Multifunctional telescopic inverted arch trestle

A telescopic and multi-functional technology, applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problems of low construction efficiency, repeated procedures, cumbersome operation, etc., to reduce labor intensity, ensure construction quality, and save construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

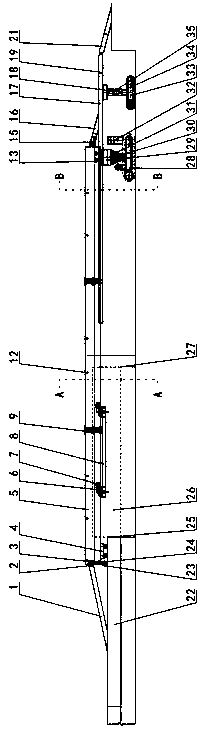

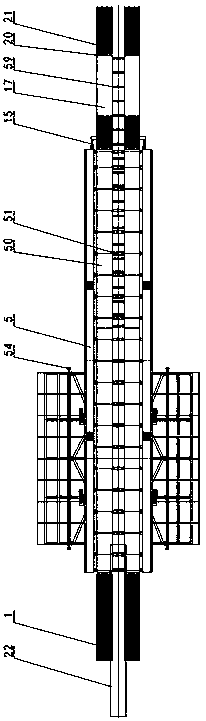

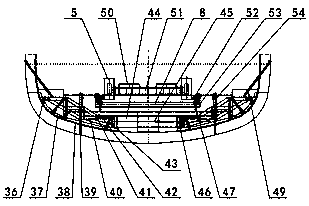

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Such as Figure 1-Figure 4 As shown, the multifunctional telescopic inverted arch trestle of the present invention comprises trestle main girder 5, front climbing ladder 16, rear climbing ladder 1, walking trolley 8, telescopic trestle 17, inverted arch formwork 26 and center ditch formwork 22, and walking trolley 8 installs It is placed under the trestle main girder 5 and can walk forward and backward. The front end of the trestle main girder 5 is placed on the main beam 29, and the main beam 29 is installed on the walkable main crawler chassis through the vertical main lifting hydraulic cylinder 30 and the main movable column 31. 28, the telescopic trestle 17 is positioned at the front portion below the trestle main girder 5 and can move forward and backward. The front portion of the telescopic trestle 17 is placed on the telescopic trestle crossbeam 18, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com