250DWL-82 basic fabric for automotive interior trim skin

A technology for automotive interiors and skins, which is used in motor vehicles, fabric surface trimming, textile material processing, etc., can solve the problems of high production cost, heavy gram weight, large thickness, etc., so as to reduce the use cost, reduce gram weight and The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

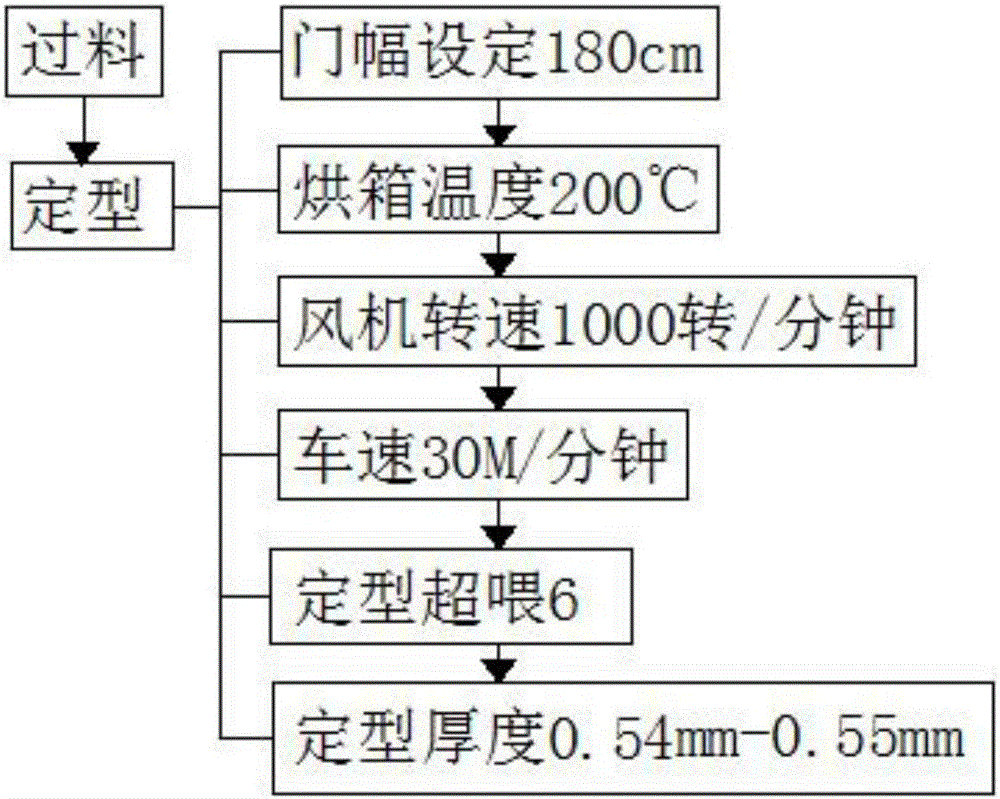

[0029] Such as Figure 1-Figure 3 Shown, the 250D WL-82 base cloth that is used for automobile interior skin of the present invention comprises following technology:

[0030] The first step: gray cloth weaving.

[0031] Raw material: 250D / 96F DTY low stretch wire;

[0032] Weaving machine size: 30 inches in diameter;

[0033] Knitting needles: the number of needles is 18 needles / inch, and the total number of needles is 1740 pieces;

[0034] Yarn length: the length of one yarn is 15cm / 50 stitches, and so on.

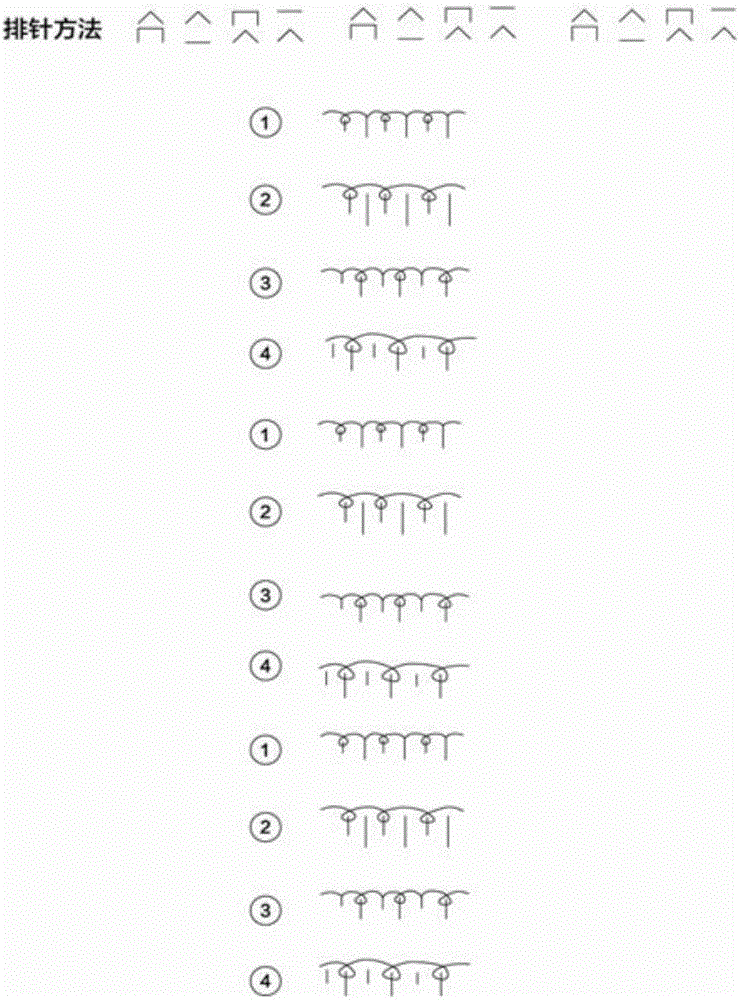

[0035] Needle row process:

[0036] The way of pin arrangement is AB, and so on. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com