Heating furnace temperature control method based on simulation model

A technology of simulation model and control method, applied in heat treatment process control, heat treatment furnace, furnace, etc., can solve problems such as unstable control, unstable temperature difference of billet, and drastic changes in calculation results, so as to avoid frequent drastic changes and realize precise control , to achieve the effect of stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

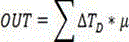

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] Taking the rod and wire heating furnace as an example, the furnace body is 20 meters long and is divided into 3 heating sections: the first heating section, the second heating section and the soaking section; its production scale is 120t / h, and the scale of heated billets is divided into 5 types , the average weight of each billet ranges from 3t to 5t; there are at most 60 billets in the furnace, and under the general production rhythm, one steel billet is tapped in an average of 2 minutes; the steel temperature required to be released from the furnace is 1290°C, and the temperature of the steel into the furnace is divided into hot steel and cold steel , The temperature of hot steel is 700-800°C, and the temperature of cold steel is normal temperature; the exhaust gas temperature is controlled at about 200°C.

[0018] Based on comprehensive con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com