Inertia load simulation apparatus

A technology of simulating device and inertial load, applied in measurement devices, motor generator testing, instruments, etc., can solve the problems of inaccurate acceleration value, cumbersome operation, low frequency, etc. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

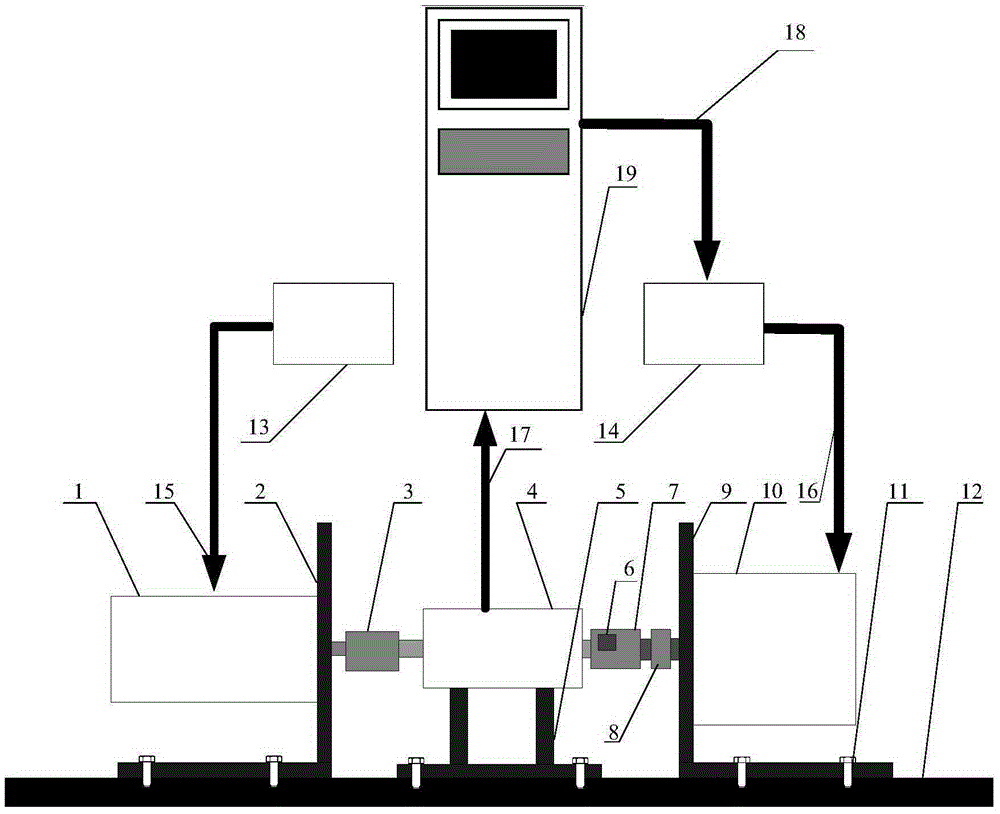

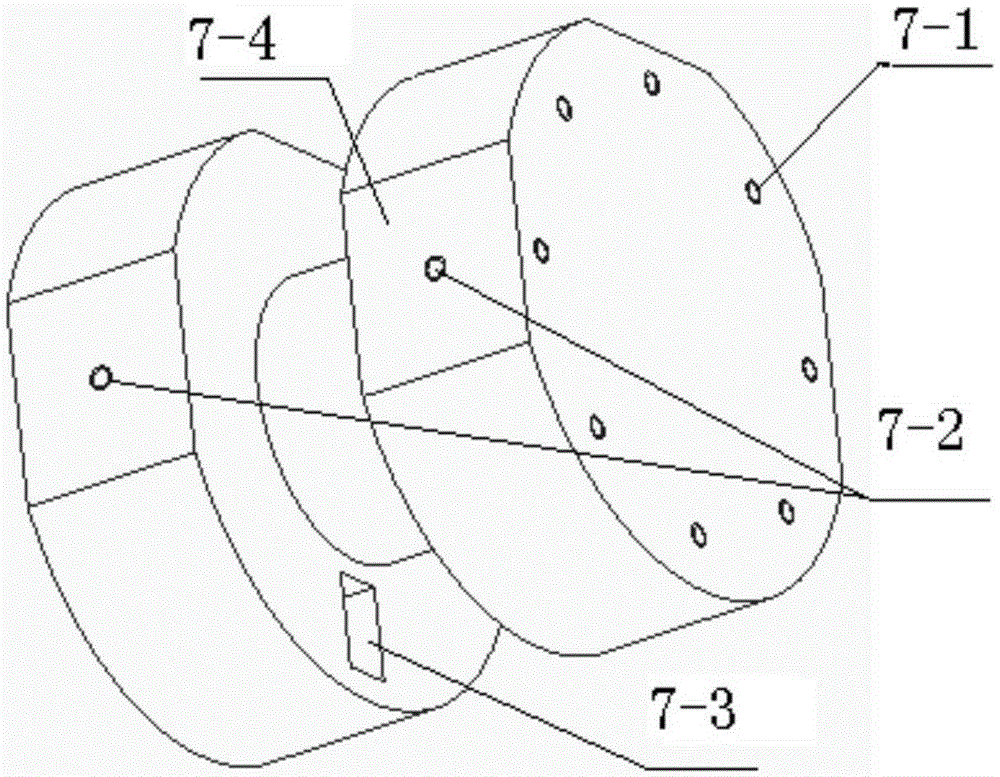

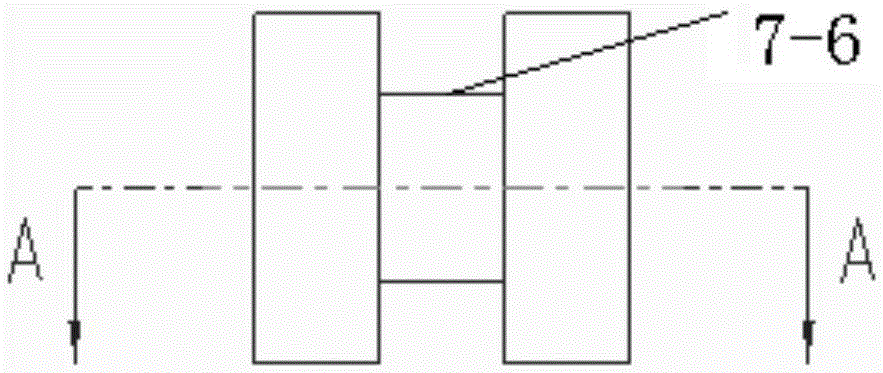

[0028] Such as figure 1 As shown, the inertial load simulation device involved in the present invention is built in the dynamic loading system of the servo motor. The dynamic loading system of the servo motor includes the motor to be tested 1, the first bracket 2, the first coupling 3, the torque sensor 4, the second Bracket 5, acceleration sensor 6, second coupling 7, electric slip ring 8, third bracket 9, loading motor 10, screw 11, ground rail 12, tested motor driver 13, loading driver 14, first signal line 15 , the second signal line 16, the third signal line 17, the fourth signal line 18, and the control cabinet 19. The first coupling 3, the torque sensor 4, the second bracket 5, the acceleration sensor 6, the second coupling 7, the electric slip ring 8, the third bracket 9, and the loading motor 10 form an inertial load loading device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com