Special tool and method for demounting and mounting of high-pressure self-sealing manhole

A technology of special tools and disassembly methods, applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems such as laborious, time-consuming, operator injury, etc., and achieve the effects of simple structure, fast assembly, and reduced maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

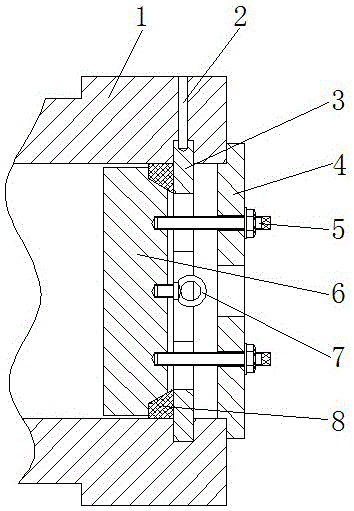

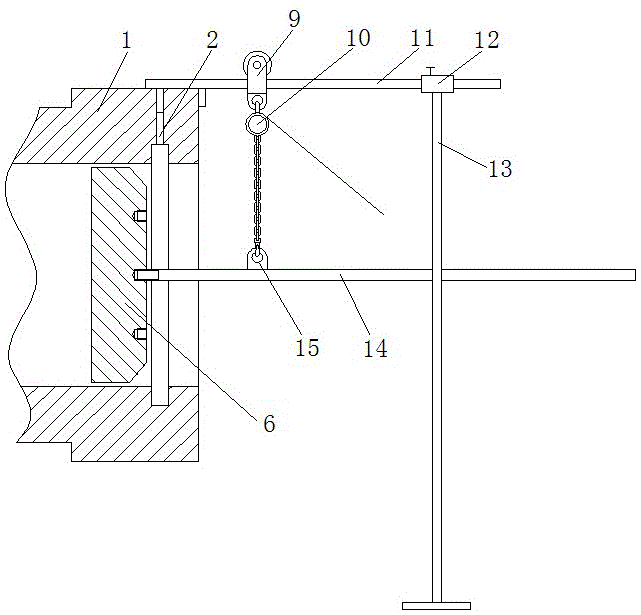

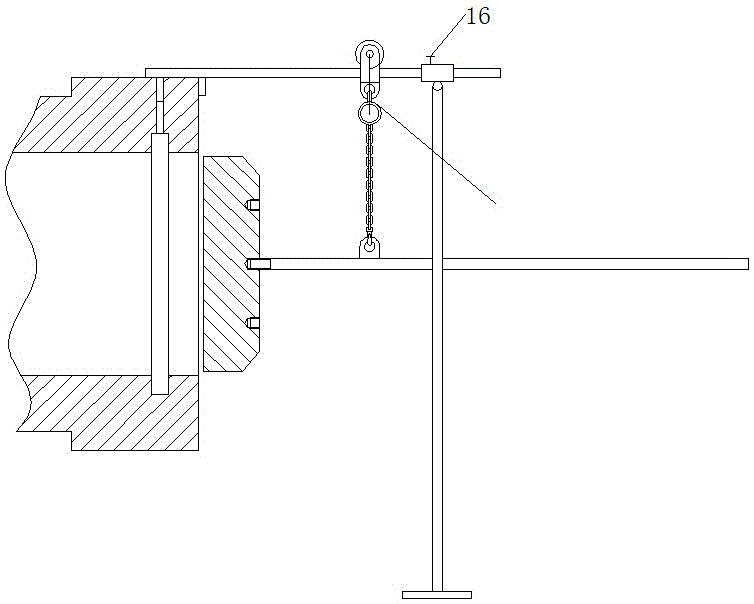

[0027] Such as Figure 1-6 As shown, when it is necessary to inspect and repair the interior of the high-pressure vessel, first fix the fixing screw 5 on the self-sealing manhole of the quadruple ring, the holding ring 4, the quadruple ring 3, the sealing ring 8, and the lifting ring screws on the manhole sealing cover 6. 7 Remove in order, and then insert the positioning pin 11-1 at the left end of the beam 11 in the special tool for disassembly and assembly of the high-pressure self-sealing manhole into the bolt hole 2 of the fixed quadruple ring at the upper end of the circumference of the manhole 1. To improve the stability of the beam, a positioning plate 11-2 is fixed on the beam corresponding to the end of the manhole, and then the pulley block 9 is installed on the beam, the other end of the beam is inserted into the sleeve 12 at the upper end of the column 13, and the fixing screw is used 16 Fix the beam with the column; screw the threaded end of the extraction rod 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com