Compression-resistance anti-bacteria pharmaceutical packaging composite film

A composite film and packaging technology, applied in the field of pharmaceutical packaging, can solve the problems of drug pollution, drug damage, drug extrusion, etc., achieve good shock absorption and compression resistance, extend shelf life, and keep clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

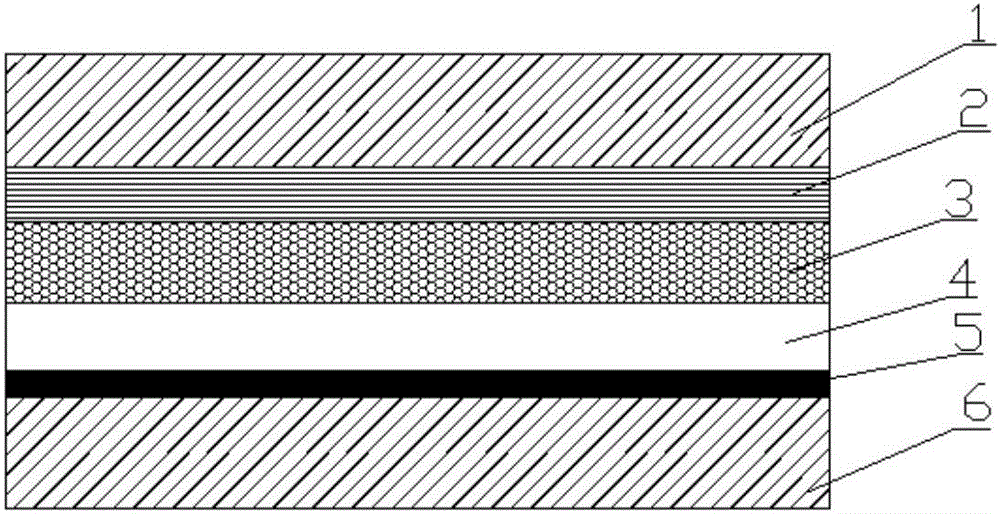

[0023] A composite film for anti-compressive and anti-bacterial medicine packaging, the composite film is sequentially composed of a first polyethylene layer 1, a cellophane layer 2, an air bubble layer 3, an aluminum foil layer 4, an aluminized polyethylene film layer 5 and The second polyethylene layer 6, between the first polyethylene layer 1 and the cellophane layer 2, between the cellophane layer 2 and the bubble layer 3, between the bubble layer 3 and the aluminum foil layer 4, between the aluminum foil layer 4 and the aluminized polyethylene Between the film layers 5, between the aluminized polyethylene film layer 5 and the second polyethylene layer 6, all are bonded and connected by an adhesive, and the bubbles in the bubble layer 3 are all filled with nano-scale foam particles. Both the first polyethylene layer 1 and the second polyethylene layer 6 are added with an antibacterial agent, and the antibacterial agent accounts for 1%-3% of the total content of the first po...

Embodiment 2

[0030] The difference between this embodiment and Example 1 is that the nanoscale foam particles are rubber particles; the thickness of the first polyethylene layer 1 and the second polyethylene layer 6 is 0.2 mm; the thickness of the cellophane layer 2 is 0.03 mm. mm; the thickness of the bubble layer 3 is 0.05mm; the thickness of the aluminum foil layer 4 is 0.04mm; the thickness of the aluminized polyethylene film layer 5 is 0.02mm; the thickness of the adhesive is 0.006mm.

Embodiment 3

[0032] The difference between this embodiment and embodiment 2 is that the nanoscale foam particles are polyethylene particles; the thickness of the first polyethylene layer 1 and the second polyethylene layer 6 is 0.3mm; the thickness of the cellophane layer 2 is 0.04mm; the thickness of the air bubble layer 3 is 0.06mm; the thickness of the aluminum foil layer 4 is 0.06mm; the thickness of the aluminized polyethylene film layer 5 is 0.03mm; the thickness of the adhesive is 0.009mm .

[0033] The use process of the composite film in the present invention is as follows: during packaging, the medicine is contacted with the second polyethylene layer 6, the first polyethylene layer 1 is placed outside, the first polyethylene layer 1 plays the role of medicine, and the first polyethylene layer Layer 1 and the second polyethylene layer 6 are filled with antibacterial agents, even if the first polyethylene layer 1 is damaged, harmful substances cannot enter the second polyethylene l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com