T-pipe-structured ultrasonic cleaning in place device

An in-situ cleaning, three-way pipe technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as shedding, quality, safety disputes, residual dirt on the pipe wall, etc., to improve quality. and yield, avoiding slow cleaning and reducing the number of cleanings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

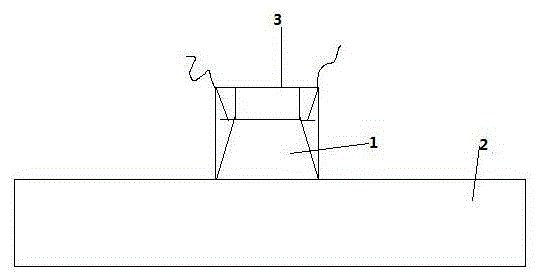

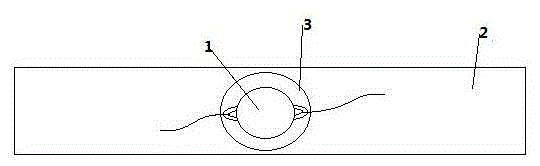

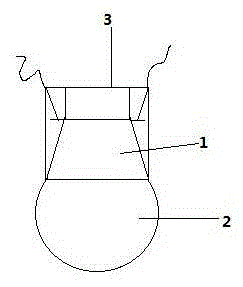

[0013] Embodiment: The ultrasonic in-situ cleaning device with a three-way pipe structure shown in the figure includes an ultrasonic vibrator 1, a three-way pipe 2, and a sealing cover 3. It is characterized in that: the ultrasonic vibrator is connected to the transducer and the horn The whole is a commonly used standard component. The ultrasonic transducer consists of a central piezoelectric ceramic element, front and rear metal cover plates, prestressed screw rods, electrode sheets and insulating tubes. The tee is made of commonly used plumbing pipes of the same material and diameter as the piping system. The ultrasonic vibrator and the branch pipe of the tee pipe are bonded and fixed with AB glue. It is required to ensure that the plane of the vibrator is circumscribed with the inner cylindrical surface of the straight pipe of the tee pipe, so as to ensure the normal flow of liquid passing through the pipe and not affect the manual cleaning and dredging of the pipe. The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com