Round tube flanging trimming device

A trimming device and flanging technology, which is applied in the field of mechanical processing, can solve problems such as low production efficiency, complex structure, and inability to perform continuous trimming, and achieve the effect of ensuring trimming quality, light application range, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

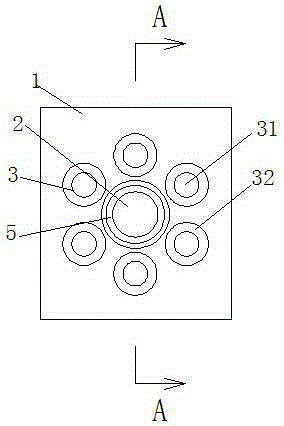

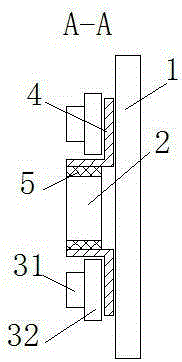

[0017] The present invention comprises frame 1, and described frame 1 is provided with rotating wheel 2 and pressing wheel 3; The mode that described rotating wheel 2, pressing wheel 3 are set meets: rotating wheel 2 is arranged in the middle, and pressing wheel 3 is arranged to rotate The wheel 2 is the center and several rings are arranged, and the pressing wheel 3 can move radially relative to the rotating wheel 2, and the gap formed by the pressing wheel 3 and the side wall of the frame 1 is for the circular pipe flanging 4 to enter. The pressing wheel 3 can move horizontally relative to the side wall of the frame 1.

[0018] The rotating wheel 2 is covered with an elastic wheel 5 that rotates synchronously with the rotating wheel 2 .

[0019] The pressing wheel 3 is arranged in steps, including a small wheel 31 on the outside and a big wheel 32 on the inside coaxially arranged, and the gap formed by the big wheel 32 and the side wall of the frame 1 is used for flanging th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com