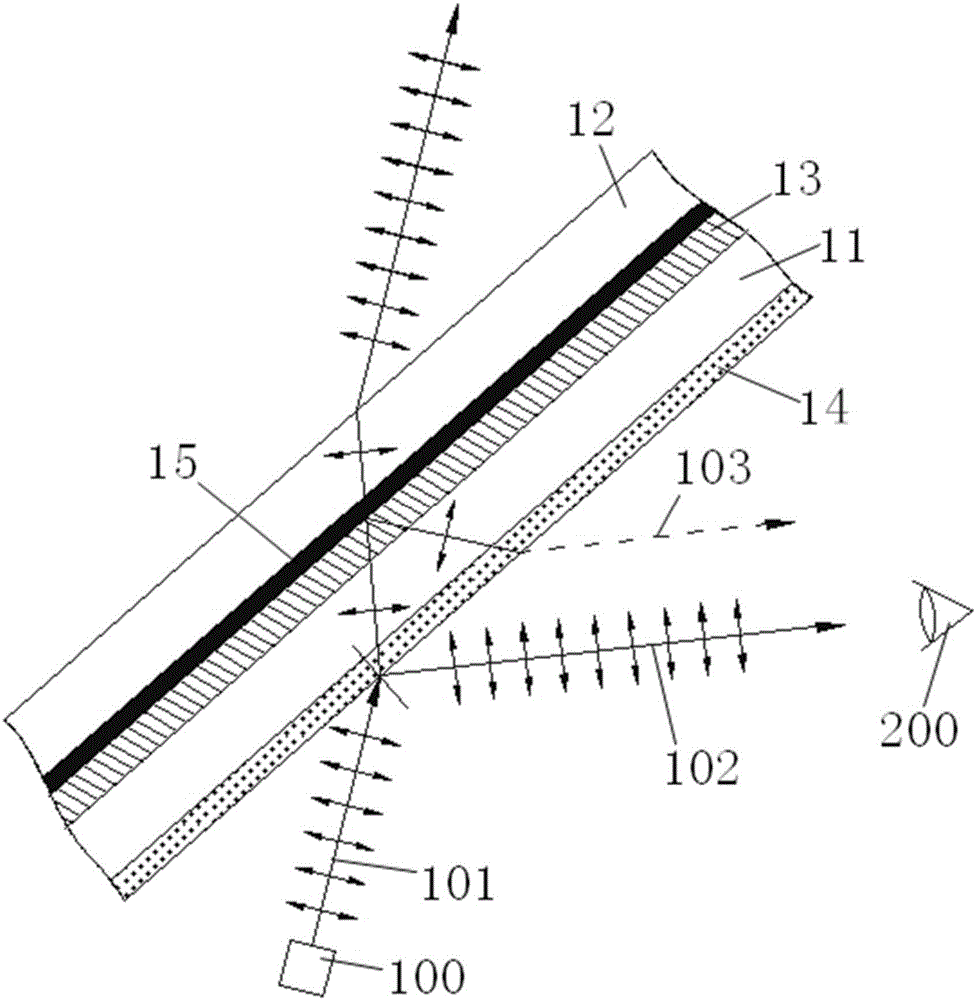

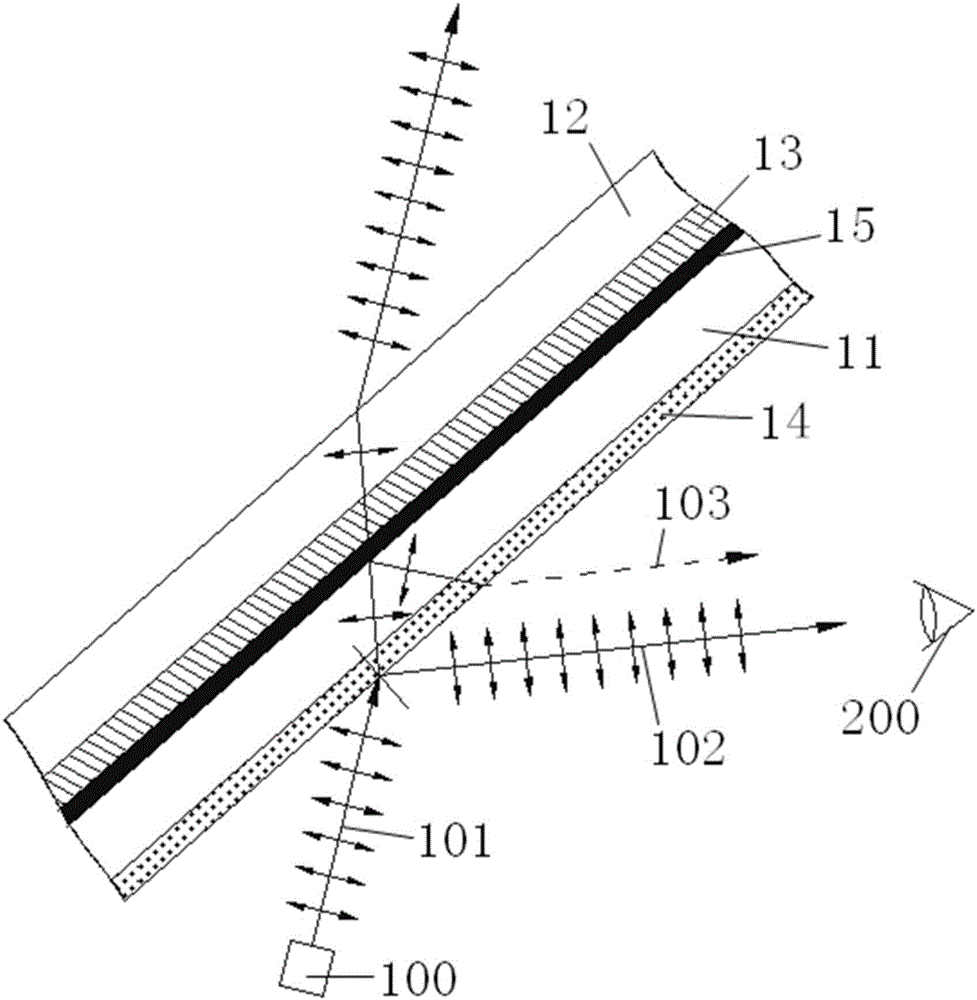

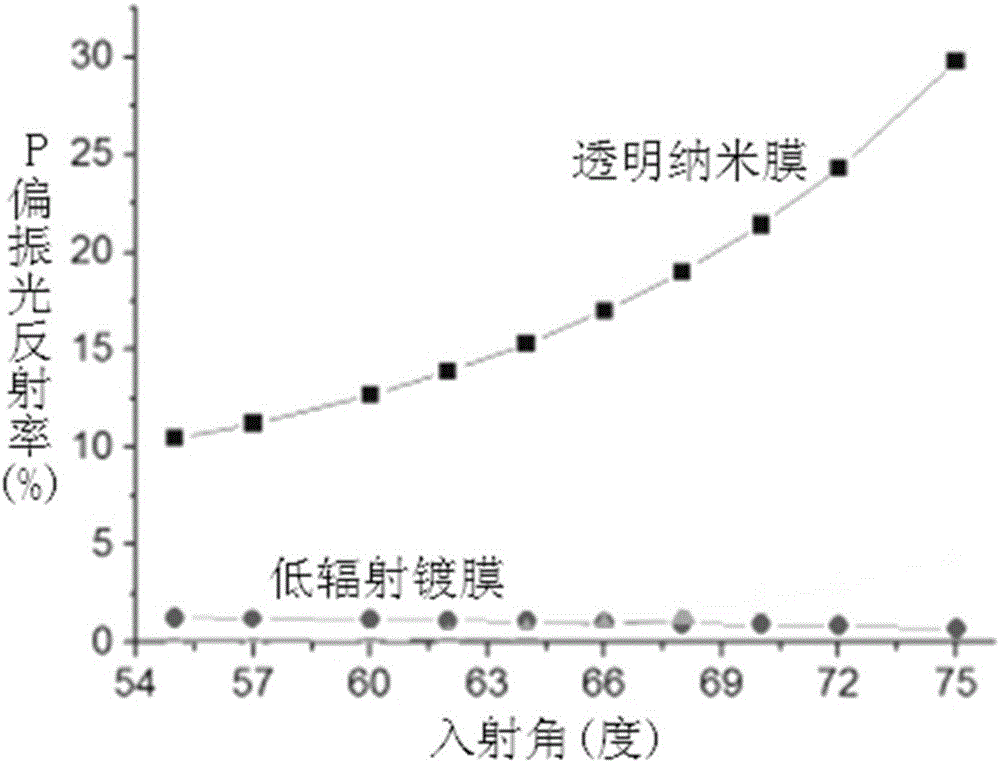

[0074] Soda lime silicate float glass with a thickness of 2.1mm produced by Fuyao Group is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for coating deposition. Two pieces The transparent nano-film and the low-emissivity (Low-E) coating including two silver layers are respectively deposited on the glass substrate. After the deposition is completed, the two glass substrates respectively deposited with the transparent nano-film and the low-e coating are matched. According to the high-temperature forming process of automobile glass, a piece of PVB film with a thickness of 0.76 mm is sandwiched in the middle, and the laminated glass plate of the present invention is made through the initial pressure and high-pressure process of the combined sheet and the installation of accessories in other processes.

[0075] Table 1: Structure and performance of laminated glass of Examples 1-2 and Comparative Examples 1-2

[007...

Embodiment 3~5

[0080] Soda lime silicate float glass with a thickness of 1.6mm produced by Fuyao Group is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for coating deposition. The transparent nano film and the low-emissivity coating in Table 2 are respectively deposited on the two surfaces of the glass substrate of mm. After the deposition is completed, it is matched with a glass substrate of 2.1 mm. A piece of PVB film with a thickness of 0.76 millimeters is installed to make the laminated glass plate of the present invention through initial pressure and high-pressure process of lamination and accessories of other processes.

[0081] Table 2: Structure and performance of laminated glass of Examples 3-5 and Comparative Example 3

[0082]

[0083]

[0084]As can be seen from Table 2, the film structure of Comparative Example 3 and Example 3 is completely consistent, the only difference is that the thickness of the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com