Adjustable multipurpose tool

A multi-tool and work technology, applied in the field of tools, can solve the problems of shortening the construction period, high work efficiency, prolonging the construction period, etc., and achieve the effect of shortening the construction period and improving the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

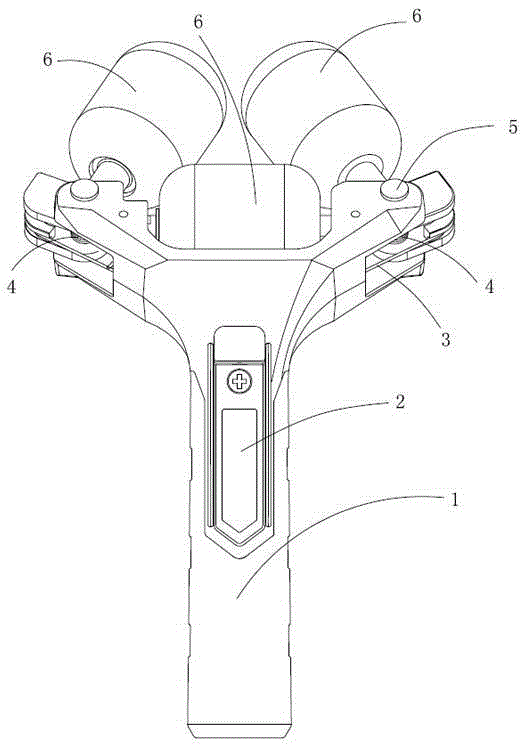

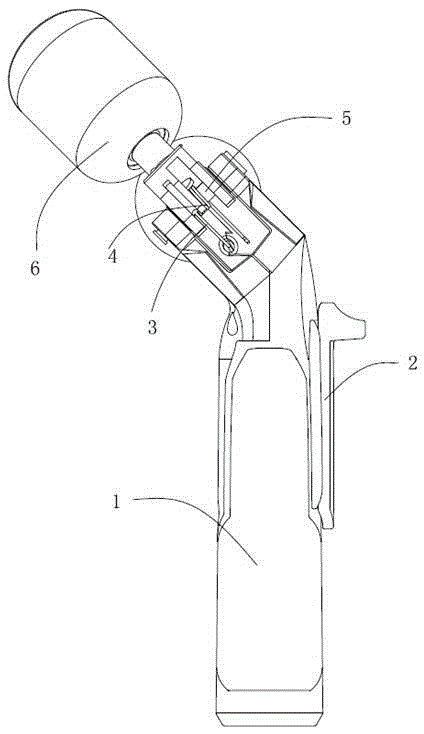

[0027] Embodiment 1: a kind of adjustable multipurpose roller (see figure 1 figure 2 ), including a handle 1, the front end of the handle is in a structure of gradually expanding width, and the front end of the handle is bent relative to the grip of the handle.

[0028] A working part 6 is fixedly installed in the middle position of the front end of the handle, and a working part 6 is hinged on both sides of the front end of the handle through a pin shaft 5. The hinged working parts can rotate around the pin shaft, and the three working parts are combined to form an adaptive curved surface or Three planar working contact surfaces.

[0029] A return torsion spring 4 is sleeved on the bearing pin, and the return torsion spring drives the hinged working parts to be in an automatic closing state. A steel wire rope 3 is connected to the hinged working part, and the steel wire rope penetrates into the handle, which is provided with a manual component 2 that can slide relative to ...

Embodiment 2

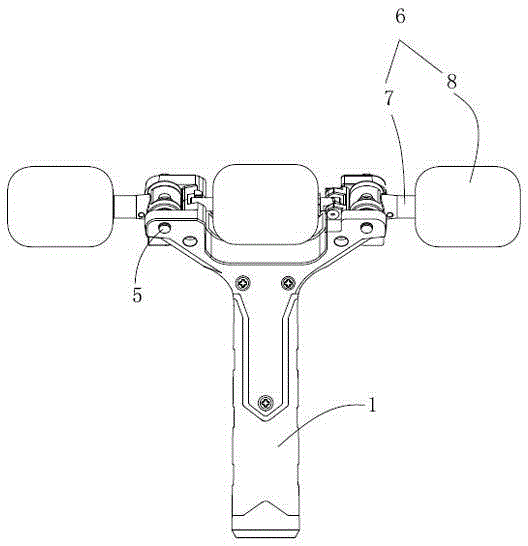

[0031] Embodiment 2: a kind of adjustable multipurpose brush (see Figure 4 Figure 5 ), including a handle 1, the front end of the handle is in a structure of gradually expanding width, and the front end of the handle is bent relative to the grip of the handle.

[0032] A working part 6 is fixedly installed in the middle position of the front end of the handle, and a working part 6 is hinged on both sides of the front end of the handle through a pin shaft 5. The hinged working parts can rotate around the pin shaft, and the three working parts are combined to form an adaptive curved surface or Three planar working contact surfaces.

[0033] A return torsion spring 4 is sleeved on the bearing pin, and the return torsion spring drives the hinged working parts to be in an automatic closing state. The hinged working part extends to the handle side with a manual part 2 integrated with the working part, and the manual parts of the two working parts are outwardly stretched relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com