A powder metallurgy tempering furnace

A powder metallurgy and tempering furnace technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of large oil fume, difficult to collect and process oil fume, and excessive oil fume concentration in the production workshop, and achieve the effect of reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

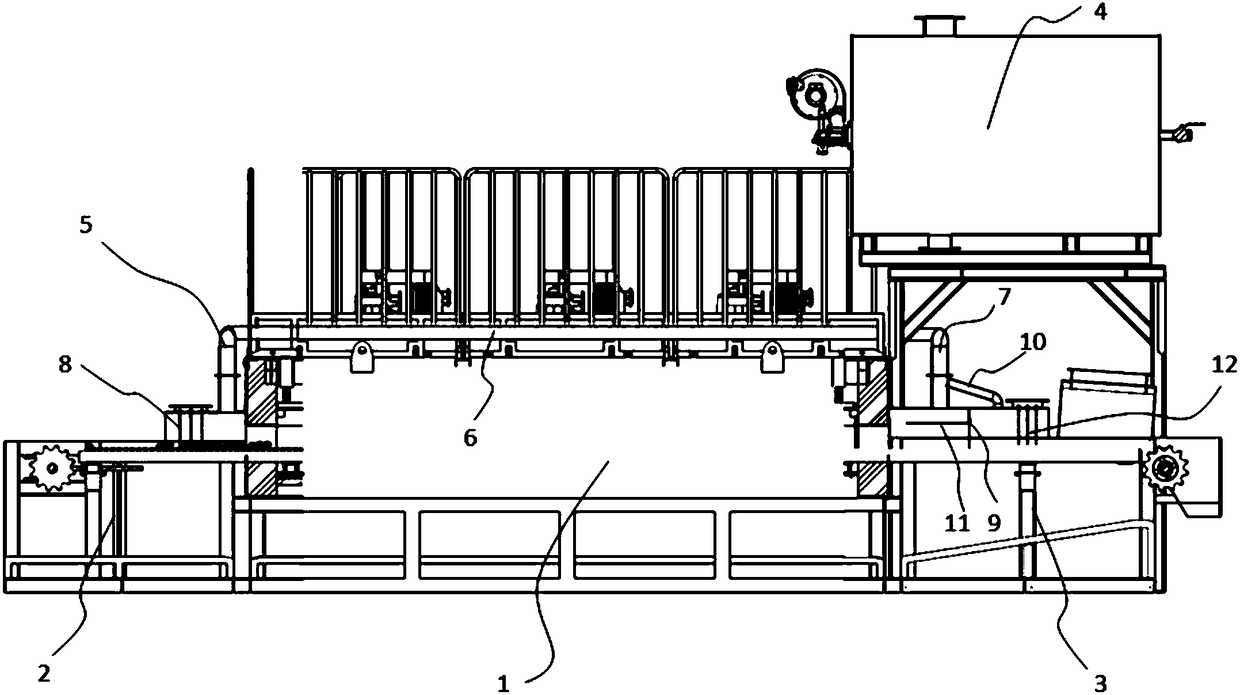

[0013] Such as figure 1 As shown, in a specific embodiment, the powder metallurgy tempering furnace of the present invention includes a tempering furnace body 1, a feed frame 2, a discharge frame 3, an incineration device 4, a fume collection pipe 5 at the feed port, and a fume collection main pipe 6 And the oil fume collection pipe 7 at the discharge port.

[0014] The feeding frame 2 is arranged on the side of the feeding port of the tempering furnace body 1 , and the discharging frame 3 is arranged on the side of the discharging port of the tempering furnace body 1 . The feed frame 2 is provided with a fume collection chamber (not shown) at the feed port, and one end of the fume collection chamber is connected through the feed port of the tempering furnace body 1 . The discharge frame 3 is provided with a fume collection chamber at the discharge port (not shown), and one end of the fume collection chamber at the discharge port is connected through the discharge port of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com