Drafting device

A drafting device and drafting technology, applied to drafting equipment, textiles, papermaking, spinning machines, etc., can solve problems such as difficulties and achieve the effect of less risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

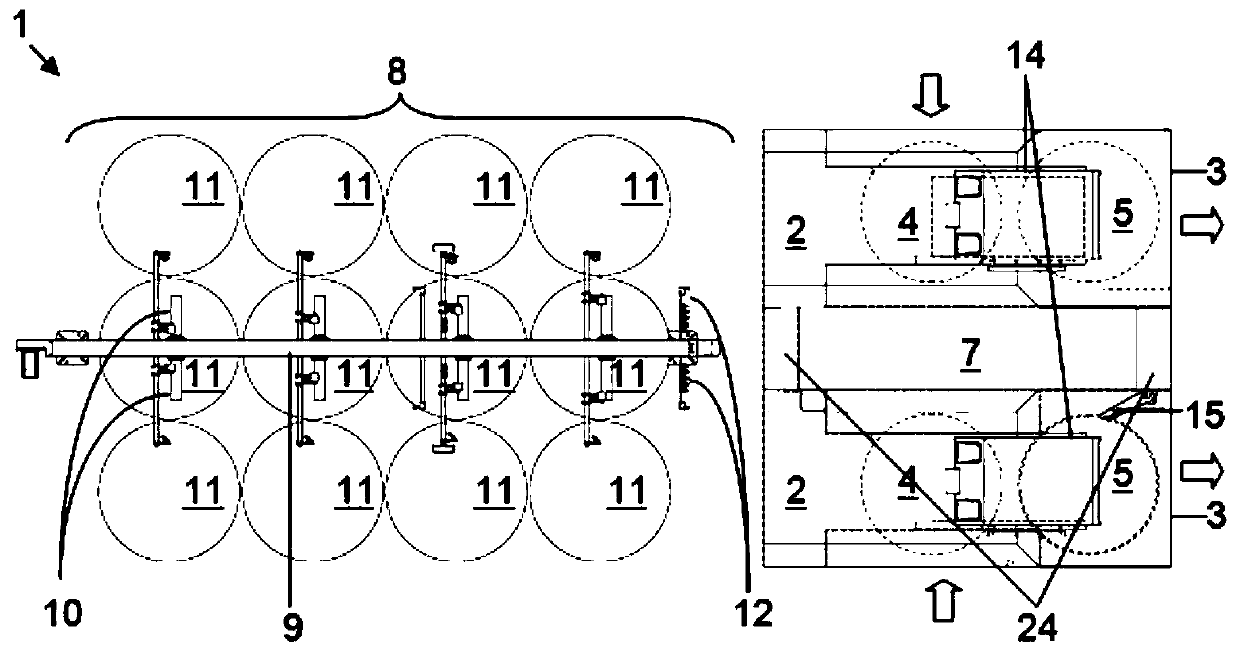

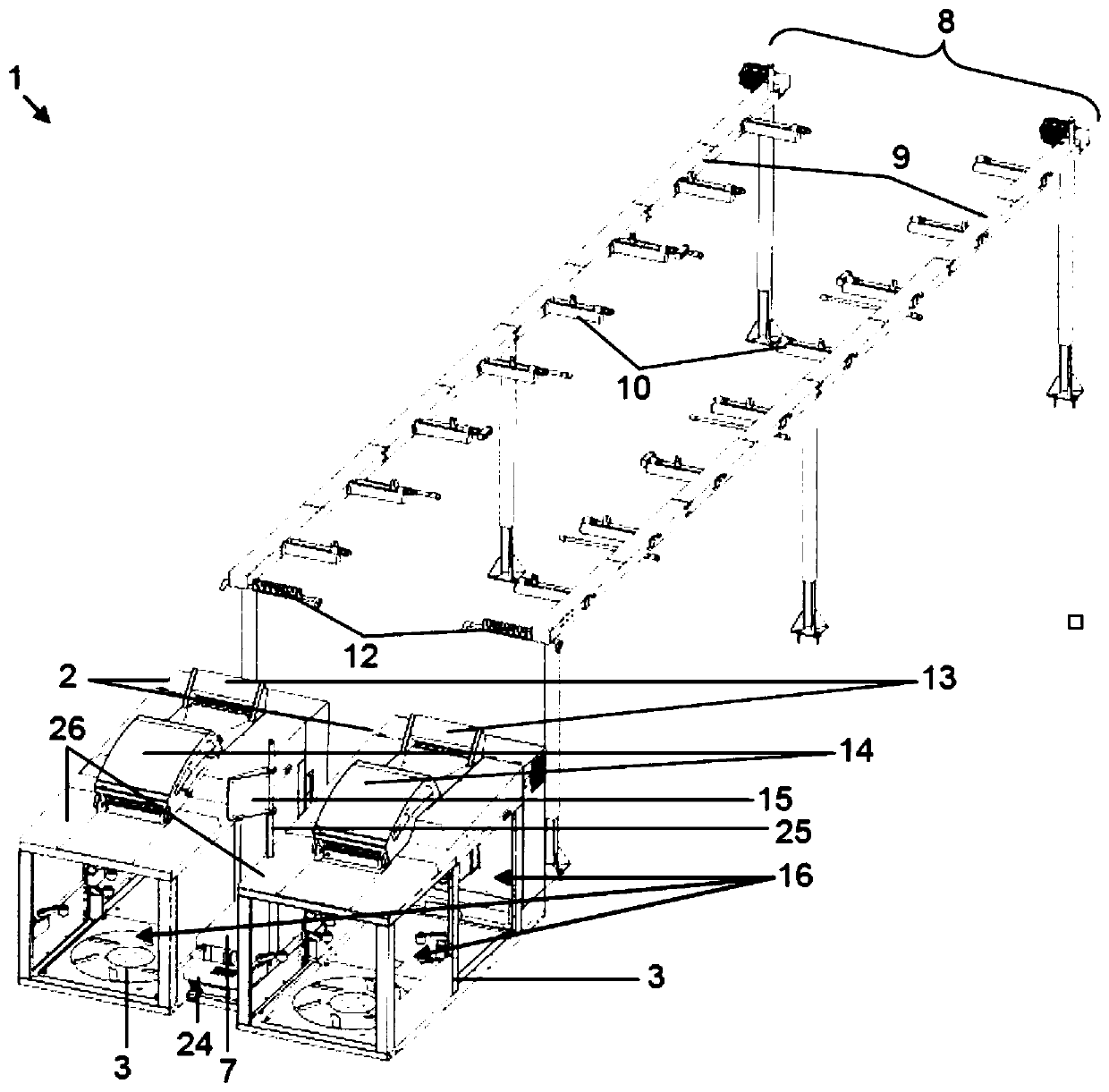

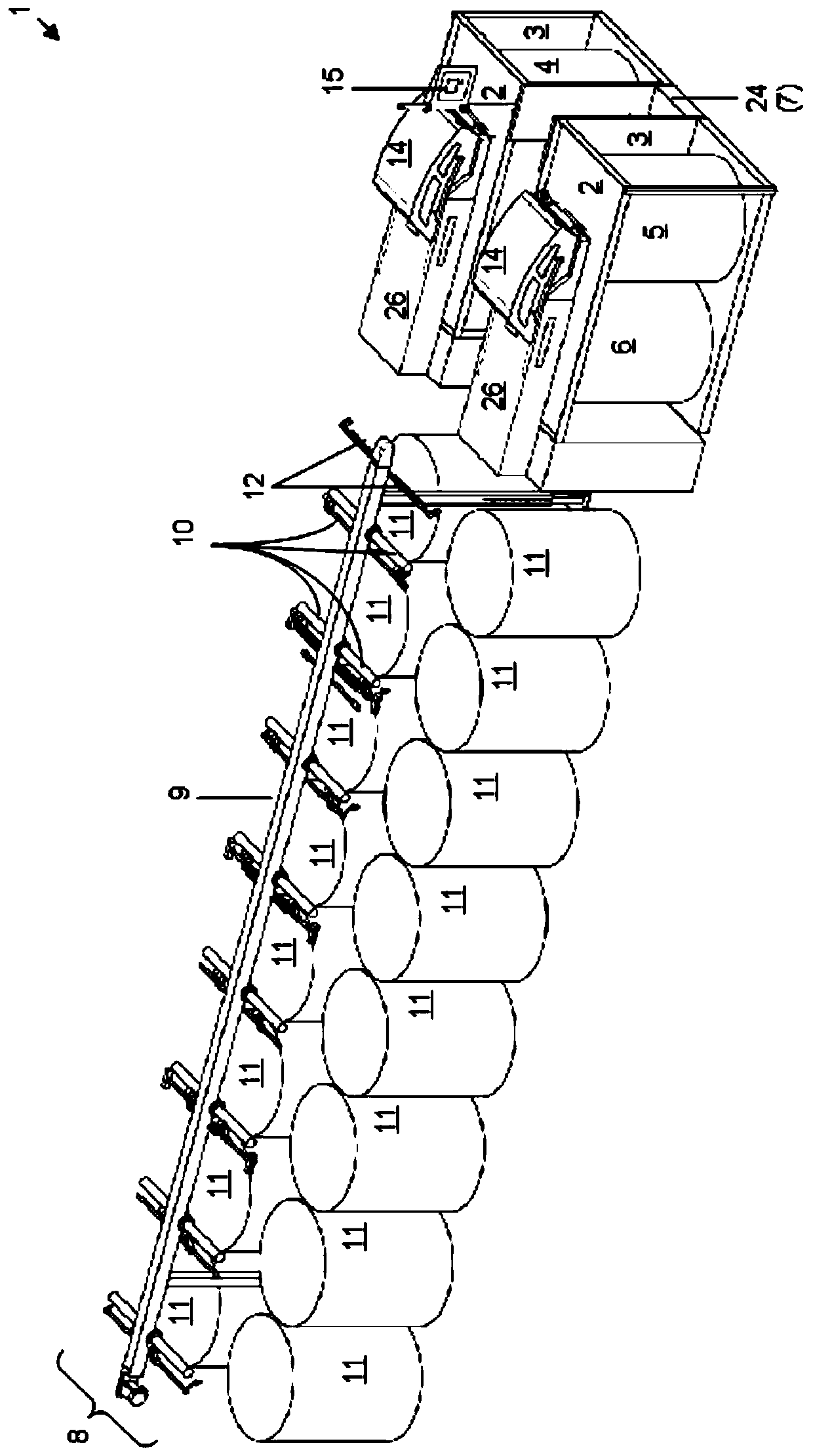

[0033] figure 1 A drafting device 1 according to a first embodiment of the invention is shown in plan view, which is designed as a double-head draw frame.

[0034] The double-head draw frame 1 comprises two drafting mechanisms 2 which are arranged above the respective can changer 3 .

[0035] The drafting unit 2 is designed in a conventional manner, ie has drafting rollers and corresponding sensor devices for the thickness of the fiber web. Furthermore, each drafting mechanism 2 has its own, invisible drive. The drives and drafting rollers are preferably arranged below the respective housing cover 14 .

[0036] Each can changer 3 is designed as a linear changer by way of example. That is to say, a correspondingly empty can 4 is viewed along the longitudinal extension of the double-head draw frame 1 according to figure 1 That is to say horizontally, laterally from the outer side of the respective can changing device 3 into the can changing device 3 . this point in figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com