Material used for a fabric sealing ring

A sealing ring and rubber material technology, which is applied in the field of natural latex materials for sandwich fabric sealing rings, can solve the problems of complex production process, easy aging, easy deformation, etc., and achieves rich sources, improved tensile strength and good resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

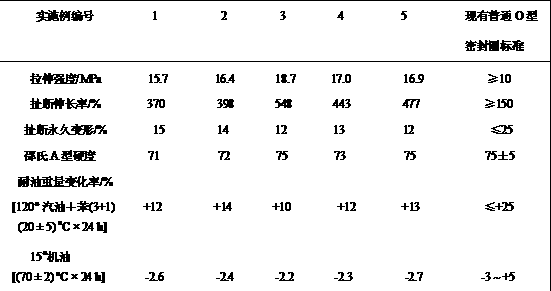

Examples

Embodiment 1

[0015] The rubber material used for the fabric sealing ring of the present embodiment is made of 100 parts of natural glue (dry glue) with a glue content of 35%, dry plain cotton canvas with a moisture content of less than 1.0%, and 45 parts by mass fraction. The compounding agent is made; wherein the compounding agent is composed of carbon black, zinc oxide, vulcanization accelerator, stearic acid, vulcanizing agent and anti-aging agent D in a mass ratio of 30:8:1.5:2:2.5:1.

[0016] The natural rubber latex described in this embodiment is a commercially available industrial grade. The vulcanization accelerator is 2-mercaptobenzothiazole, namely accelerator M. The vulcanizing agent is sulfur. The anti-aging agent D is N-phenyl-2-naphthylamine. Described vulcanization accelerator, vulcanization agent and antioxidant D are commercially available.

[0017] The preparation method of the rubber material for the fabric sealing ring by the dipping method in this embodiment is car...

Embodiment 2

[0018] The preparation method of embodiment 2~embodiment 5 is identical with embodiment 1, and raw material composition is respectively as follows:

Embodiment 2

[0020] The rubber material used for the fabric sealing ring of the present embodiment is made of 100 parts of natural glue (dry glue) with a glue content of 35%, dry plain cotton canvas with a moisture content of less than 1.0%, and 50 parts by mass fraction. The compounding agent is made; wherein the compounding agent is composed of carbon black, zinc oxide, vulcanization accelerator, stearic acid, vulcanizing agent and anti-aging agent D in a mass ratio of 35:8:1.5:2:2.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com