Passive padiator railway metallic sound barrier system

A sound barrier and damping technology, which is applied in the field of damping railway metal sound barrier system, can solve problems such as poor structural rigidity, cracking of cement board, loss of efficacy, etc., and achieve the goal of improving fatigue life, structural safety and overall rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

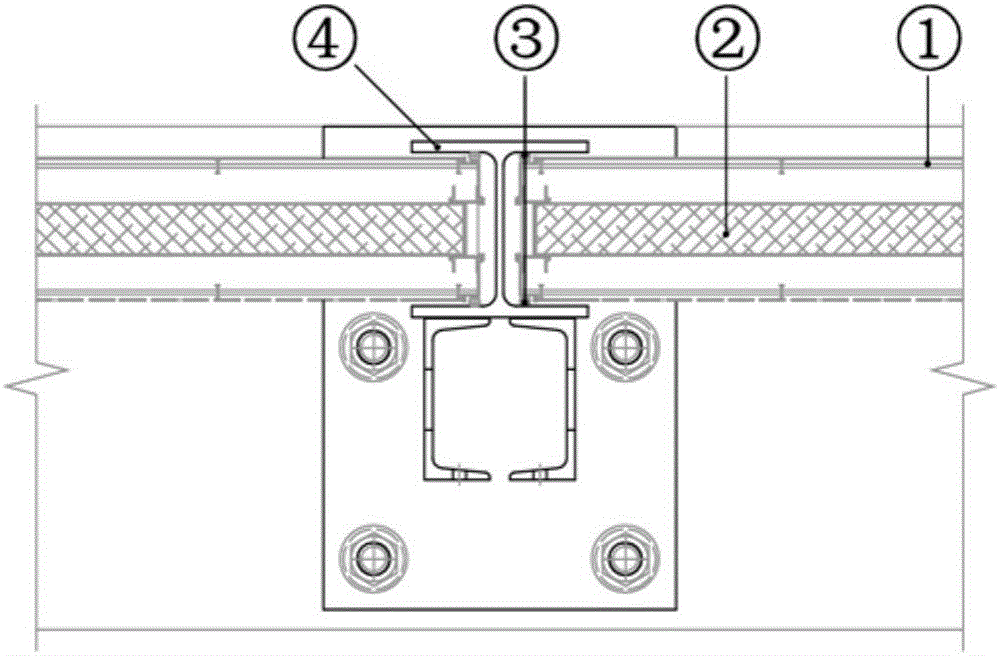

[0044] Such as Picture 1-1 As shown, it is a schematic diagram of the side structure of the damping type railway metal sound barrier system of the present invention, as Figure 1-2 As shown, it is a schematic diagram of the front structure of the damping railway metal sound barrier system of the present invention, as Figure 1-3As shown, it is a top view structure schematic diagram of the damping type railway metal sound barrier system of the present invention, wherein, ① is the unit plate shell of the damping type metal sound barrier; ② is the sound absorption component of the unit plate; ③ is the damping device for installation; ④ is the acoustic Barrier offset steel uprights. Damping railway metal sound barrier system, including damping type railway Beijing-Shanghai sound barrier unit plate shell ①, unit plate sound absorption component ②, damping device for installation ③ and sound barrier offset steel column ④; damping type metal sound barrier unit plate The shell ① is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com