Nanometer fluid for compact oil reservoir imbibition oil discharging and preparation method thereof

A technology for tight oil reservoirs and nanofluids, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of difficult water injection, poor pore connectivity of reservoirs, increased water flow resistance and water injection pressure, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

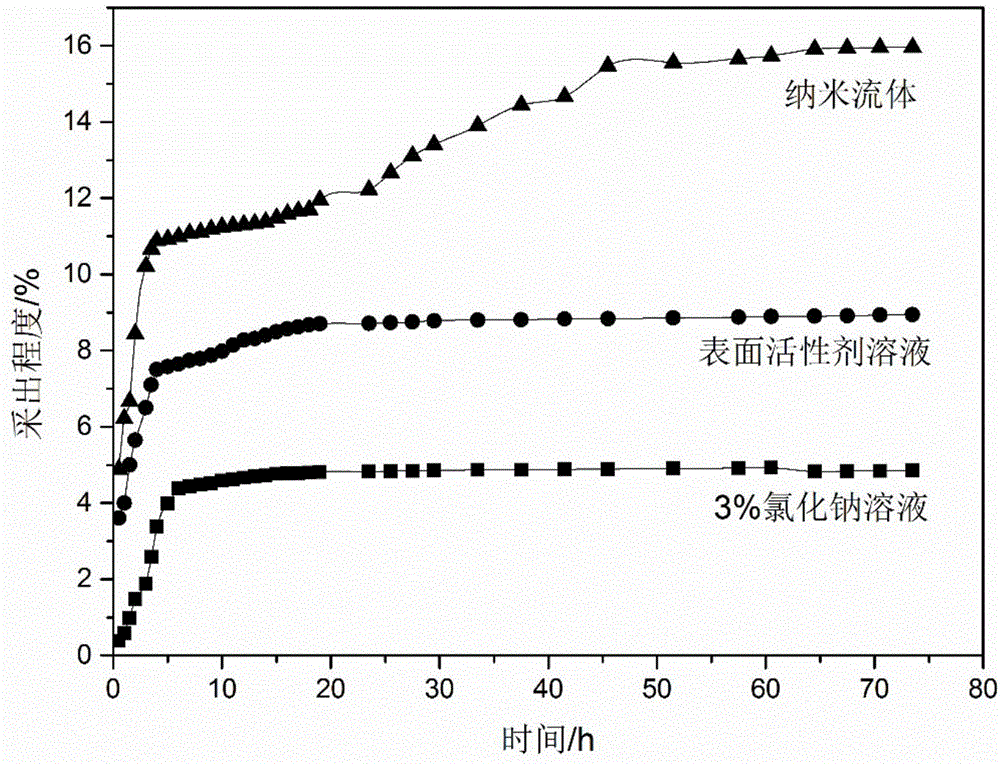

Embodiment 1

[0020] Add 0.40g of auxiliary dispersant ethanol to 0.5g of hydrophobic nano-silica, stir evenly, add 0.5g of Triton-100, and add 98.6g of water at the same time, after stirring for 5min, ultrasonically disperse for 40min, then put the above solution in 80 ℃ in a water bath for 1 hour, the nanofluid for imbibition and oil discharge can be obtained.

Embodiment 2

[0022] Add 0.40g of auxiliary dispersant ethanol to 0.5g of hydrophobic nano-silica, stir manually at room temperature, add 0.5g of Triton-100, and add 98.5g of water at the same time, stir for 5min, ultrasonically disperse for 40min, and then dissolve the above solution Put it in a water bath at 60°C for 1 hour to obtain the nanofluid for permeation and oil discharge.

Embodiment 3

[0024] Add 0.80g of auxiliary dispersant ethanol to 0.1g of hydrophobic nano-silica, stir well, add 0.01g of polyethylene glycol 600, and add 99.09g of water at the same time, stir for 5min, ultrasonically disperse for 40min, and then put the above solution in 80 ℃ in a water bath for 1 hour, the nanofluid for imbibition and oil discharge can be obtained.

PUM

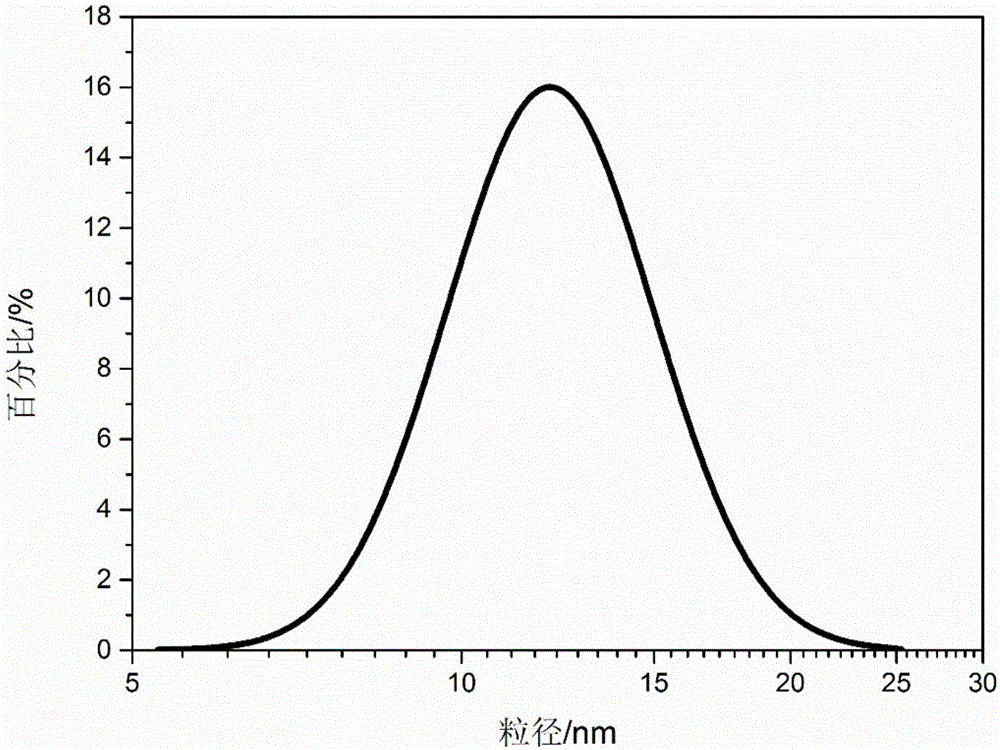

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com