Test apparatus for simulating stratum uplift in grouting process and test method of test apparatus

A test device and grouting technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the volume change of the formation cannot be measured, and the grouting process cannot be simulated, and the assembly and operation are convenient and fast, the sealing effect is good, and the overall The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

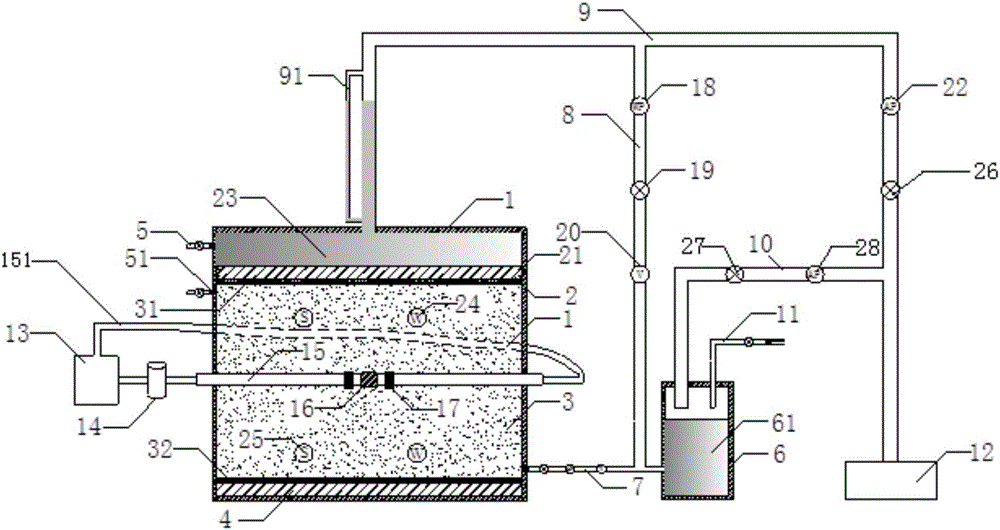

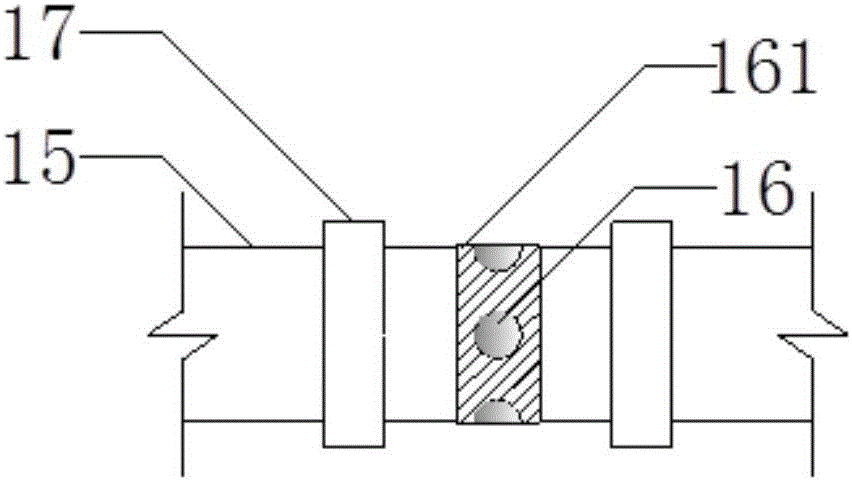

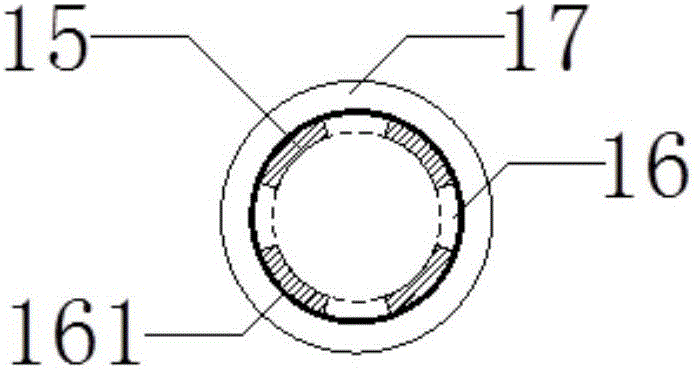

[0037] Such as figure 1 As shown, the test device for simulating formation uplift in the grouting process includes a test chamber 1, which is arranged in the test chamber 1 and divides the inner cavity of the test chamber 1 into independent soil layer loading chambers and pressurized water chambers. The pressure plate 2 of the cavity, the water intake control system and the high-pressure air conditioning system connected with the pressurized water cavity, the test soil layer 3 filled in the soil layer loading cavity, the grouting unit buried in the test soil layer 3 and The grout control system connected with the grouting unit, the soil layer loading chamber communicates with the water inlet control system through the soil layer water inlet pipe 7, and an earth pressure gauge 25 and a pore water pressure gauge 24 are buried in the test soil layer 3 . An earth pressure gauge 25 and a pore water pressure gauge 24 are set in the test soil layer 3 for measuring the changes in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com