Centering butt joint positioning supporting device for vertical type stirring friction welding storage box assembly annular seam

A technology of friction stirring and positioning support, which is applied in auxiliary devices, welding equipment, welding equipment, etc., to improve welding efficiency, ensure high precision, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

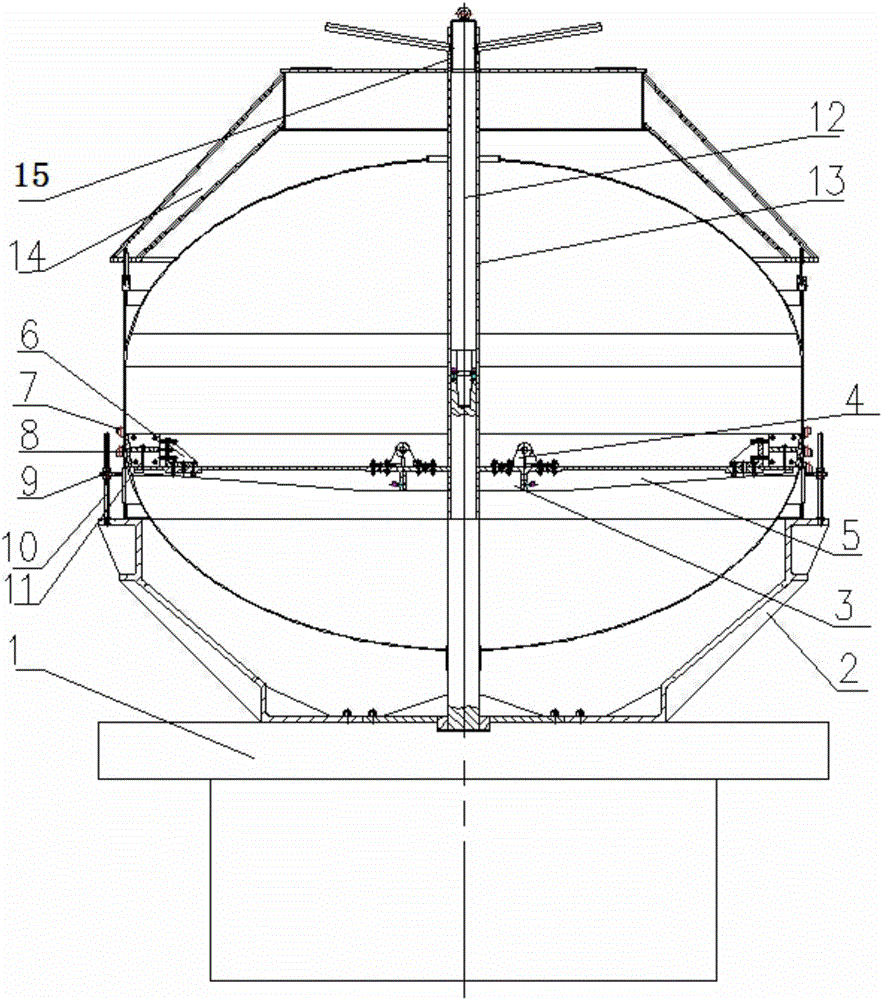

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] This device is to ensure the assembly accuracy during the friction welding of the general assembly of a certain type of storage tank, so that the assembly gap and the stagger amount are less than 0.2mm.

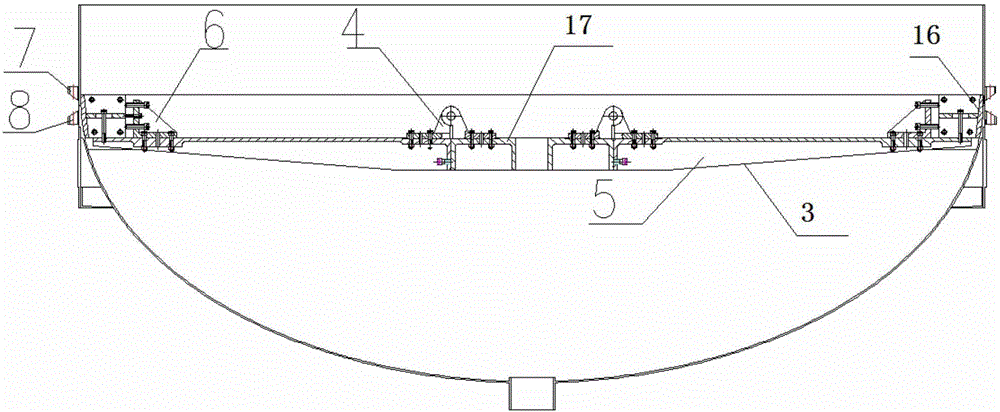

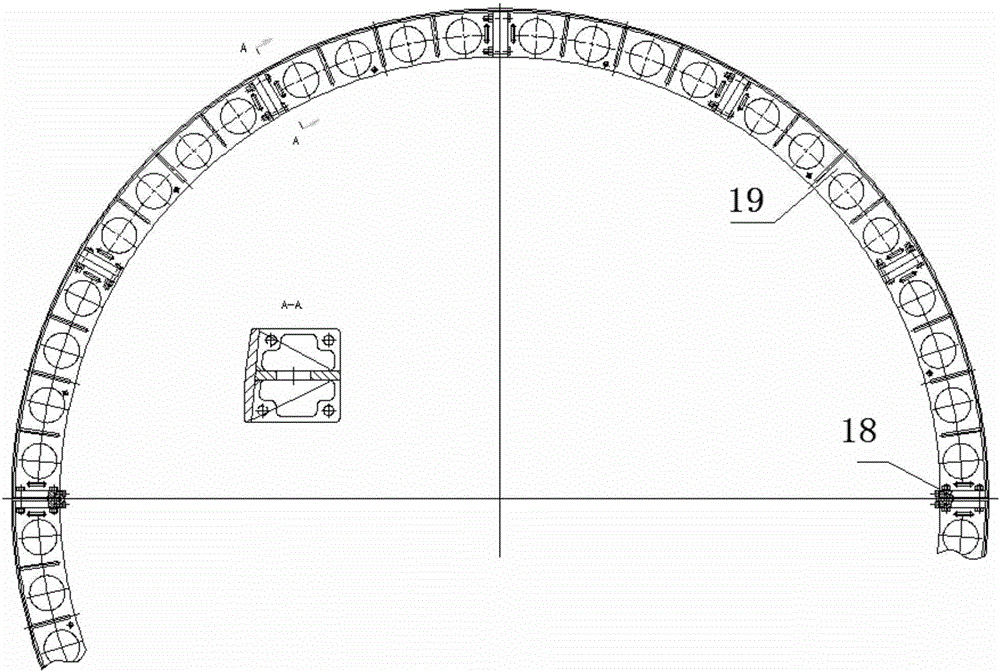

[0031] Such as figure 1 Shown is the overall schematic diagram of the friction stir welding process equipment for the general assembly of storage tanks. It can be seen from the figure that a vertical friction stir welding centering and positioning support device for the general assembly of storage tanks includes a positioner base 1, a base 2. Ring seat 3, inner support tensioning structure 11, barrel section outer hoop assembly 7, fork outer hoop assembly 8, support plate 9, adjustment screw 10, mandrel 12, support sleeve 13, compression cover 14 and compression Wheel 15; wherein, the displacement base 1 is located at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com