Diagonal axis type dynamic weight measurement system and diagonal axis type dynamic weight measurement method

A diagonal axis and dynamic technology, applied in the direction of measuring devices, weighing equipment testing/calibration, instruments, etc., can solve the problems of relatively high accuracy of weighing measurement and the difficulty of dynamic weighing system to meet the requirements, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

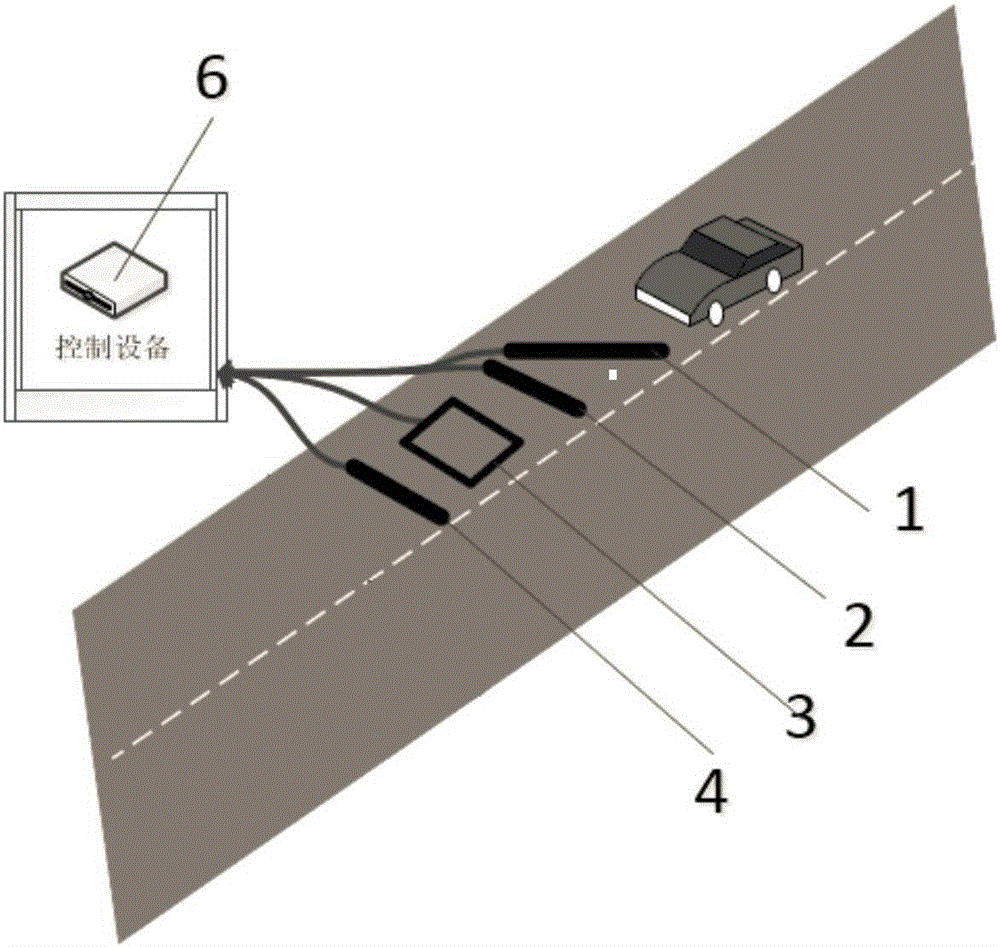

[0021] see figure 1 It shows that the present invention relates to a dynamic weighing system, especially a 1-composition Z-type dynamic weighing system with two parallel input-speed piezoelectric axes 2, output-speed piezoelectric axes 4 and diagonal piezoelectric axes 1 the embodiment. The diagonal piezoelectric axis dynamic weighing system of the present invention is composed of an input-speed piezoelectric axis 2 and an output-speed piezoelectric axis 4 , a diagonal piezoelectric axis 1 and a control device 6 . The system includes the diagonal piezoelectric axis 1, the input speed piezoelectric axis 2, the output speed piezoelectric axis 4 and the diagonal piezoelectric axis 1, the input speed piezoelectric axis 2 and the output speed piezoelectric axis arranged in the weighing area. 4 connected to the control device 6, the control device 6 calculates and displays the weight of the truck according to the electrical signals output by the diagonal piezoelectric shaft 1, the ...

Embodiment 2

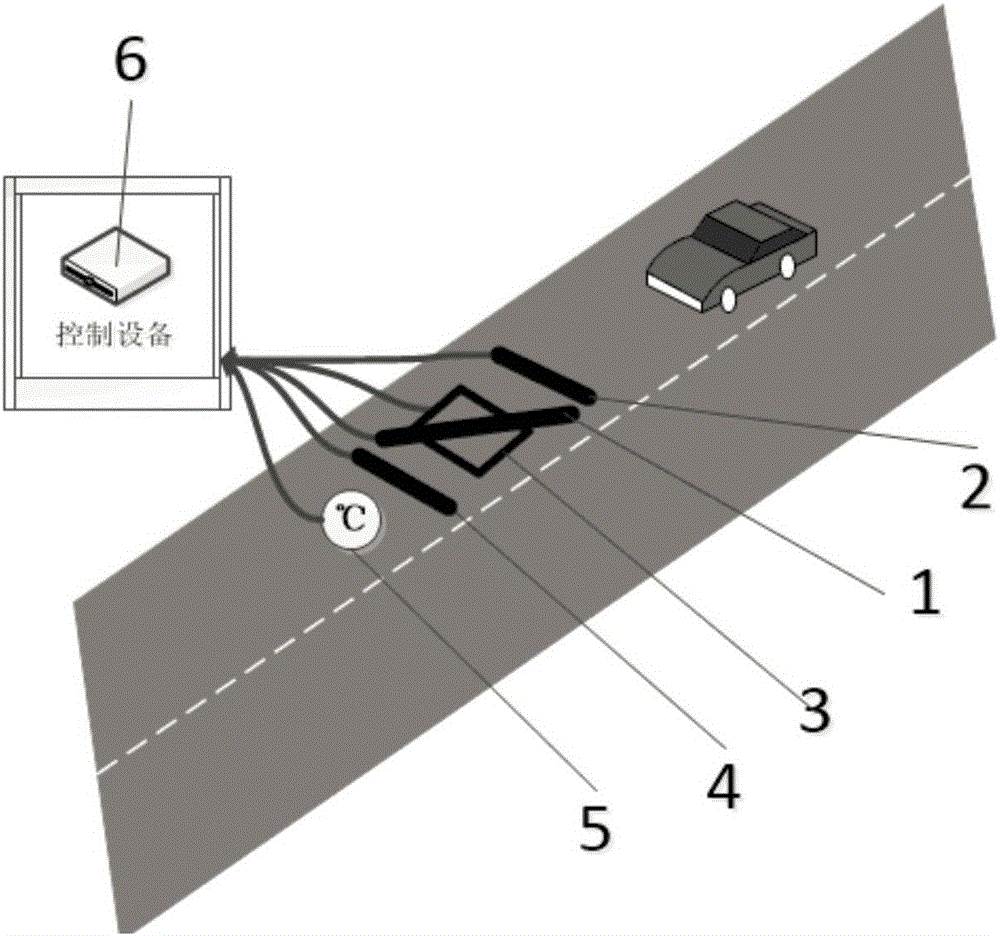

[0030] see figure 2 The main components and assembly position relationship of a kind of diagonal axis type (Z type) dynamic weighing system in this embodiment are shown. In this embodiment, a temperature sensor 5 is added in Embodiment 1. , with a diagonal piezoelectric axis 1, an input speed piezoelectric axis 2, a ground sense coil 3, an output speed piezoelectric axis 4, a temperature sensor 5, and a control device 6, wherein: the system includes a diagonal Piezoelectric axis 1, input speed piezoelectric axis 2, ground sense coil 3, output speed piezoelectric axis 4 and temperature sensor 5, and control device 6 connected with input speed piezoelectric axis 2 and output speed piezoelectric axis 4, control The device 6 calculates and displays the weight of the truck according to the electrical signals output by the diagonal piezoelectric axis 1 , the input speed piezoelectric axis 2 and the output speed piezoelectric axis 4 .

[0031] In this embodiment, the diagonal piezo...

Embodiment 3

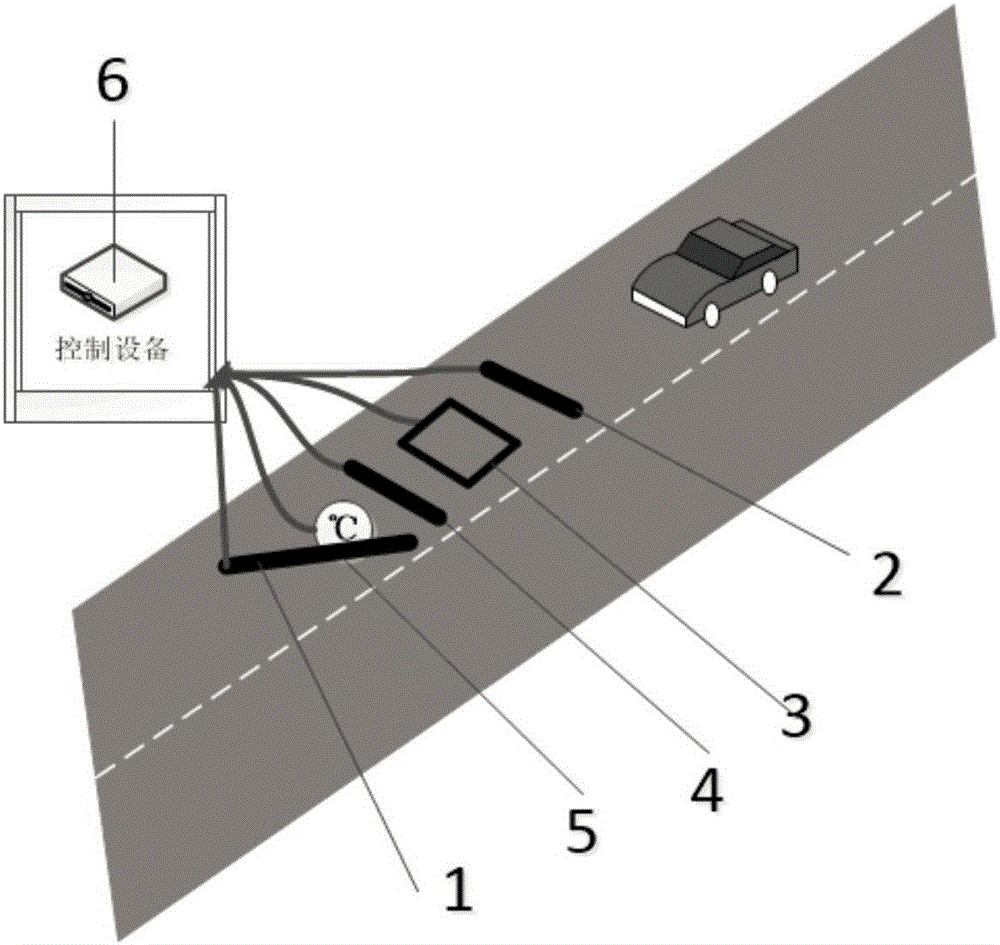

[0039] see image 3 It shows a diagonal axis type (Z type) dynamic weighing system in this embodiment, which is provided with a diagonal piezoelectric axis 1, an input speed piezoelectric axis 2, a ground sense coil 3, an output speed piezoelectric axis 4, and a temperature sensor 5. Control device 6, wherein: the system includes a diagonal piezoelectric axis 1, an input speed piezoelectric axis 2, a ground sensing coil 3, an output speed piezoelectric axis 4, and a temperature sensor 5 arranged in the weighing area, and is connected with the input The control device 6 connected to the speed piezoelectric axis 2 and the output speed piezoelectric axis 4, the control device 6 calculates and displays the load according to the electrical signals output by the diagonal piezoelectric axis 1, the input speed piezoelectric axis 2 and the output speed piezoelectric axis 4 car weight.

[0040] The present embodiment is based on embodiment 1-2. This embodiment also includes: the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com