A Method for Measuring Thermal Conductivity of Lightweight Aggregate

A thermal conductivity, lightweight aggregate technology, applied in the intersection of building materials and meso-mechanics, can solve the problem of difficult to measure the thermal conductivity of lightweight aggregates, and achieve the effect of reducing the possibility of errors and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

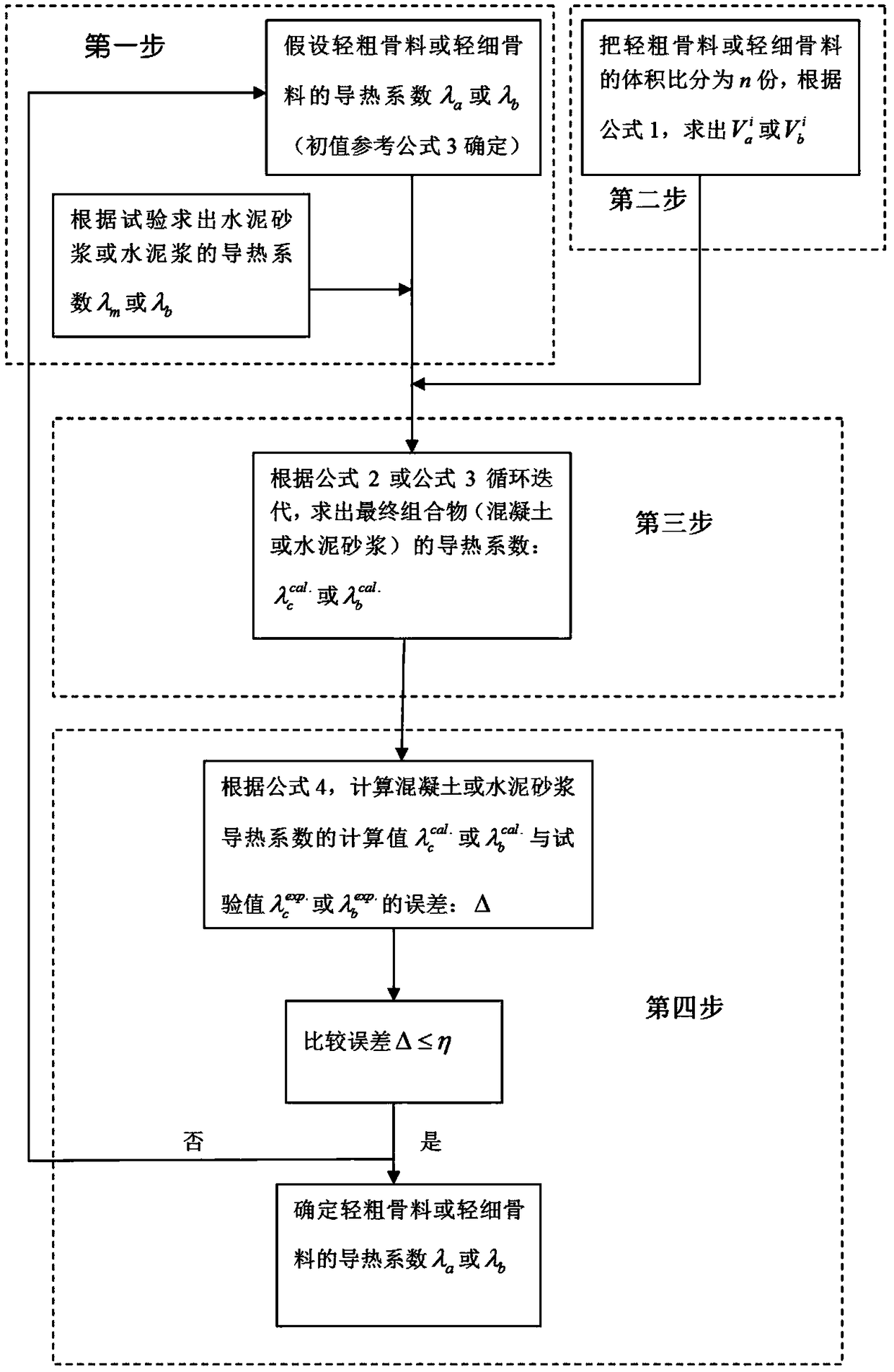

AI Technical Summary

Problems solved by technology

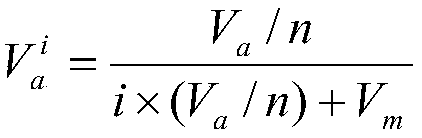

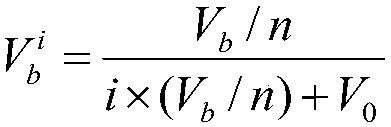

Method used

Image

Examples

Embodiment 1

[0095] The composition is cement mortar with a bulk density of 792kg / m 3 Determination of thermal conductivity of shale pottery sands.

[0096] Preparation of raw materials:

[0097]Fine aggregate: shale ceramsite, particle size 0-3mm, bulk density 792kg / m 3 .

[0098] Cement: Ordinary Portland cement with strength grade 42.5, relative density 3.1, specific surface area 3590cm 2 / g.

[0099] A method for measuring thermal conductivity of lightweight fine aggregate, the steps of which are:

[0100] 1) Prepare test pieces and conduct tests to determine thermal conductivity

[0101] (a) Determine the mix ratio: when the water-cement ratio is 0.35, 0.45, 0.55, the following table determines the mix ratio of each component material of cement mortar (Table 1). In addition, when the volume ratio of light and fine aggregate is 0, it means cement slurry and will not be listed separately.

[0102] Table 1. Mixing ratio of cement slurry and cement mortar

[0103]

[0104] (b) ...

Embodiment 2

[0135] The bulk density is 877kg / m 3 Determination of thermal conductivity of shale ceramsite.

[0136] Preparation of raw materials:

[0137] Light and coarse aggregate: particle size 4-10mm, bulk density 877kg / m 3 , apparent dry density ρ a =1662kg / m 3 .

[0138] Cement: Ordinary Portland cement with strength grade 42.5, relative density 3.1, specific surface area 3590cm 2 / g.

[0139] Fine aggregate: river sand, bulk density 1539kg / m 3 .

[0140] A method for measuring the thermal conductivity of lightweight aggregates, the steps of which are:

[0141] Table 5. Mixing ratio of cement mortar and concrete

[0142]

[0143] 1) Preparation of specimens and mechanical tests to determine mechanical parameters

[0144] (a) Determining the mix ratio: when the volume ratio of the light-coarse aggregate is =23.2%, the above table determines the mix ratio of each component material of the concrete (Table 5). In addition, when the volume ratio of light-to-coarse aggregate...

Embodiment 3

[0155] The bulk density is 785kg / m 3 Determination of thermal conductivity of shale ceramsite.

[0156] Preparation of raw materials:

[0157] Lightweight aggregate: particle size 4-10mm, bulk density 785kg / m 3 , apparent dry density ρ a =1533kg / m 3 .

[0158] Cement: Ordinary Portland cement with strength grade 42.5, relative density 3.1, specific surface area 3590cm 2 / g.

[0159]Fine aggregate: river sand, bulk density 1539kg / m 3 .

[0160] A method for measuring the thermal conductivity of lightweight aggregates, the steps of which are:

[0161] 1) Preparation of specimens and mechanical tests to determine mechanical parameters

[0162] (a) Determine the mix ratio: when the volume ratio of lightweight aggregate is V a =44.8%, the following table determines the mix ratio of each component material of concrete (Table 7). In addition, when the volume ratio of lightweight aggregate is 0, it means cement mortar and will not be listed separately.

[0163] Table 7. Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com