3D printer and pressure detection method and pressure compensation method thereof

A 3D printer, pressure compensation technology, applied in the direction of 3D object support structure, coating device, additive manufacturing, etc., can solve problems such as reducing the printing quality of 3D printers, nozzle collision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

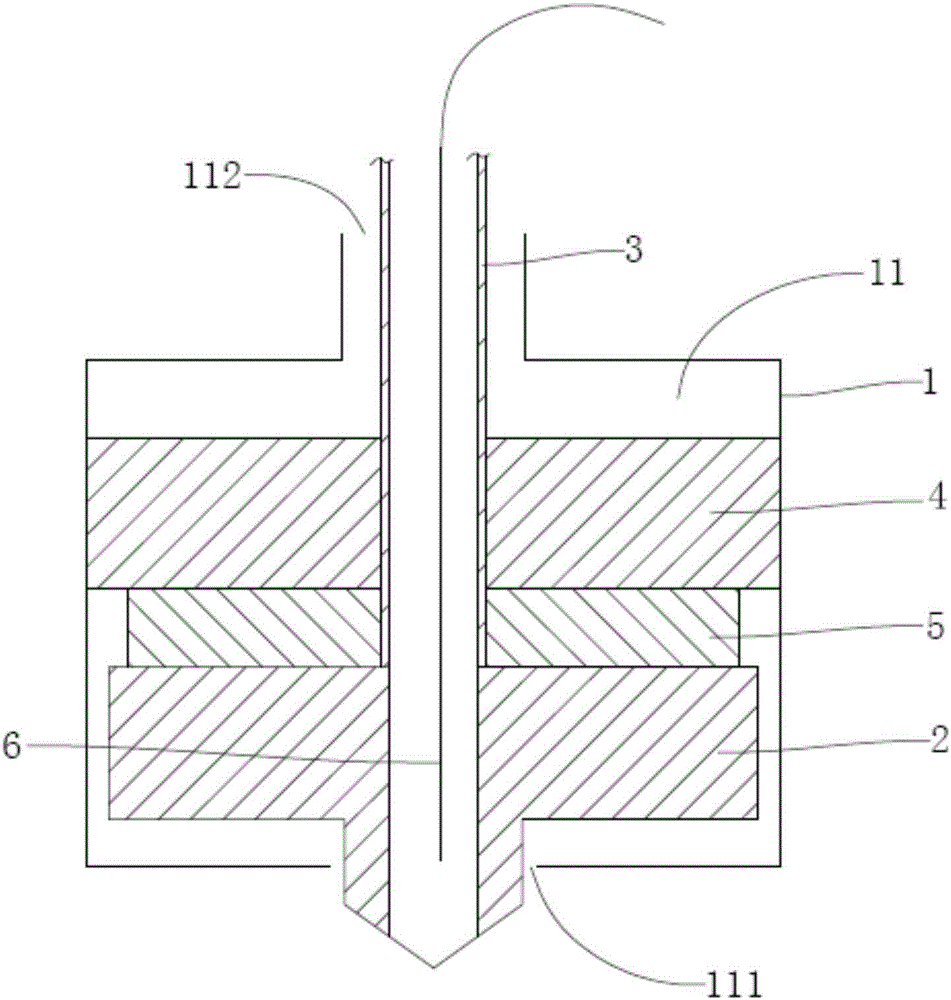

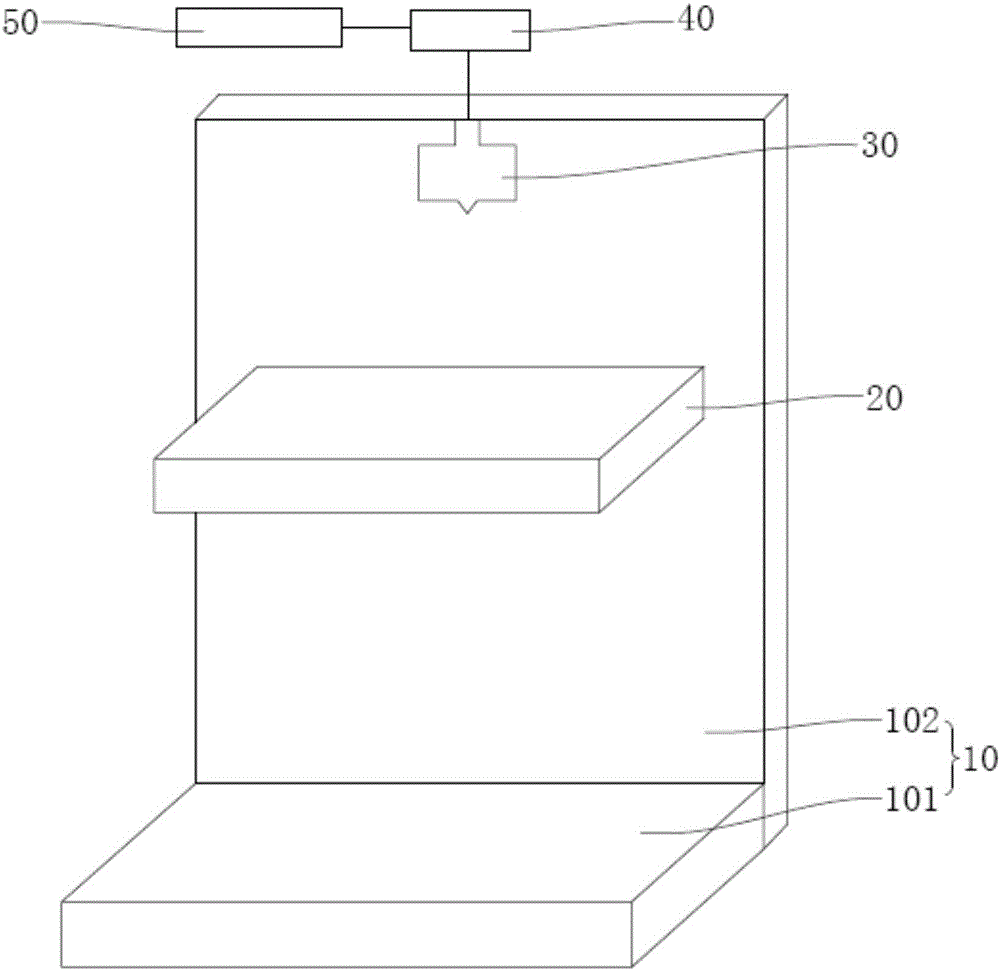

[0032] refer to figure 1 and figure 2 , a 3D printer, comprising a mounting bracket 10, a workbench 20 and a spray head 30, the spray head 30 and the workbench 20 are arranged on the mounting bracket 10 and the spray head 30 is located above the workbench 20, and the spray head 30 includes a nozzle 2, a delivery pipe 3 and an extrusion Mechanism 4, the delivery pipe 3 is connected to the nozzle 2, and the extrusion mechanism 4 is connected to the delivery pipe 3. During the working process of the extrusion mechanism 4, the molten material 6 in the delivery pipe 3 is sprayed on the workbench 20 through the nozzle 2 .

[0033] refer to figure 1 , the solid material enters the feeding pipe 3 corresponding to the nozzle 2 after being melted at high temperature, and the feeding pipe 3 corresponding to the extruding mechanism 4 (under the action of the extruding mechanism 4 undergoes elastic deformation. Corresponding to the extruding mechanism 4 During the process of elastic de...

Embodiment 2

[0054] In this embodiment, the 3D printer is the 3D printer in Embodiment 1.

[0055] The difference from Embodiment 1 is that in this embodiment, the 3D printer has a pressure compensation method.

[0056] A pressure compensation method for a 3D printer, comprising the steps of:

[0057] S01) The controller sets the pressure signals P1, P2 and P, P1

[0058] S02) The nozzle moves relative to the workbench until the force of the extrusion nozzle on the workbench is transmitted to the controller through the sensor. During the process of transmitting the force of the extrusion nozzle on the workbench to the controller through the sensor, the controller Signal, calculate and generate height values at different positions of the workbench.

[0059] In this embodiment, "the nozzle moves relative to the worktable" has the following two ways of understanding: 1. First, the nozzle moves along its height direction until the molten material ejected from the outlet on the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com