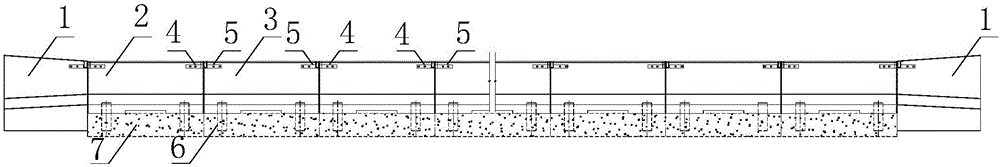

Wall type anti-collision movable rail

A technology of movable guardrails and guardrails, applied to roads, road safety devices, roads, etc., can solve the problems of large safety risks, collision avoidance ability not reaching the anti-collision level, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

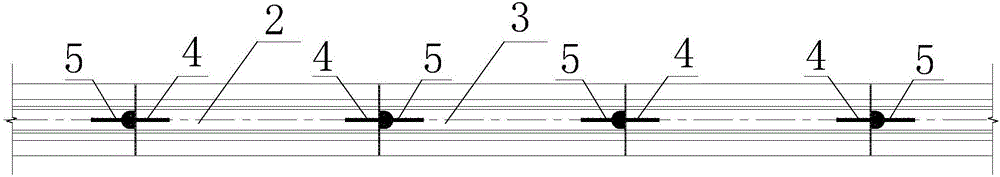

[0047] If there is a traffic accident on the expressway and the rescue vehicle cannot enter the scene, and diversion measures need to be taken, as long as the scene can pass by, you can easily carry the specially equipped small special tools to reach the accident scene quickly and unimpeded. Open the nearest movable guardrail in the middle, open a diversion channel, and quickly divert traffic.

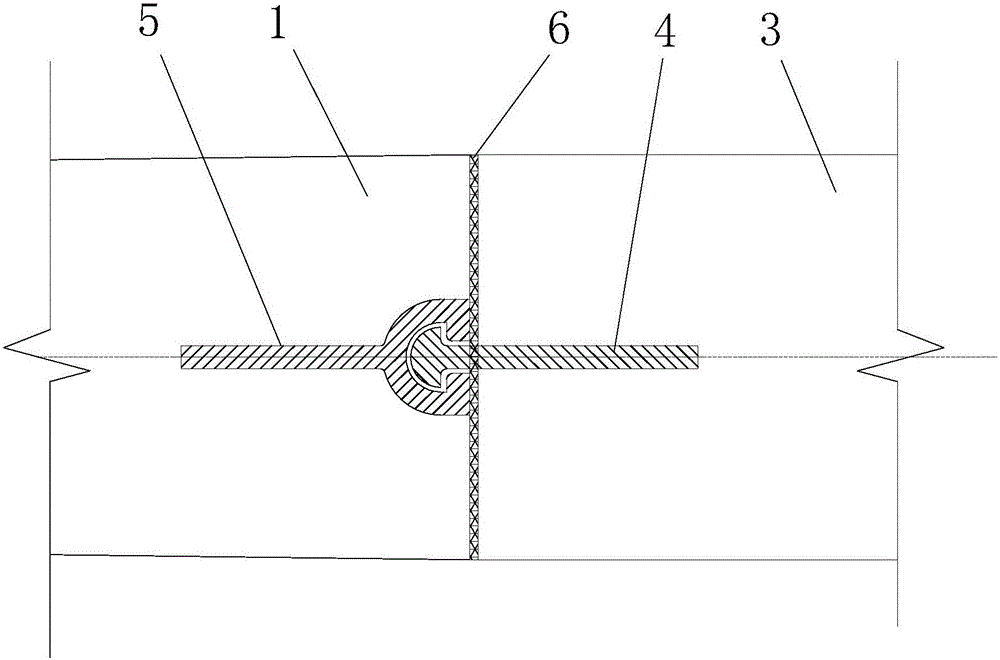

[0048] 1. Use a special hydraulic tool to jack up the movable guardrail unit with the guardrail male joint 4 (multiple sets of tools can be operated by multiple people at the same time).

[0049] 2. The jacking height is the height position where the pre-embedded component 6 can be separated.

[0050] 3. Install universal movable casters at the predetermined position of the raised movable guardrail unit.

[0051] 4. After the hydraulic tool is depressurized, the movable guardrail unit and the universal movable caster are integrated into one.

[0052] 5. Push the raised movable guardrai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com