Viscosity detection sensor based on double piezoelectric coupling

A detection sensor, dual piezoelectric technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as stability and reading accuracy limitations, very strict environmental conditions, and timing errors in experimental results, to achieve a reasonable layout, The effect of light weight and enhanced anti-vibration function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The present invention will be further described below in conjunction with accompanying drawing:

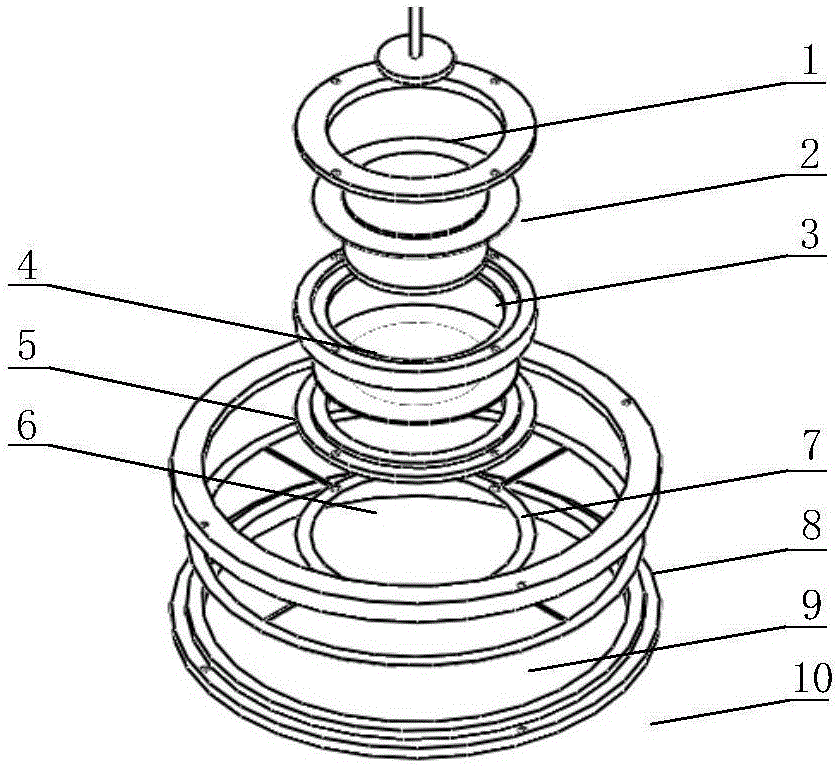

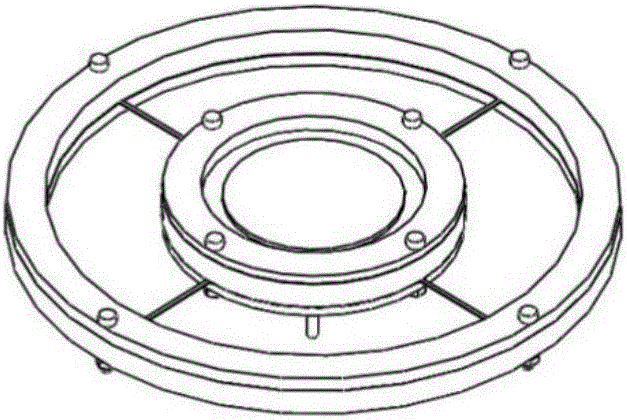

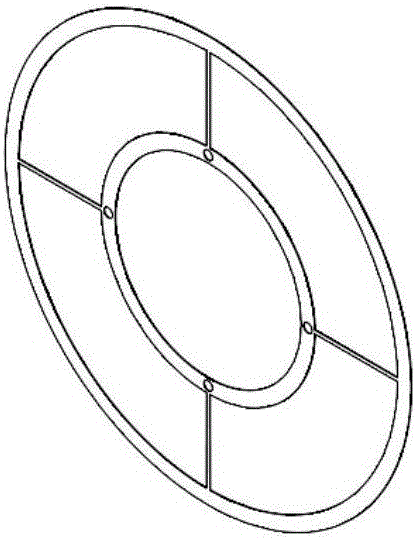

[0014] As shown in the figure, among them, 1 is a microprobe, 2 is a piezoelectric quartz crystal fastening upper gland, 3 is an output unit, 4 is a mechanical vibration conduction column, 5 is a piezoelectric quartz crystal fastening support seat, and 6 is a Feedback unit, 7 is piezoelectric quartz crystal fastening lower gland, 8 is installation, support and positioning gland, 9 is elastic member, 10 is installation, support and positioning base.

[0015] The micro-probe 1 is glued to the surface of the output unit 3, and is used for transmitting and feeding back the signal of the change rule of viscosity of the measured sample; The electric quartz crystal fastening upper gland 2, the piezoelectric quartz crystal fastening support base 5 and the piezoelectric quartz crystal fastening lower gland 7 are all provided with fixing holes for screws to pass through, and the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com