Recovering machine for installing marine assembling pipes and recovering method

A closed tube, marine technology, applied in applications, auxiliary devices, household appliances, etc., can solve the problems of long manufacturing time, low manufacturing precision of the closed tube, complicated process, etc., and achieves improved accuracy, good equipment versatility, and efficient process. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

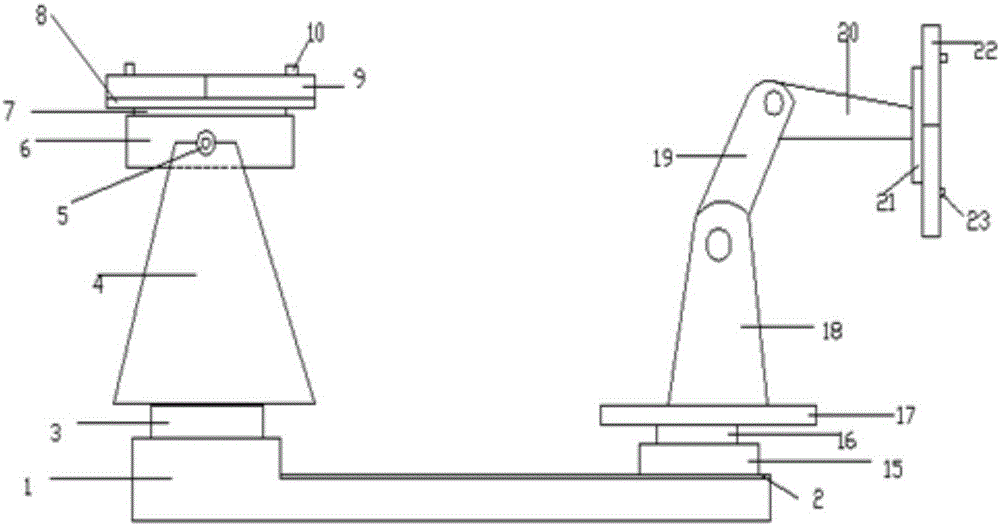

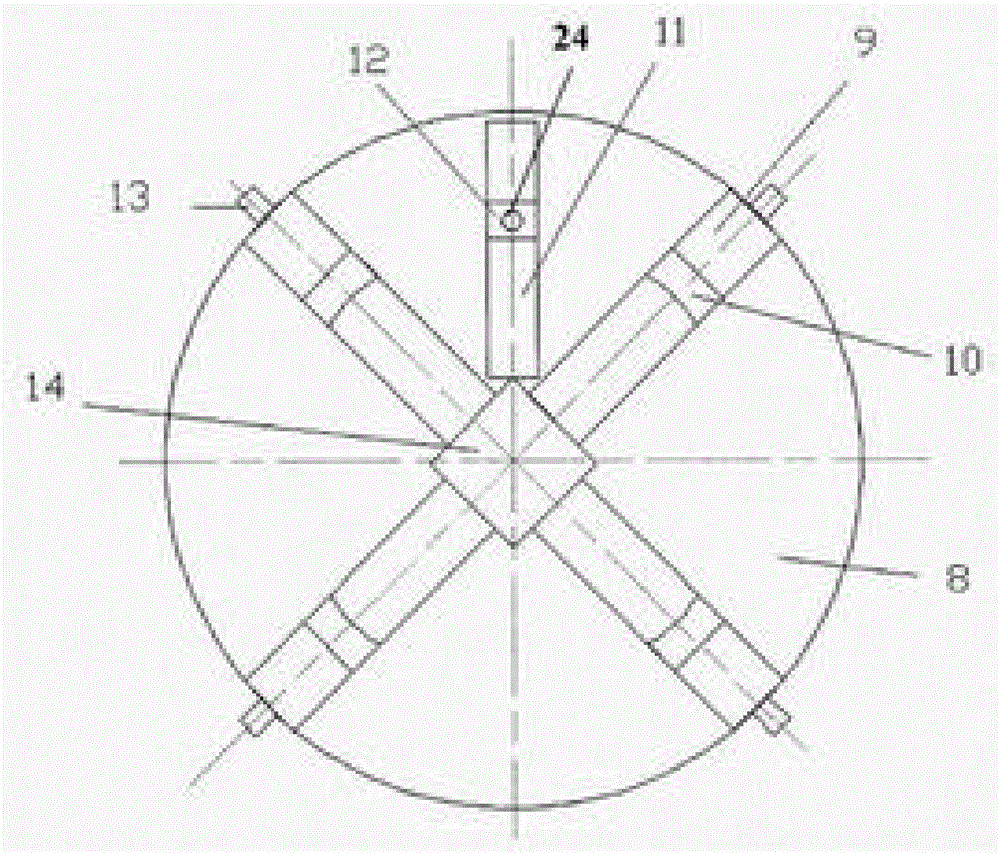

[0036] figure 1 and figure 2 As shown, a reproduction machine of the present invention for the installation of marine folding pipes includes a base 1 on which a guide rail 2 is installed, and one end of the base 1 is provided with a head frame rotating shaft 3, and the head frame rotates A head frame 4 is installed on the rotating shaft 3, and a head frame turning platform 21 is hinged on the head frame 4. The head frame turning platform 21 is provided with a head frame chuck rotating shaft 16, and a head frame chuck rotating shaft 16 is equipped with a head frame chuck 8. , the head frame chuck 8 is provided with a clamping mechanism; the guide rail 2 is provided with a robot arm base 15 moving along the guide rail 2, a chuck rotation shaft 16 is installed on the robot arm base 15, and a robot is installed on the chuck rotation shaft 16. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com