Seal assembly in concrete drain pipe

A technology for sealing components and drainage pipes, which is applied in the direction of pipes/pipe joints/fittings, passing elements, sleeves/sockets, etc., which can solve problems such as poor stability and achieve high sealing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

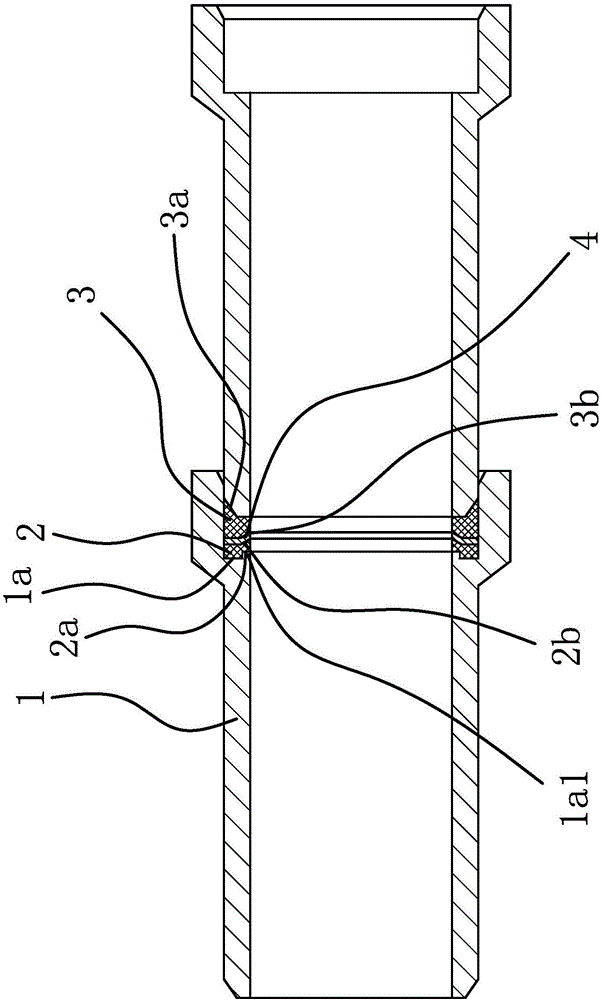

[0030] Such as figure 1 As shown, the sealing assembly in the concrete drainage pipe, the concrete drainage pipe includes a long tubular body 1, the end of the body 1 has a concave connection seat 1a, the sealing assembly is located at the end of the body 1, including a sealing ring 2 and seal ring two 3, the seal ring one 2 and seal ring two 3 are both flexible materials and have a connection structure that can make them tightly connected between the two. When two adjacent bodies 1 are connected in series, the above seal rings A 2 and a sealing ring 2 3 are tightly pressed between the two bodies 1 .

[0031] The bottom of the connection base 1a has a protruding convex edge 1a1, and the sealing ring 1 has a concave shoulder 2a matching the convex edge 1a1, and the convex edge 1a1 is embedded in the concave shoulder 2a.

[0032] The outer edge of the seal ring 2 3 has a guide edge 3a that smoothly transitions from the edge to its center, and the end of the body 1 has a guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com