Wire tapping control system and trolley pole with system

A control system and a rod cavity technology, applied in the field of wiring control systems and collector rods, can solve the problem of low degree of automation, and achieve the effect of meeting the needs of actual working conditions, high control precision and sufficient power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

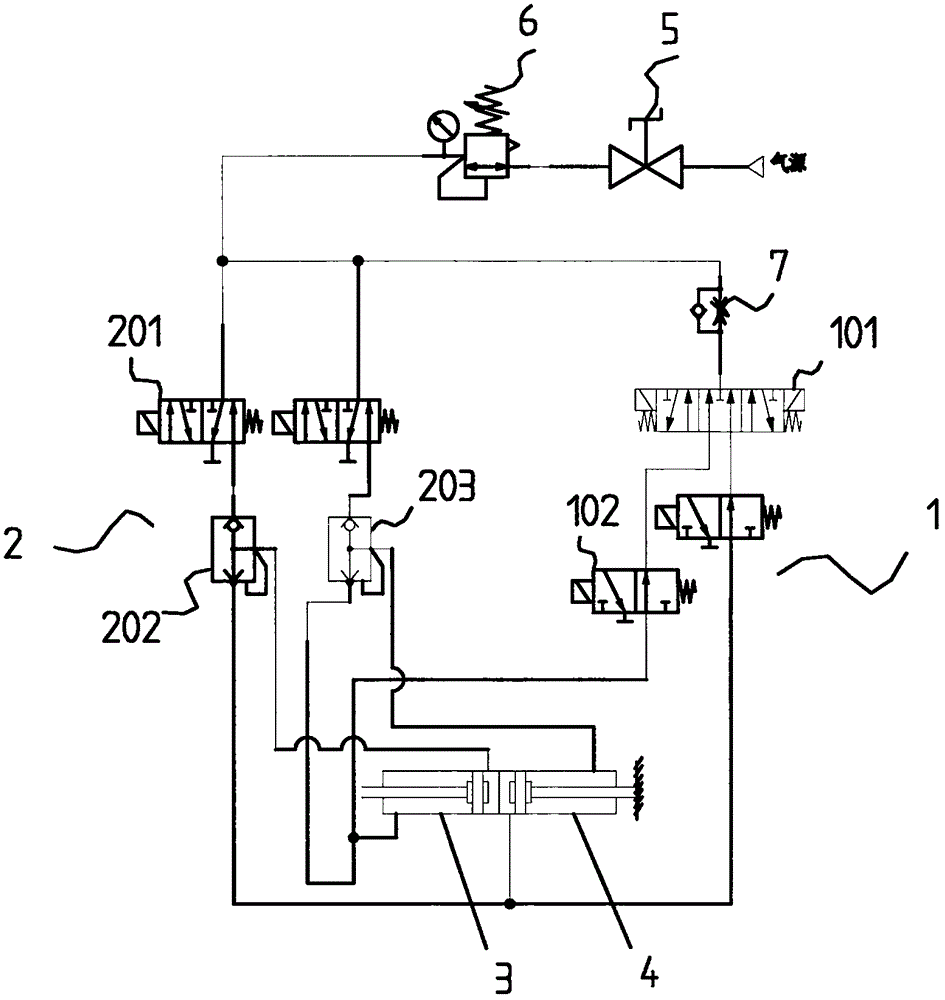

Embodiment 1

[0040] The first type of wiring control system for collector poles includes an air source, which is usually supplied by the vehicle itself, and is connected to the air source through an air pipe, and the centering system 2 and the swing system 1 are connected at the end of the air pipe. Wherein the centering system 2 is connected in parallel with the swinging system 1, that is, branch pipeline one and branch pipeline two are formed from the end of the trachea, the centering system 2 is arranged on the branch pipeline one, and the swinging system 1 is mainly Arranged on the second branch pipeline, and merge the airflow of the swing system 1 into the return system 2.

[0041] The centering system 2 includes a solenoid valve 201, the input end of the solenoid valve is connected to the end of the branch pipeline 1, and the left and right pipelines are arranged on the solenoid valve, which are the first pipeline and the second pipeline, Wherein, the first pipeline is connected with...

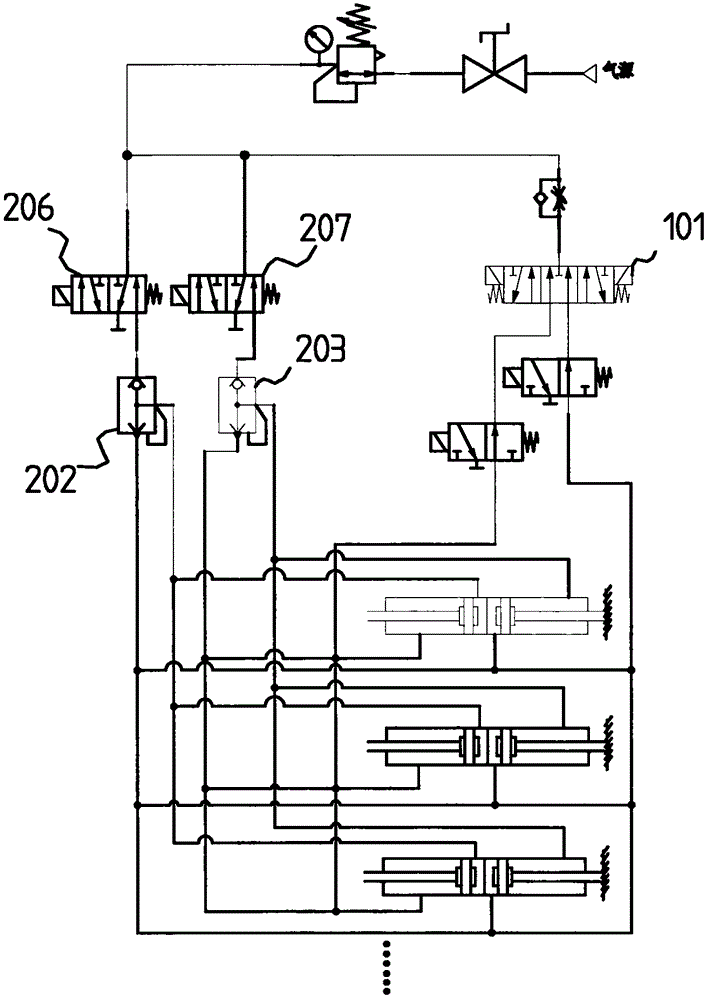

Embodiment 2

[0065] The second take-up control system for collector poles is the same as Embodiment 1, including an air source, a centering system 2 and a swing system 1 connected to the air source through a gas pipe, and the centering system 2 includes a control system unit, the control unit is composed of a solenoid valve 1 206 and a solenoid valve 2 207, and the air pipe end part is divided into a branch pipeline 1, a branch pipeline 2 and a branch pipeline 3, the branch pipeline 1 is connected with the solenoid valve 1 206, and the branch pipeline Road two is connected with solenoid valve two 207, and branch pipeline three is connected with swing system 1.

[0066] Solenoid valve one 206 is connected with the first intake selection valve 202, solenoid valve two 207 is connected with the second intake selection valve 203, the first selection valve is connected with the first air passage 204 and the second air passage 205, the second intake selection valve The gas selection valve 203 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com