Memory alloy damper and preparation method thereof

A memory alloy and memory alloy wire technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of general sound insulation and vibration reduction, improve the service life and safety of equipment, and prevent loosening. , to create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

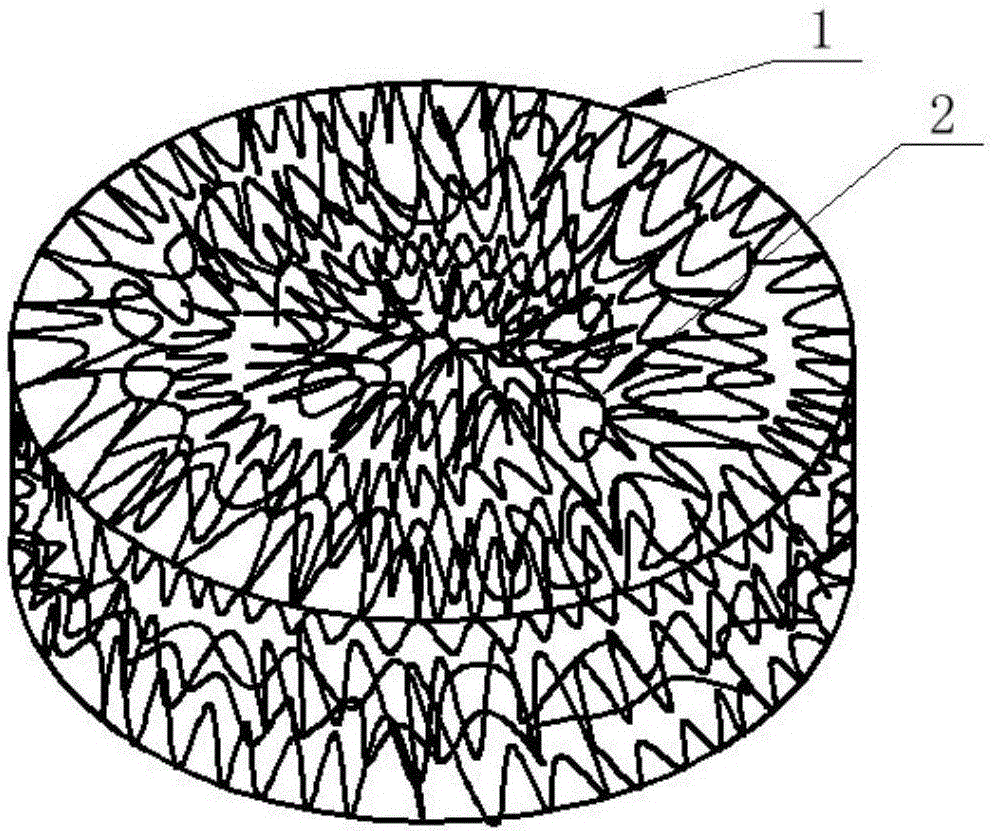

[0029] see figure 1 As shown, a memory alloy shock absorber includes a shock absorber body 1 , and the shock absorber body is a three-dimensional grid structure formed by winding at least one memory alloy wire 2 .

[0030] In this embodiment, the wire diameter of the memory alloy wire is 0.05-5 mm.

[0031] The shock absorber body is a cylindrical structure with an opening 3 in the middle, with an inner diameter of 2-800mm, an outer diameter of 4-1000mm, and a free height of 2-20mm.

[0032] A method for preparing a memory alloy shock absorber, comprising the steps of:

[0033] Step 1. Weaving the memory alloy wire into a helical spring hollowed out in the middle;

[0034] Step 2, winding the helical spring obtained in Step 1 on the mandrel, placing it in a mold, and pressing it with a compressor to obtain a semi-finished product of the shock absorber;

[0035] Step 3: The semi-finished shock absorber formed in step 2 is shaped and tempered in a heat treatment furnace to ob...

Embodiment 2

[0037] see figure 2 As shown, a memory alloy shock absorber includes a shock absorber body 1 , and the shock absorber body is a three-dimensional grid structure formed by winding at least one memory alloy wire 2 .

[0038] In this embodiment, the wire diameter of the memory alloy wire is 0.05-5 mm.

[0039] The shock absorber body is a cylindrical structure with an outer diameter of 4-1000 mm and a free height of 2-20 mm.

[0040] A method for preparing a memory alloy shock absorber, comprising the steps of:

[0041] Step 1, weaving the memory alloy wire into a helical spring;

[0042] Step 2, placing the helical spring obtained in Step 1 in a mould, and using a compressor to press and form it to obtain a semi-finished product of the shock absorber;

[0043] Step 3: The semi-finished shock absorber formed in step 2 is shaped and tempered in a heat treatment furnace to obtain a finished shock absorber.

Embodiment 3

[0045] see image 3 As shown, a memory alloy shock absorber includes a shock absorber body 1 , and the shock absorber body is a three-dimensional grid structure formed by winding at least one memory alloy wire 2 .

[0046] In this embodiment, the wire diameter of the memory alloy wire is 0.05-5 mm.

[0047] The shock absorber body is a square structure with a length of 2-1000mm, a width of 2-1000mm, and a free height of 2-1000mm.

[0048] A method for preparing a memory alloy shock absorber, comprising the steps of:

[0049] Step 1. Weaving the memory alloy wire into a square three-dimensional grid structure;

[0050] Step 2, placing the three-dimensional grid structure obtained in Step 1 in a mold, and pressing and molding with a compressor to obtain a semi-finished shock absorber;

[0051] Step 3: The semi-finished shock absorber formed in step 2 is shaped and tempered in a heat treatment furnace to obtain a finished shock absorber.

[0052] The shock absorber of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com