A fully automatic cam-controlled high-speed bronzing machine

A technology of cam control and hot stamping machine, which is applied in the direction of rotary printing machine, printing machine, gold powder printing, etc. It can solve the problems of slow stamping speed and unstable stamping quality, and achieve short stamping cycle, save labor cost and high stamping efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

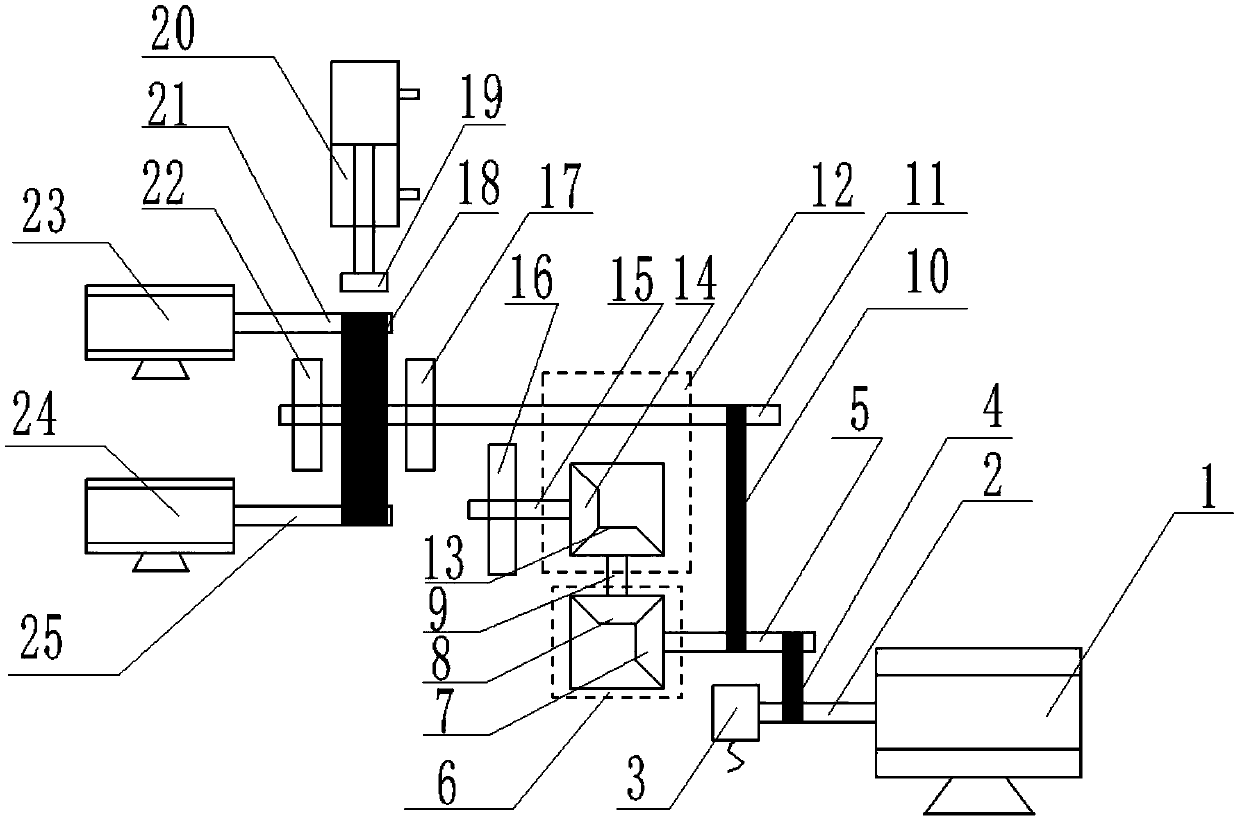

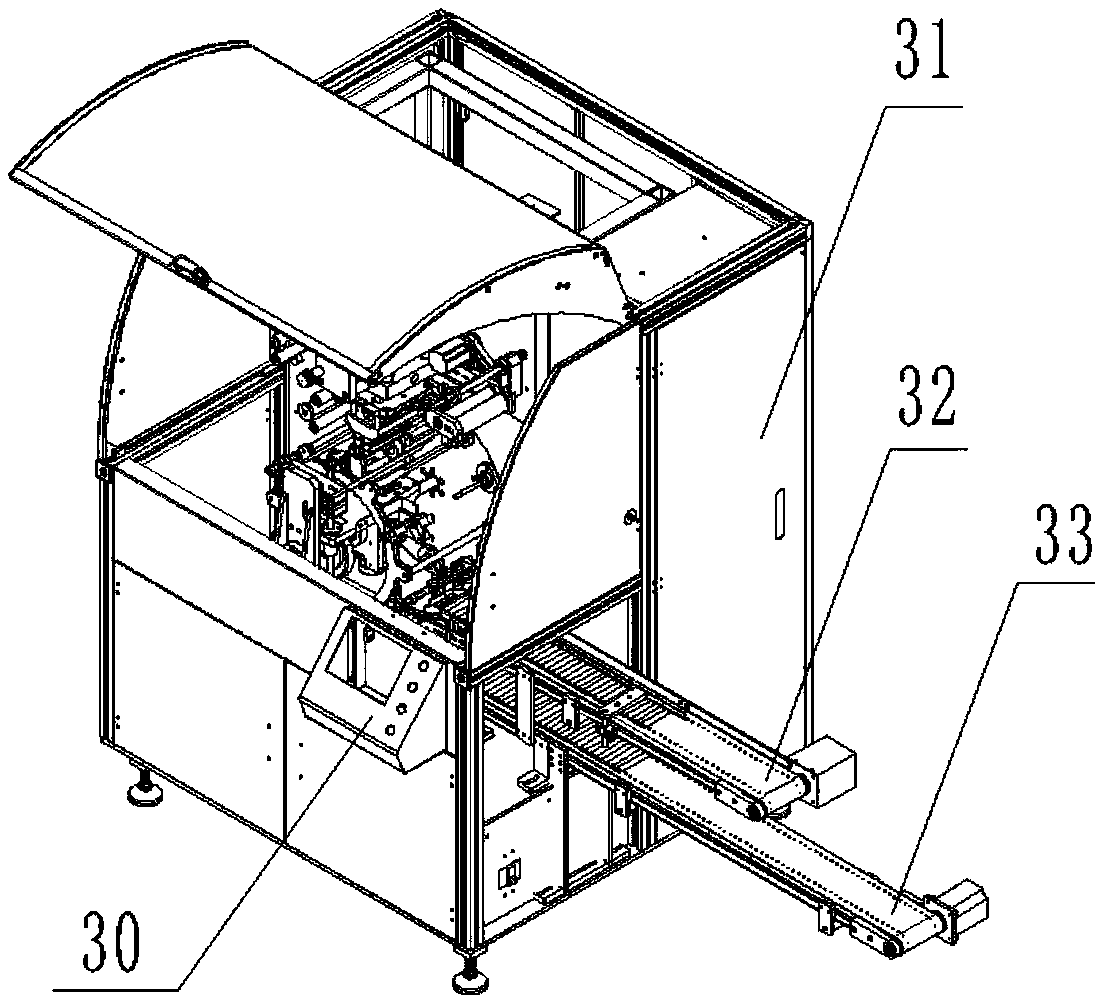

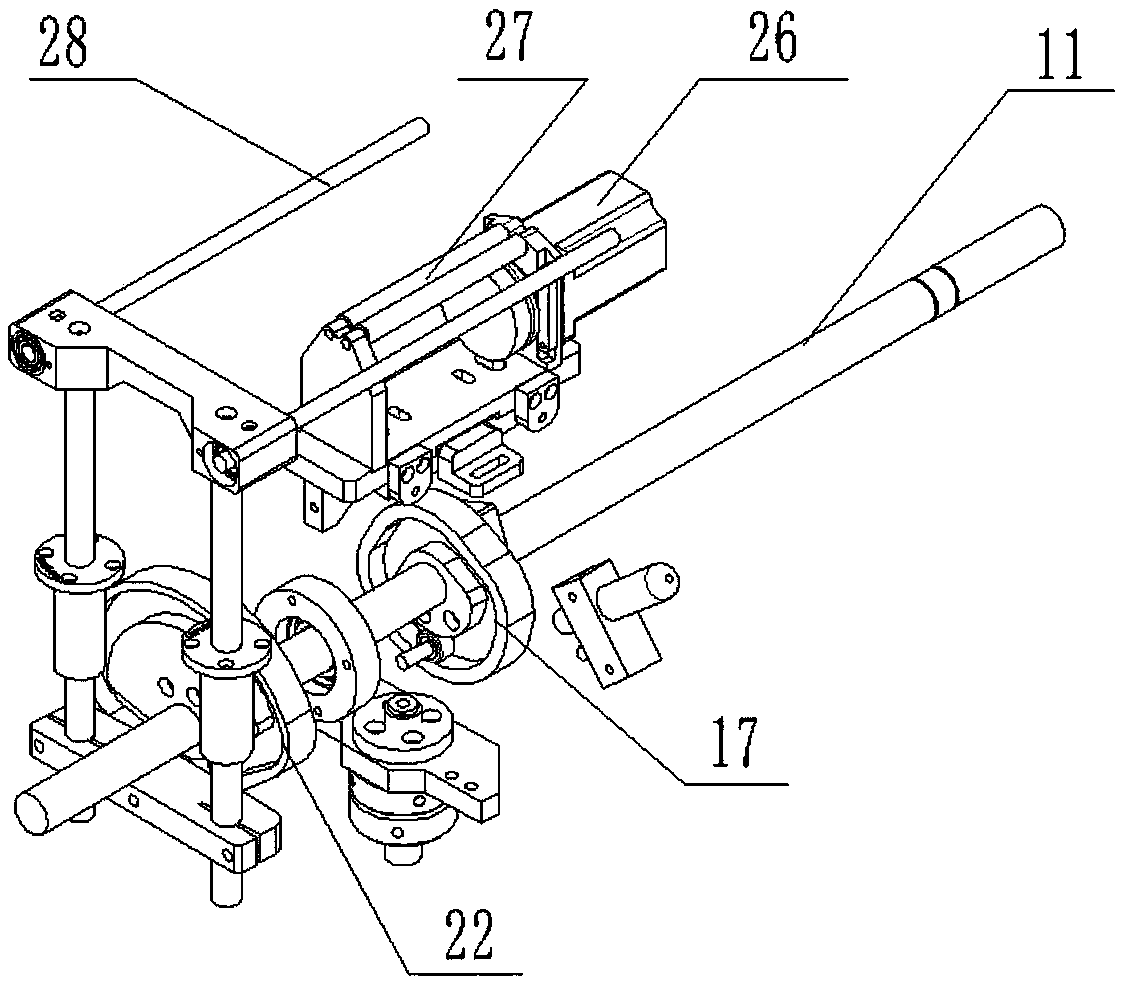

[0044] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , high-speed bronzing of round products: firstly, the operator opens the control panel 30, starts the motor 1 and the control motor of the feeding and conveying mechanical system 32, and puts the round product 29 on the conveyor belt of the feeding mechanical system 32, and the feeding conveyor will The circular product 29 is transported to the position below the suction cup of the feeding manipulator. The suction cup of the feeding manipulator sucks the round product 29 and places it in the correct direction of the round product 29. If the direction is opposite, the rotary cylinder above the suction cup rotates 180 After the degree, put it on the conveyer belt again, when the round product 29 is transferred to the product loading and clamping position, the clamp on the turntable 16 clamps the round product 29, and the cam divider 12 is connected with the fourth bevel gear 14 The fourth transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com